Alternative Designs

After you determine which components have savings opportunity, you can compare the approximate costs of two or more potential designs for that component.

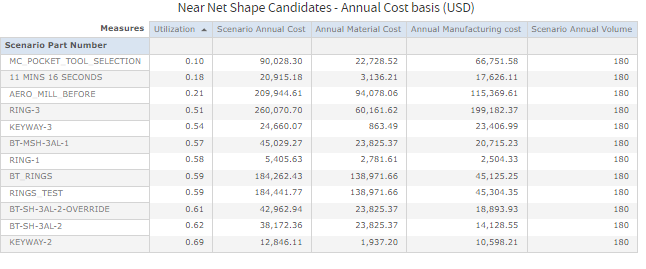

For example, you may have completed a Near Net Shape (NNS) analysis on a set of Machined parts – below – and noticed that two of the top three parts are good candidates for NNS.

After you decide which components are worth exploring further, you can open them using aP Design.

Example - High-end Bicycle Part

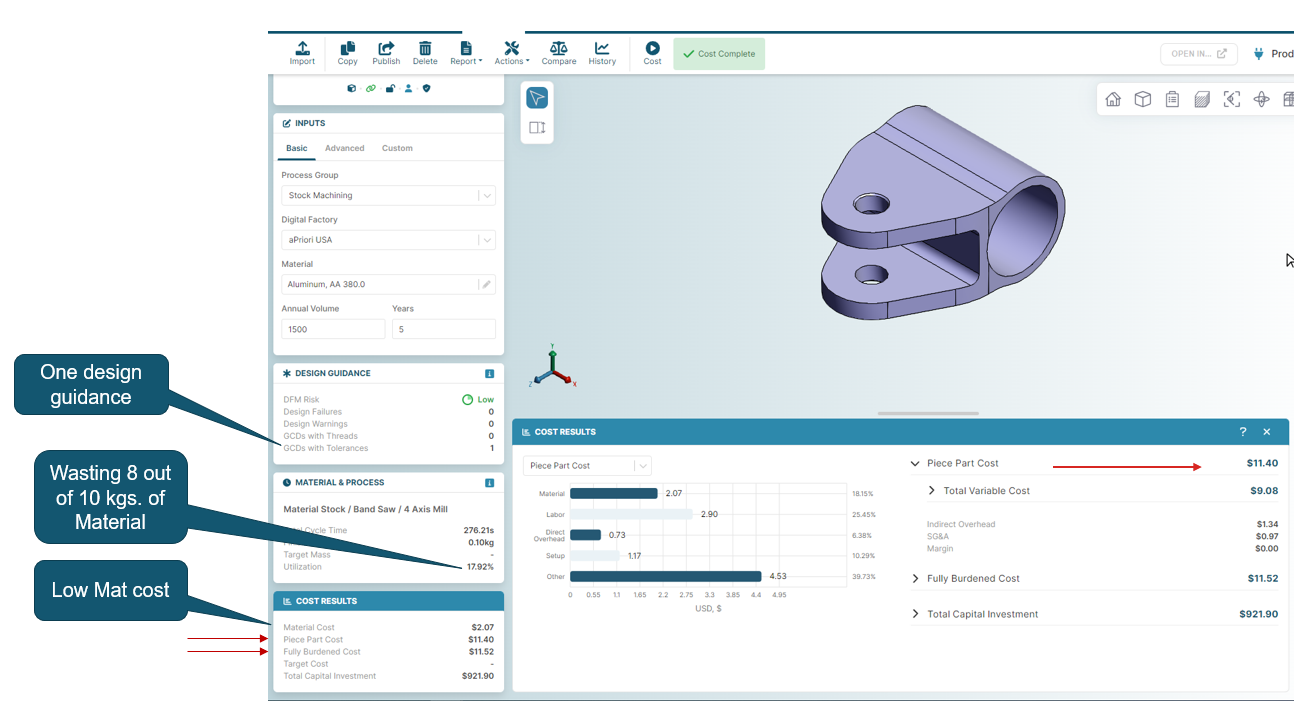

Using aP Design, we will examine a high-end bicycle part. We have adjusted the annual volume to a more reasonable number for this type of product – 1,500 per year.

