Design for Sustainability

How to Incorporate CO2e Impact into Design

In this example, we will explore how to evaluate design alternatives by comparing cost and carbon dioxide equivalent emissions (CO2e).

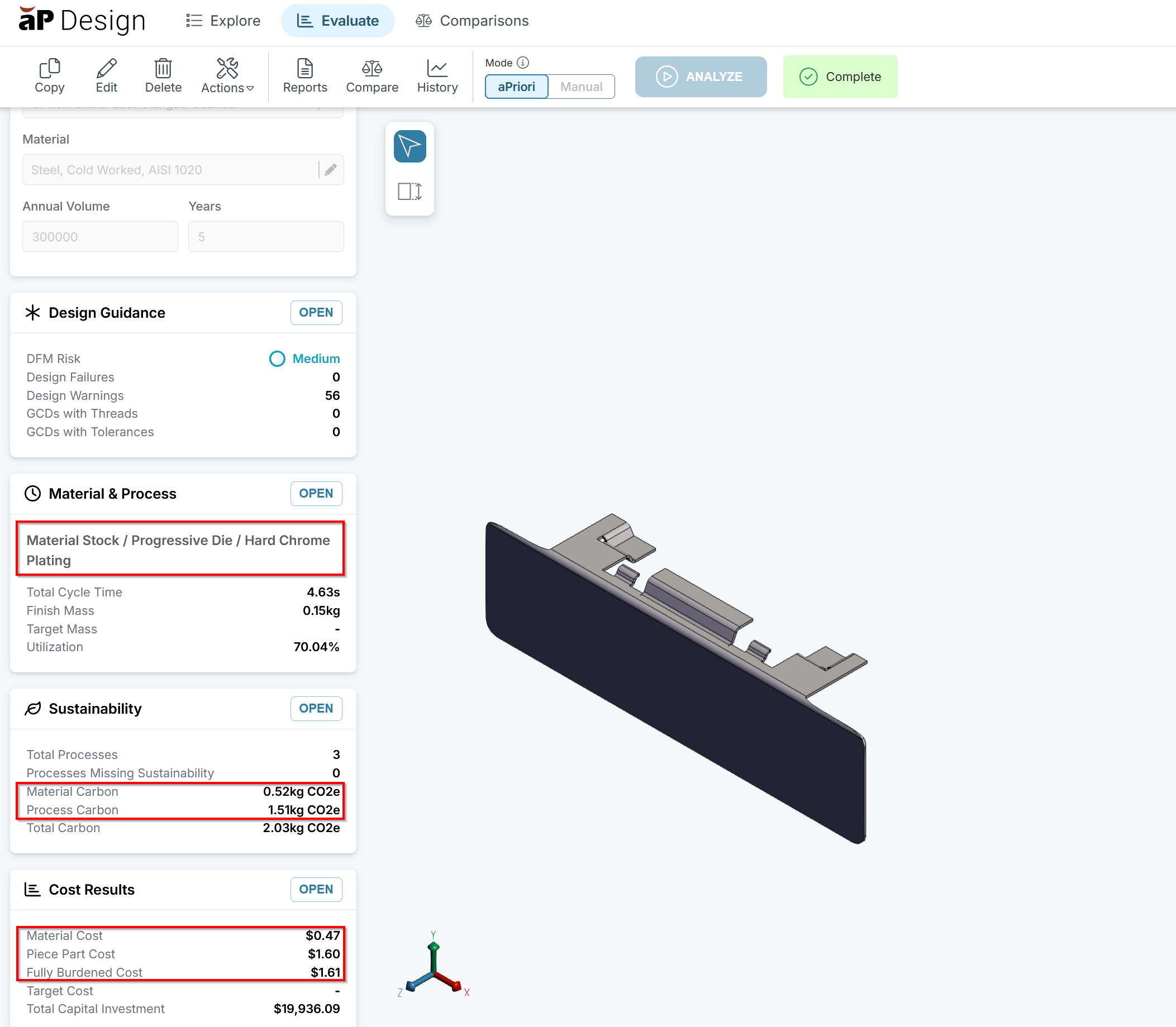

The part is an end cap on a light assembly and remains visible when the assembly is in service. The estimated annual volume is 300,000 units.

