General Process

The model supports various routings involving for the following types of processes:

• 3D Laser

• Cut To Length

• Deslag

• Bend Brake

• Roll Bending

• Laser Cut

• Laser Punch and Plasma Punch

• OxyFuel Cut

• Plasma Cut

• Shear

• Turret Press

• Waterjet Cut

Cut To Length is a blade cutting process that cuts rolls of sheet metal to a given length. Cut-to-length lines unroll the sheet, level it, and cut to the desired length. Generally cut-to-length lines can handle stock 5mm or less in thickness.

Shear is a blade cutting process that supports straight edge cuts from sheet stock. Shears can be hydraulically powered, human powered, or use an electromechanical mechanism.

Deslag is modeled in aPriori as a manual process to remove slag after oxy-fuel or plasma operations, and is completed by a handheld grinder. Slag consists of by-products (mostly metal oxides and silicon dioxide) of the separation of the metal from its raw ore. Note that deburring is also available from secondary machining (Automated Deburr and Manual Deburr). Burs, in contrast to slag, are irregularities in the metal that result from cutting processes.

Bend Brake is a sheet metal process used after cutting to create straight or simple curved bends. Bend-brakes can be hand operated or driven (hydraulically or mechanically). This operation cannot form bend radii less than the thickness of the material.

Laser Cut is a flame cutting process typically used on thin sheet metal (up to 25.4mm thickness). A laser operates on a CNC basis--cutting parts based on an input file. This operation is very slow when cutting thick material, and may require a secondary operation such as deslag or shot blast. Laser machines are generally large, as they can handle large stock sheets (at least 4' x 8') of metal.

OxyFuel Cut is a flame cutting process typically used on thick sheet metal (up to 305mm thickness). It can be performed manually or as a CNC operation. CNC operations can have up to ten torches running in parallel. This operation is too powerful to cut thin material (since it causes part deformation), cannot achieve tight tolerances, and requires a secondary operation such as deslag or shot blast to clean up the cuts. CNC oxy-fuel cut machines are generally large, as they can handle large stock sheets (at least 4' x 8') of metal..

Plasma Cut is a flame cutting process typically used on medium thickness sheet metal (up to 77mm thickness) It can be performed manually or by CNC machines. aPriori only supports CNC machines. CNC machines can have two plasma heads running in parallel. This operation cannot achieve tight tolerances, and requires a secondary operation such as deslag or shot blast to clean up the cuts. CNC Plasma machines are generally large, as they can handle large stock sheets (at least 4' x 8') of metal.

Turret Press is a punching process that supports periphery cutting and hole making for thin (< 10mm) sheet metal. This operation is very slow when cutting thick material, and may require a secondary operation such as deslag, or a machining deburring process (Automated Deburr or Manual Deburr), or shot blast to clean up the cuts. Turret presses are CNC controlled and can be driven mechanically, hydraulically, or with a combination of both. Turret machines are generally large, as they can handle large stock sheets (at least 4' x 8') of metal.

Laser Punch and Plasma Punch are hybrid processes for combination machines which include both a turret press and either a laser or a plasma cutting head. The advantage of these processes is that parts with holes and complex shapes can have both operations completed without changing machines. Accuracy can also be enhanced as it is possible for alignment errors to be introduced when parts are moved between two different machines. Because these are combination machines, the individual cost factors for laser cutting, plasma cutting, and turret press punch are generally the same as for the individual processes.

Waterjet Cut is capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance. The cutter is commonly connected to a high-pressure water pump where the water is then ejected from the nozzle, cutting through the material by spraying it with the jet of high-speed water. Additives in the form of suspended grit or other abrasives such as garnet can assist in this process. Although Waterjet Cut may result in higher costs when compared to Laser Cut or Plasma Cut, Waterjet may be preferred when the materials being cut are sensitive to the high temperatures generated by other methods. Waterjet Cut does not create a "heat-affected zone" (HAZ), so Waterjet Cut allows metals to be cut without harming or changing their intrinsic properties. Note: Because Waterjet Cut tends to be more expensive than other processes, aPriori typically does not automatically choose it. You should select it manually if you feel that the benefits listed above are worthwhile in your situation.

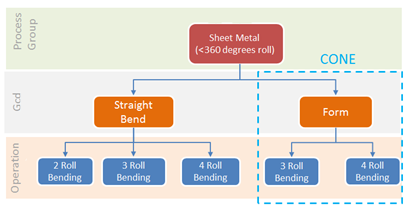

Roll Bending handles bend diameters that are too large for Bend Brake. The Sheet Metal roll bending process is similar to the process available for Bar & Tube (see Bar & Tube Fabrication Process Group on page 147) except that Sheet Metal:

• handles only non-360 degree tubes

• does not support laser tube welding and re-rolling

• can automatically select roll bending machines (Bar & Tube Fab must have manual machine selection)

• can handle conical bends

For Roll Bending to be selected, the component must have at least one straight bend.

Three rolling processes are available:

• 2 roll bending

• 3 roll bending with initial pinch

• 4 roll bending with double pinch

Conical bends are supported by 3- and 4-roll bending.

If you have licensed the appropriate modules, your routing can include optional machining, turning, heat treatment, surface treatment, and packaging processes.

See Process-level Routing and Process-level Feasibility for more information.