Open the Investigation tab to see suggestions regarding the design that could help reduce cost, including DTC (Design to Cost) and DFM (Design for Manufacturing) improvement suggestions, for the selected process group:

These GCDs present opportunities to improve cost and manufacturability of the scenario as best practices, listed as Topics in the left pane of the tab.

View Topic Details

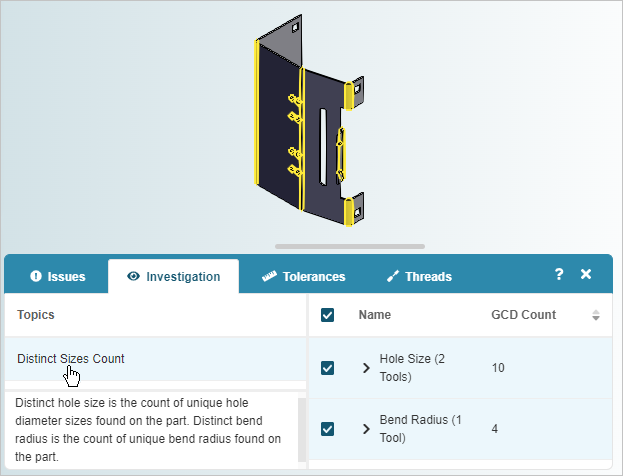

When you select the name of a topic, a description appears in the left pane of the tab and the applicable GCDs appear in the right pane of the tab and in the Viewer:

For this example, the Distinct Sizes Count description shows that:

-

Distinct hole size is the number of GCDs (GCD count) in the component that have unique hole diameter sizes.

-

Distinct bend radius is the number of GCDs (GCD count) in the component that have unique bend radius sizes.

The node table shows that two different tools are required to drill 10 holes while one tool is required to make four bends.

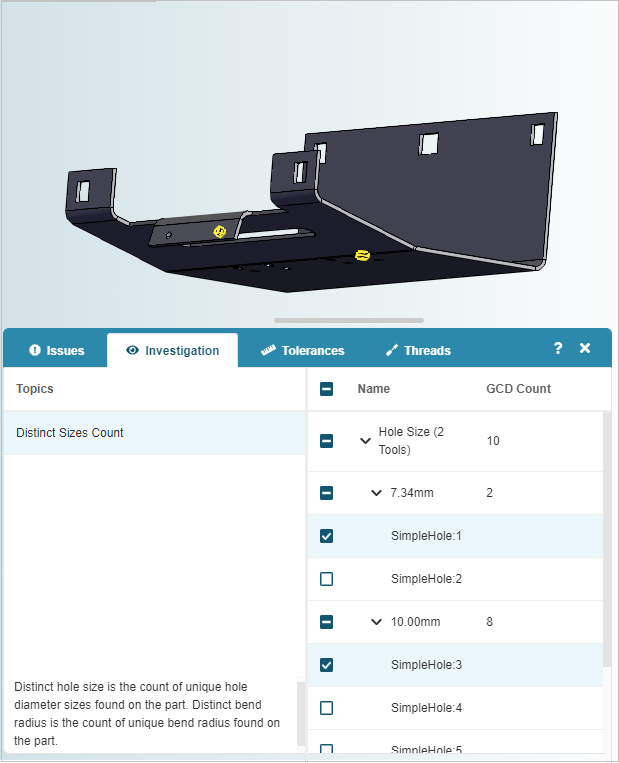

To further investigate the topic for hole GCDs, expand the nodes, and select several GCDs:

This shows that two tools are required because two holes have a 7.34 mm diameter while eight holes have a 10.00 mm diameter. If all 10 holes have the same diameter, they can be made with one tool instead of two. Using fewer tools typically reduces cycle time, and therefore, manufacturing cost.

Design Review

After you examine these GCDs, you can see whether you should change the design, asking questions such as:

-

Does changing the design so that all holes have the same diameter violate the requirements?

-

If not, will changing one or more diameters have a positive, a negative, or no impact on the design or manufacture of other parts in the assembly or batch?

-

Will changing the design prevent the parts from being used as spares for preexisting assemblies?