Initial Analysis

The first design iteration is made from sheet metal. Since the part is visible during service it also has a chrome coating.

-

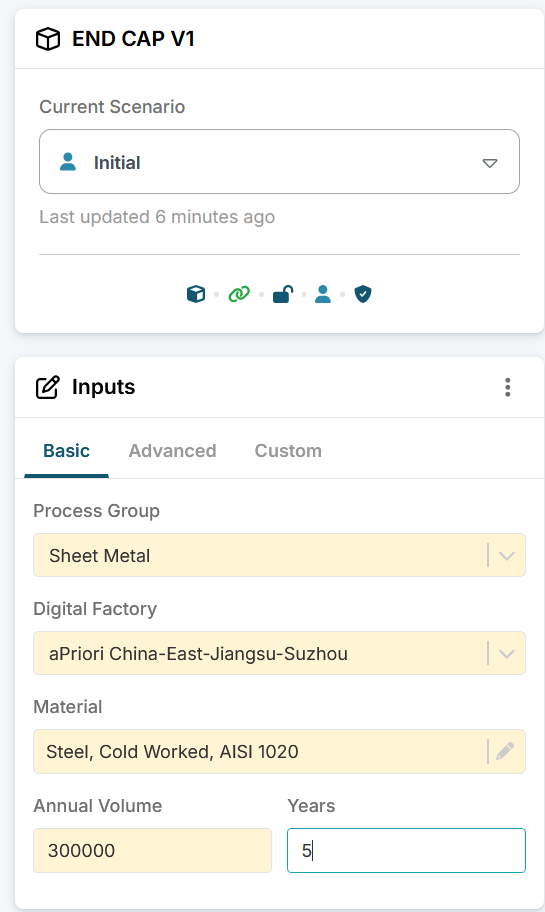

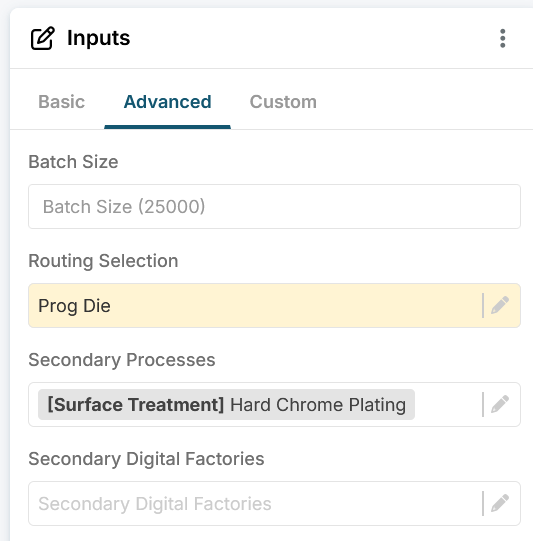

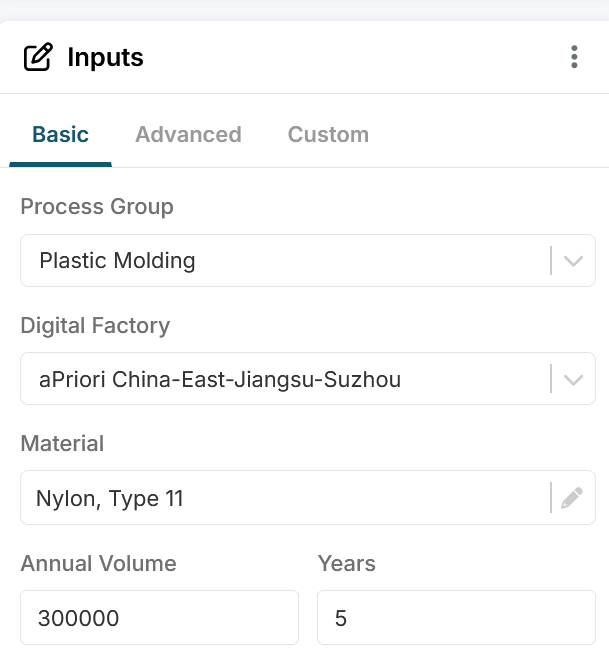

Analyze the part in aP Design with the following input settings.

-

aPriori selects a progressive die routing and calculates the CO2e of both the material (including material scrapped) and processing. aPriori also estimates the cost of the part.

Evaluate Design Alternatives

One idea to reduce cost is to change the part from metal to plastic. Before investing time to redesign the part to be suitable for injection molding, we want to get a directional assessment if the cost decrease will be worth the time. We also want to ensure the CO2e is not higher than the current design.

-

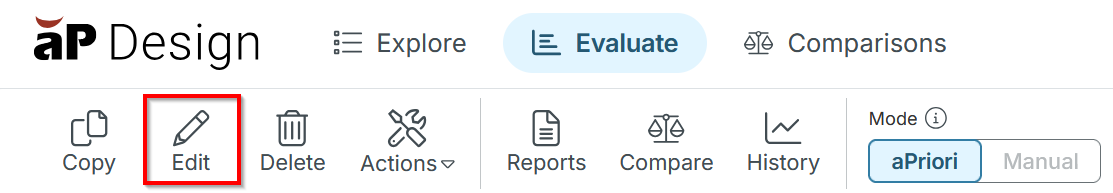

Without making any changes to the design, click the Edit button to copy the scenario to your private workspace to edit.

-

Change the process group to Plastic Molding. We are opting for a Nylon material with the same chrome finish.