You can see the initial cost of the bicycle part and the cost breakdown.

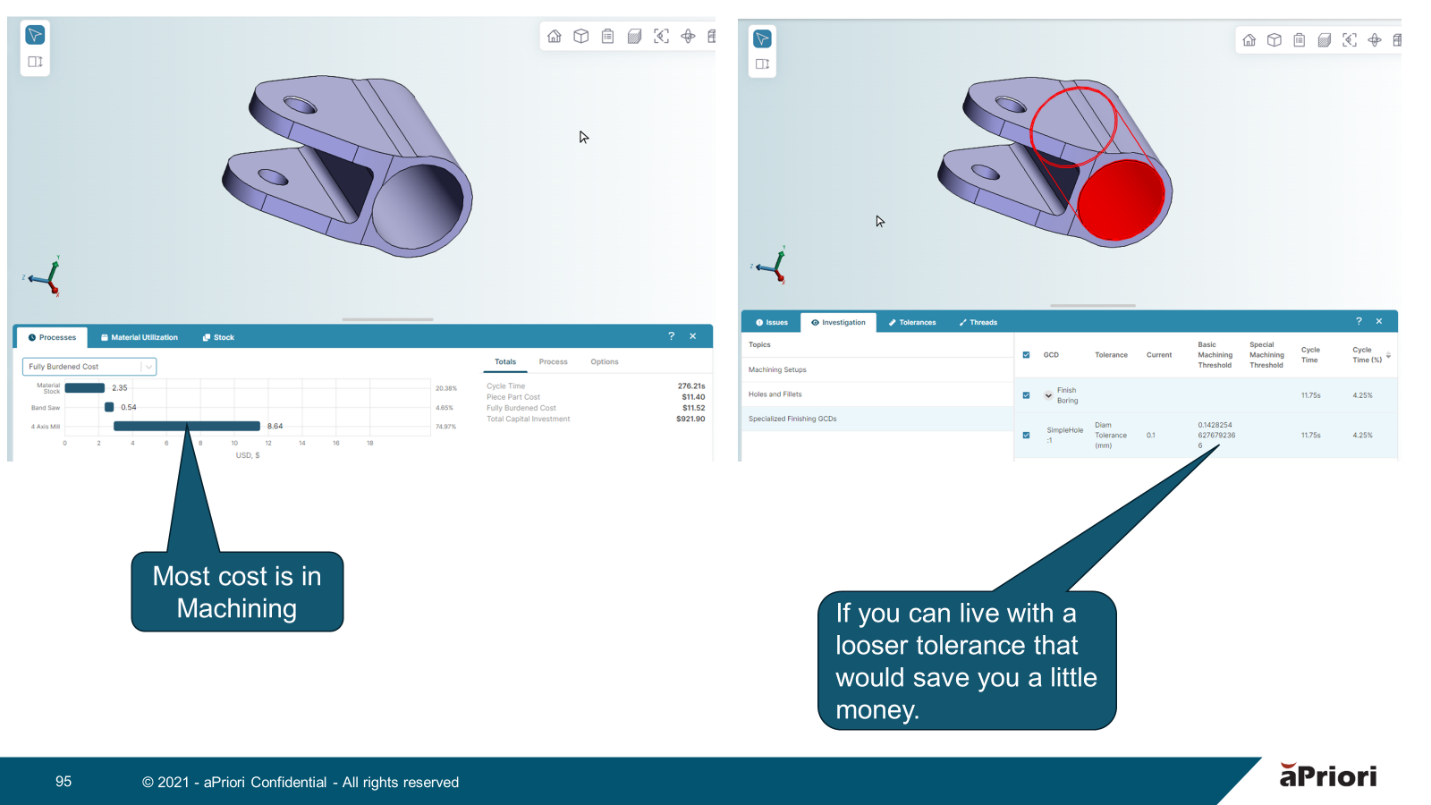

You can also investigate further to see where most of the manufacturing cost is going. As there is a lot of material being wasted here, and there is high potential to save on manufacturing costs, it’s worth spending 10 minutes exploring some alternatives. If not, at the very least, you now know that it may be worth exploring the tolerance of that hole.