-

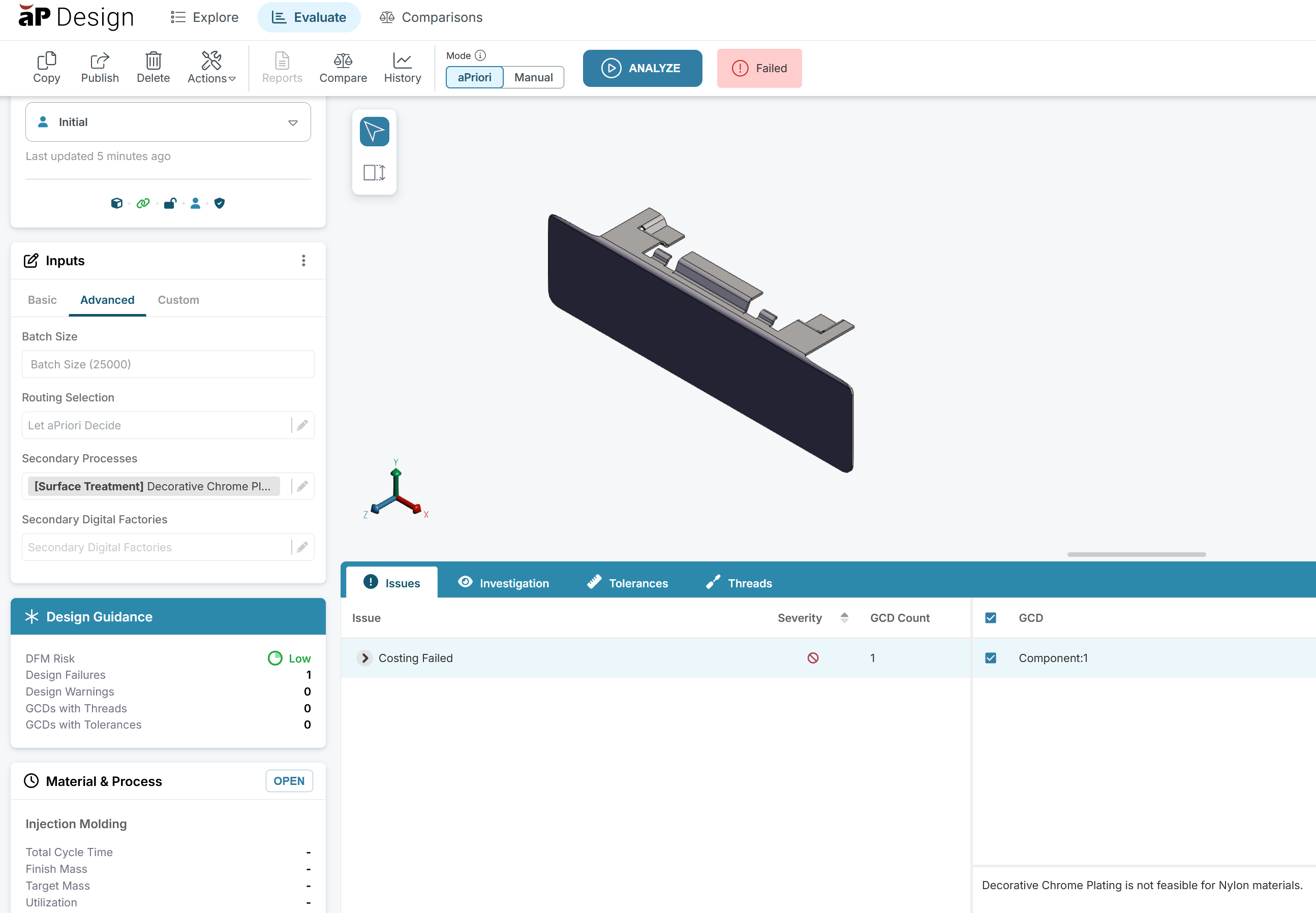

The part has now failed to analyze in aPriori. The view will pop up with a description of the issue. Evidently chrome plating is not feasible for nylon materials.

-

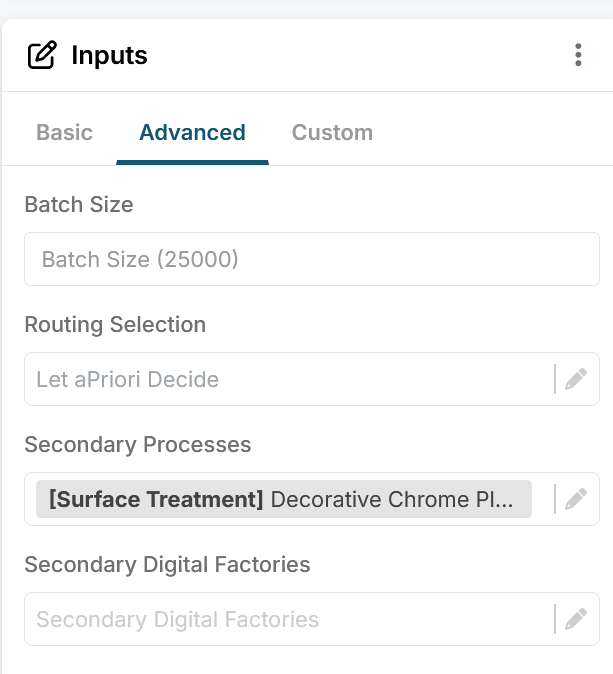

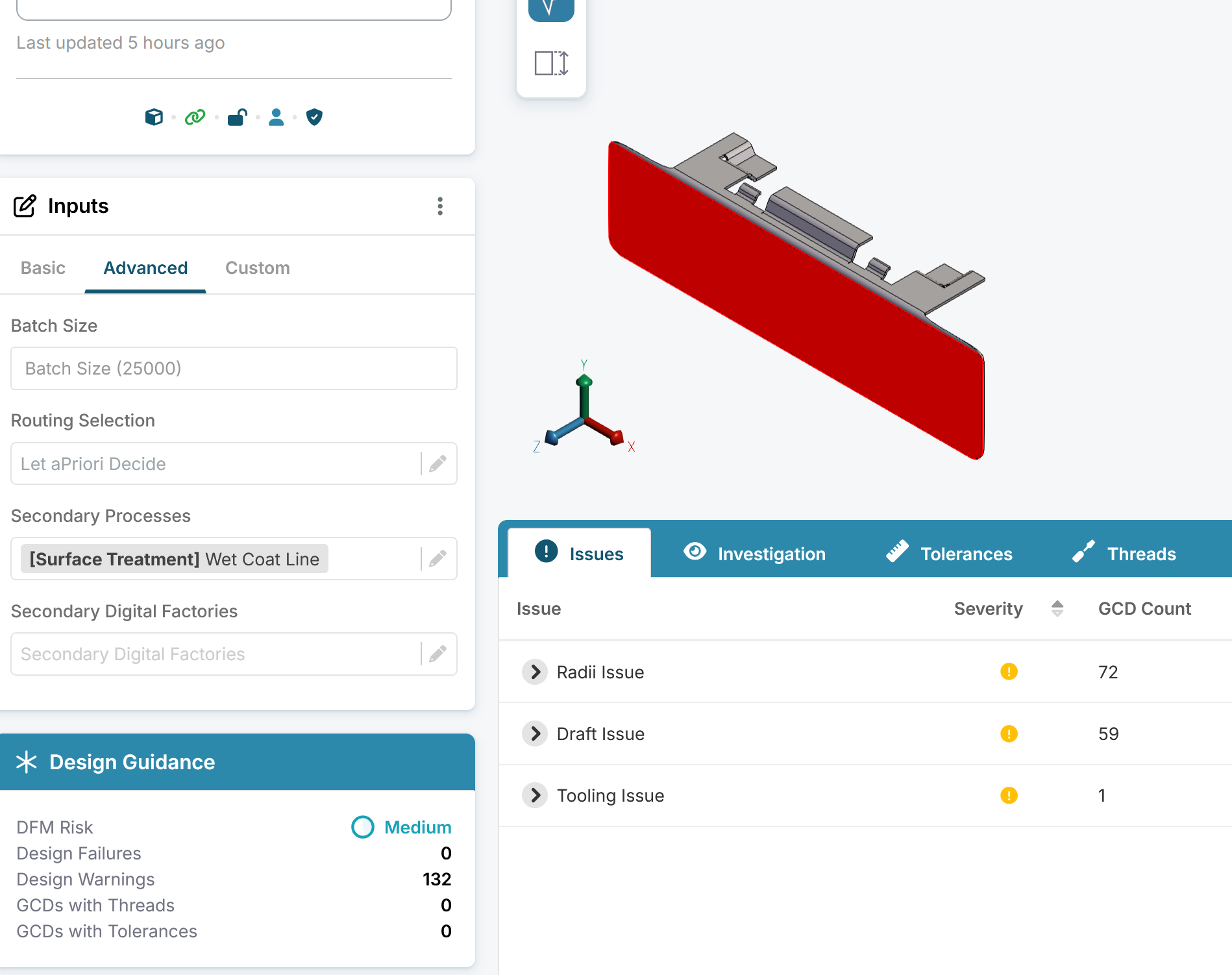

Instead of plating the part we will try painting it. In Secondary Processes, select the Wet Coat Line surface treatment and analyze again. aPriori identifies a number of manufacturability issues due to the design not having draft angles or radii. We will fix those if we determine the cost savings are worth pursuing.