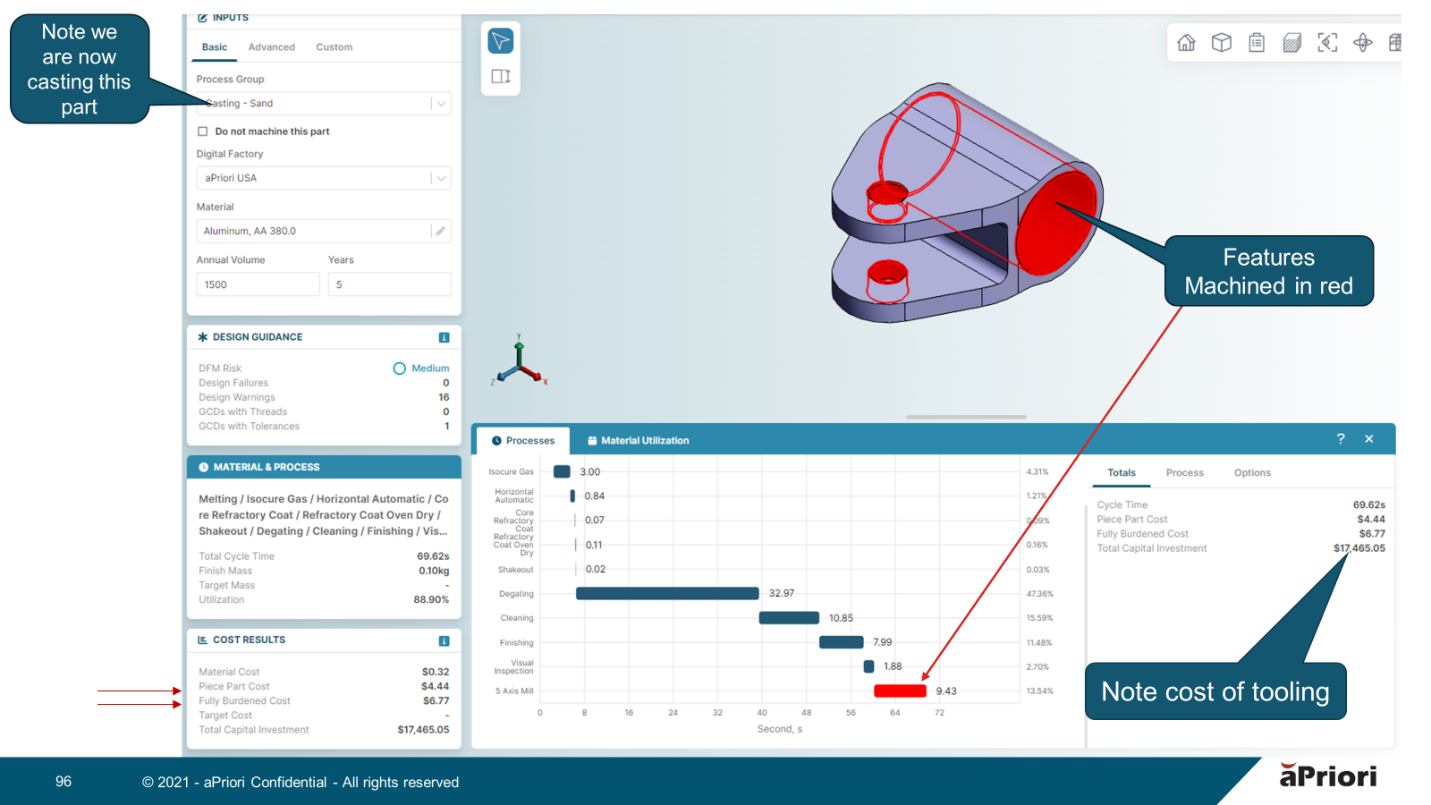

Let’s explore casting the part:

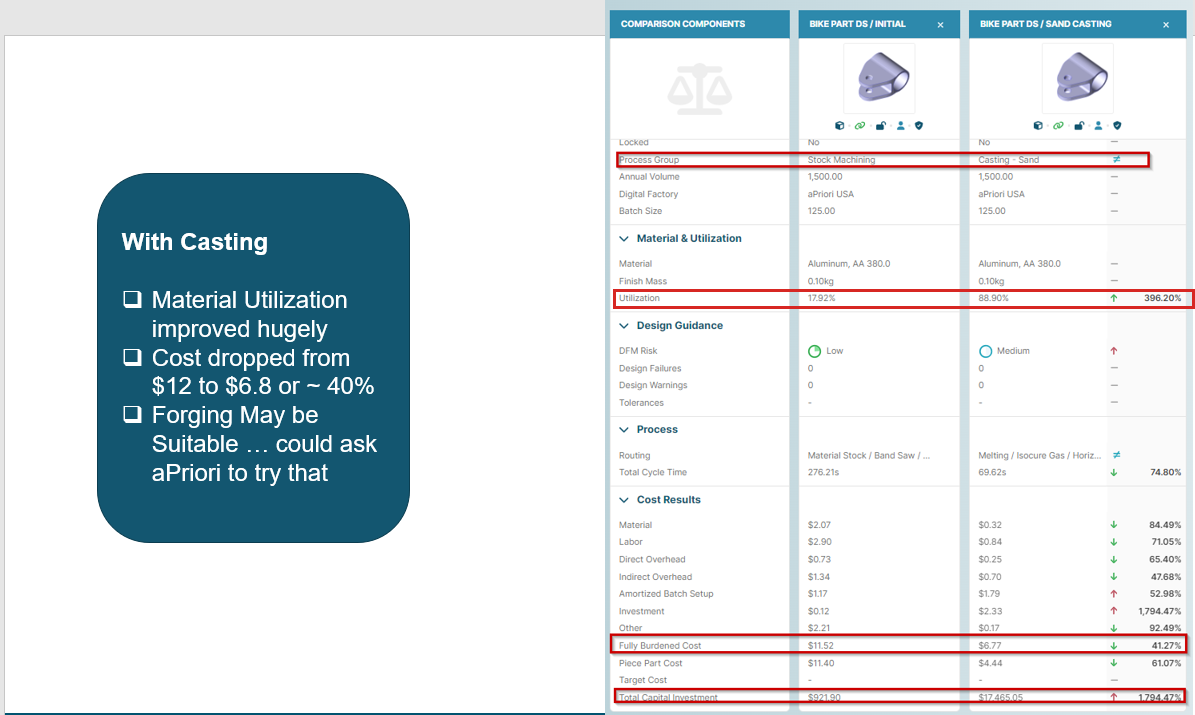

Finally, you can see both design options together in a comparison view (also available with aP Pro), that includes two alternatives, Stock Machining and Sand Casting.

Next Steps

So, we have found about $7,125 in annual savings. This amount may not be sufficient to warrant a re-design effort; however, had this been an NPI/NPD part, you would probably want to go the Casting route.

Common Questions When Redesigning Components

Work through the candidates of parts and consider different redesign approaches

-

Can assemblies be replaced with a single part or reduced number of parts?

-

Can Sheet metal fabrications be replaced with a single formed component?

-

Can different materials be used (for example, stainless steel instead of steel to avoid painting)?

-

Can plastic molding parts be used to replace metal parts or even small assemblies such as brackets?

-

Can we avoid unnecessary machining operations – like grinding by reviewing components for over-tolerancing?

You will need to create and import 3D CAD models for some of these alternatives, then analyze them in aP Design, then compare the total Fully Burden Cost (FBC) and DFM risk.

Alternative Approach - aP Pro

You can also use aP Pro to evaluate alternative designs - see the Alternative Designs tutorial for aP Pro.