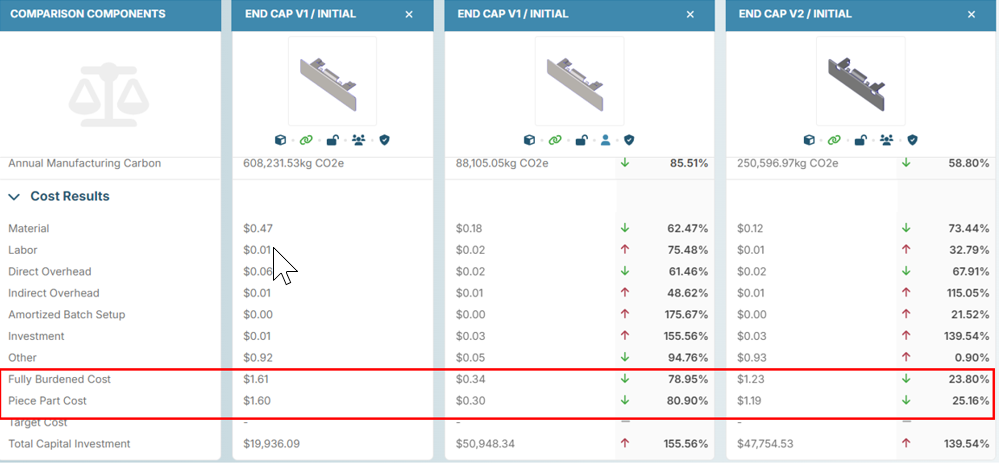

Compare

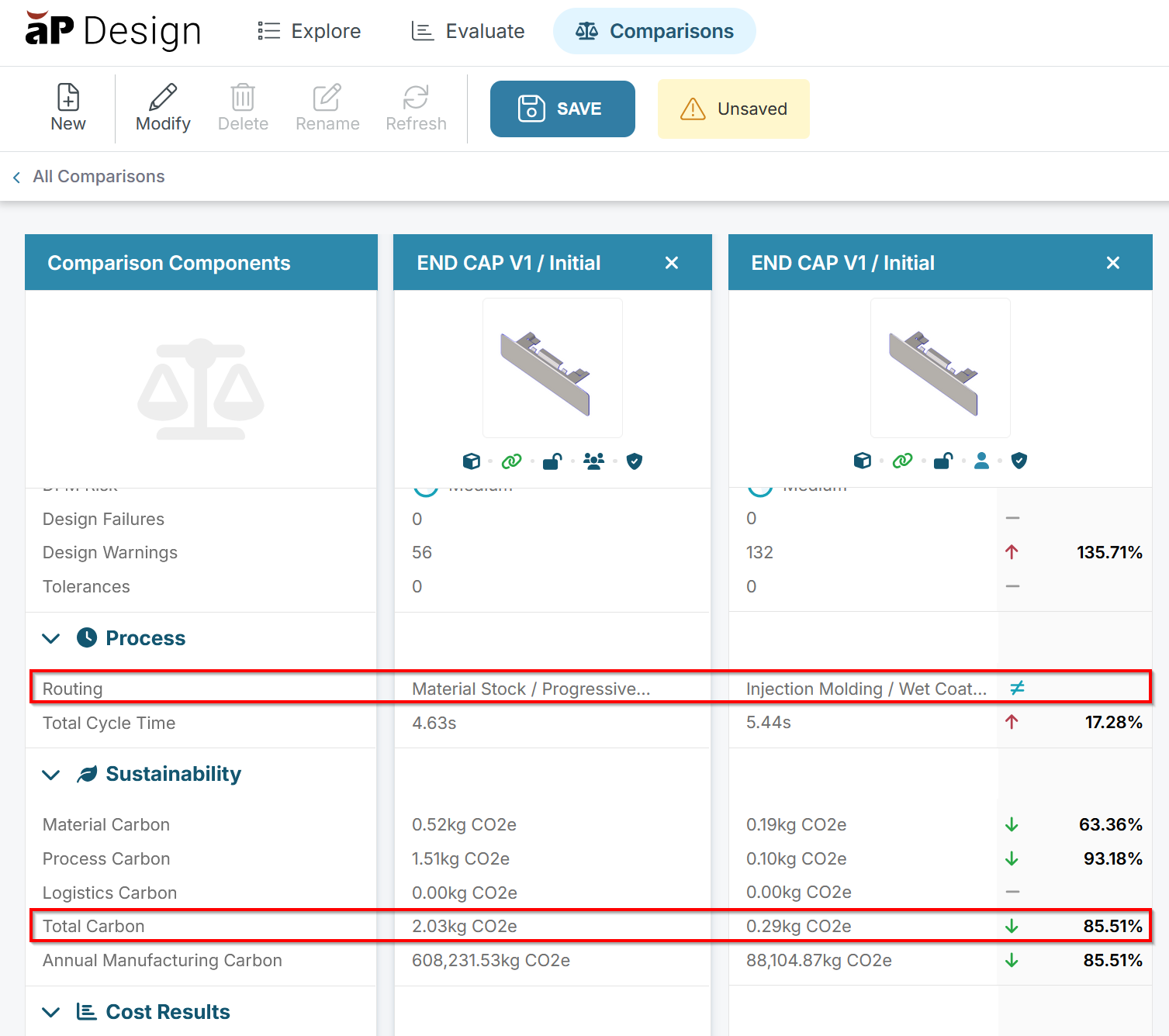

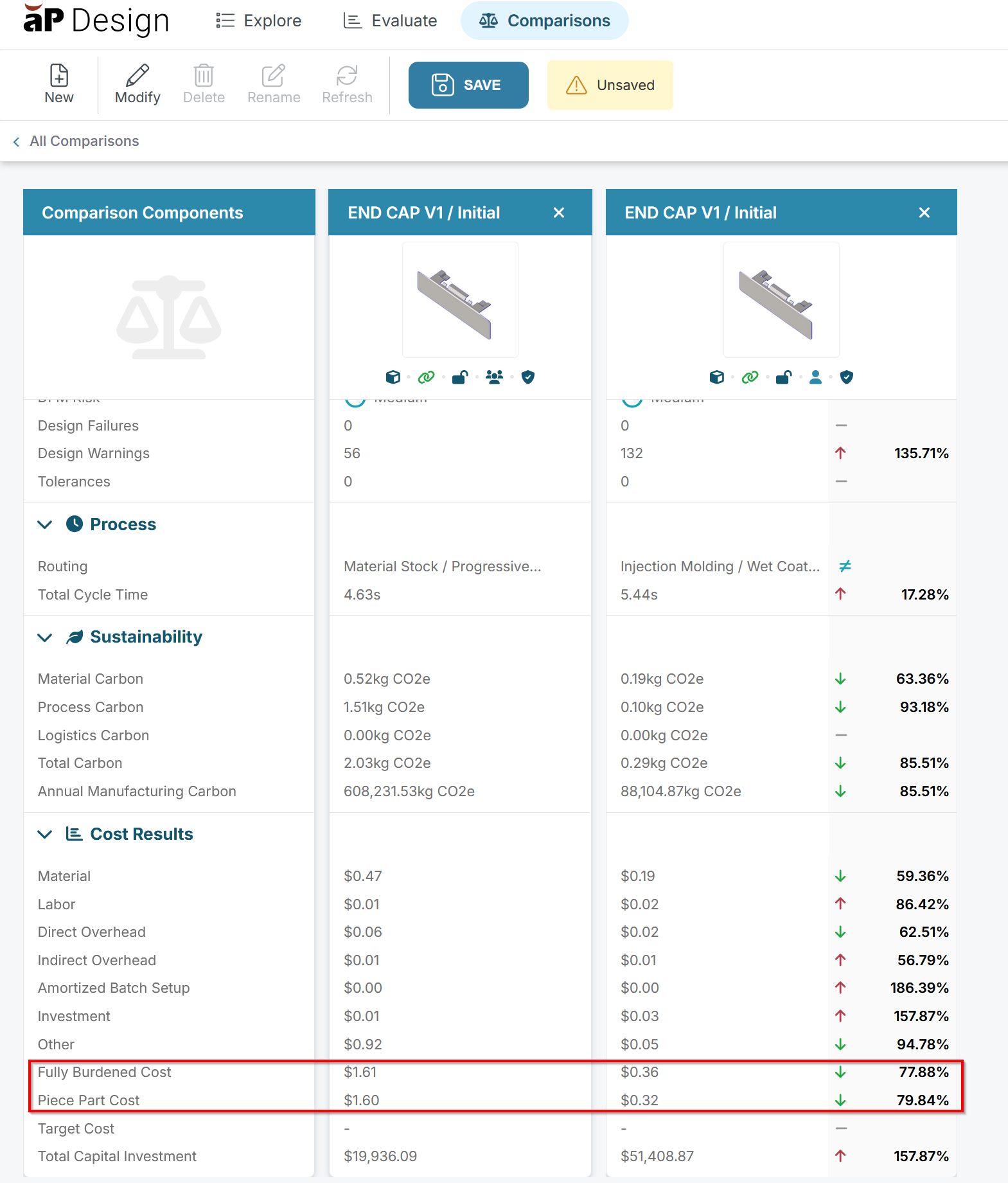

Now that we've explored both the sheet metal and plastic design options, we can compare them side by side to evaluate cost and CO2e impact.

Click the Compare button to compare the original sheet metal scenario and the plastic scenario side by side.

The first sheet metal design is on the left. We can see the CO2e is significantly lower for the injection molding scenario.

The piece part and fully burdened cost is also significantly lower. With this business case we can request additional resources to optimize the part for injection molding. However, the Product Manager is concerned about the paint finish instead of chrome plating. A colleague suggests using Acetal which can be chrome plated.

Further Design Alternatives and Comparison

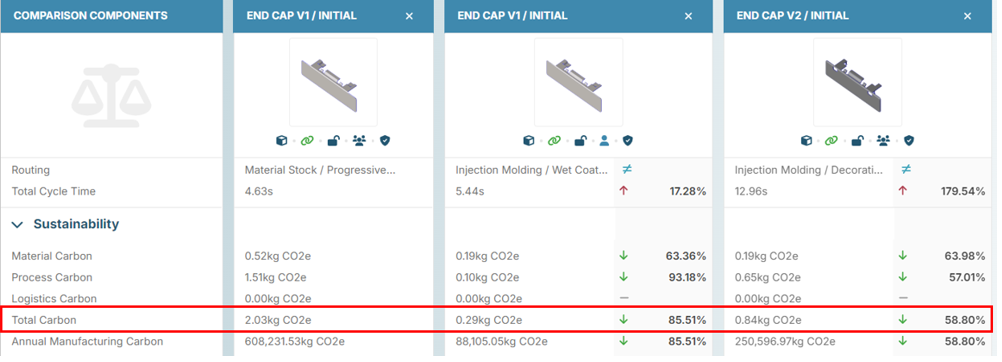

To explore additional possibilities, we can refine the design further and evaluate its impact on cost and CO2e.

-

Edit the CAD model to add radii and draft angles, then import the updated model into aP Design and analyze it with Acetal and chrome plating.

-

Add this new scenario to the comparison. The CO2e and cost is higher than the painted Nylon version (middle) but still lower than the original sheet metal design (left).

Next Steps

We have determined the Acetal design with chrome finish is worth pursuing further. From here, we start determining what other assumptions in manufacturing may further reduce the CO2e impact, such as number of cavities in the tool.