What’s new for Electronics Costing Modules 2023-11

This section covers the following topics:

PCBA and Wire Harness Costing Time Improvements

The performance of the PCBA and Wire Harness modules was significantly improved, resulting in much faster initial costing and re-costing performance for PCBA and Wire Harness assembly scenarios with hundreds or thousands of components.

aP Pro 2023 R1 SP3 and the 2023-11 Electronics Modules enable users to analyze PCBA and Wire Harness assemblies much more quickly than in previous releases. Initial costing times have been reduced between 60% and 80%, while recosting times have been reduced by 97% or greater.

Note: Previously, re-costing times for large BOMs were sufficiently long that aPriori advised against re-costing PCBA and Wire Harness assemblies, advising users to instead create a new scenario with any modified inputs. This guidance no longer applies, and users now are advised to re-cost scenarios instead of creating unnecessary new scenarios.

These performance gains were achieved by changing when aPriori saves scenarios for individual components in the BOM and updates the display in aPriori. Previously, as each component scenario was cost, it was saved automatically and the BOM display was refreshed. Now:

-

Individual component scenarios no longer are saved automatically. Users must explicitly save the component scenarios; this can be accomplished by selecting Scenario > Save > Scenario and Children from the aPriori menu bar. Alternatively, if you try to close the assembly scenario without saving component scenarios, aPriori will prompt you to save the Assembly and All Children.

-

• The BOM display is not refreshed until all components are cost . You will not see any components listed in the display until the entire BOM has completed costing, however the status bar will show incremental progress

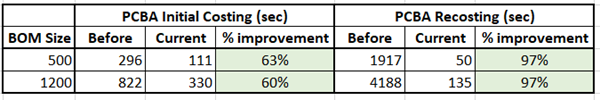

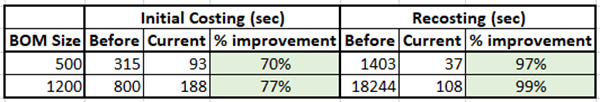

The tables below show some representative costing and re-costing performance improvements for BOMs of two different sizes. Note that these results correspond to an environment in which the aPriori client and database were installed on the same machine. The absolute costing and re-costing times you experience in practice will vary, depending on your environment and the latency between the client and database. However, the percentage improvement (compared to prior releases of aPriori) will be similar.

-

Comparison of PCBA costing times in aP 2023 R1 SP3 (Current) vs. aP 2023 R1 SP1 (Before):

-

Comparison of Wire Harness costing times in aP 2023 R1 SP3 (Current) vs. aP 2023 R1 SP1 (Before):

Several installation steps are required to leverage these performance improvements for PCBA or Wire Harness:

-

Upgrade your aPriori client to aP Pro 2023 R1 SP3.

-

Import the updated PCBA or Wire Harness Display Configuration Files (also referred to as the PCBA /Wire Harness “macros”).

-

Import the 2023-11 versions of the PCBA and Wire Harness Digital Factories.

-

Import the PCBA or Wire Harness RDLs 2023-11.

For more detailed instructions, refer to the PCBA Installation Guide version 2023-11 or Wire Harness Installation Guide 2023-11.

To access these latest files please contact your aPriori account representative or aPriori Support.

Additional Wire Harness Enhancements

In release 2023-11, the aPriori Wire Harness manufacturing process model was updated to resolve a number of issues, improve ease of use, and add extra validation to ensure accurate costing of a BOM:

Enhanced Validation and Time Estimates for Wire Dressing Components

The Wire Harness 2023-11 release provides more robust and accurate out-of-the-box capabilities for validating BOM inputs and estimating cycle time and cost for wires and dressings, based on their length.

This release introduces multiple improvements for length-based validation and time estimates for wire and dressings:

-

The out-of-the-box Wire Harness manufacturing process model now supports and correctly interprets multiple units of length for wire, twisted wire, and dressing components. Previously, the out-of-the-box model assumed all lengths were specified in millimeters; aPriori consultants often configured the model to support additional units of length. Now the out-of-the-box model supports the use of FT, IN, M, and MM units. As a result of this enhancement, costs will increase for components whose length was specified in a unit other than millimeters, for customers using out-of-the-box/non-configured models.

-

aPriori now requires the BOM to include both the length value and unit of length for wire, twisted wire, and dressing components. These components will fail to cost if either the length or unit of length is not specified. Previously aPriori did not fail or provide a warning if the length value was missing, resulting in neglecting the cost of these components and their associated assembly operations.

-

aPriori now checks that the unit type specified in the BOM is appropriate for the given component type, and fails to cost the component when the unit type is not compatible. For example, a Cable Tie (D1) component should have unit type Each (EA); if instead a length unit type is specified, aPriori now fails costing and notifies the user to update the BOM field.

Improved Estimates for Branch Covering and Branch Layout

This release improves automatic inclusion of Branch Covering and improves cycle time estimates for Branch Layout.

The Wire Harness 2023-11 release fixes two errors in the Branch Covering and Branch Layout process estimates:

-

The Branch Covering process now automatically is included if the Wire Harness BOM includes Heat Shrink tubing, Split Looms, or Spiral Wrap dressings. Previously branch covering was neglected for these components.

-

The Branch Layout cycle time estimate was fixed to properly estimate Cable Tie cycle time based on the number of cable ties; previously it incorrectly referenced the number of spot wraps instead of cable ties. The result of this change can increase or decrease the calculated cost depending on the number of cable ties in the BOM compared to spot wraps.

Streamlined Workflow for New BOM Evaluation

The Wire Harness 2023-11 release streamlines the workflow for evaluating a new BOM.

Previously, a user first had to click on Wire Harness, then select Import New Formatted Wire Harness from the Select Wire Harness Mode dialog. Now, when no wire harness assemblies are already open, a single click on Wire Harness directly opens the main dialog, Import Formatted Wire Harness.

PCBA Resolved Issues

The PCBA 2023-11 release resolves several small issues discovered in prior releases.

This release resolves the following issues:

-

The Potting process has been enhanced to support the Formula Dependencies dialog. Additionally, the Potting machine properties Oven Load Time, Oven Unload Time, and Oven Cure Time have been renamed to Load Time, Unload Time, and Cure Time to reflect that Potting is a bench process, not an oven-based process.

-

The values of selected machines fields were corrected for clarity:

-

For the Screen Printing machine JUKI K3-II, the Max PCB Width field has been changed from 9,610 mm to 610 mm. This change does not impact cost estimates.

-

For the SMT Autoplacement Ultra High-Volume virtual machines, the Max Chip Deposition Rate values previously were too low and have been increased. These fields are informational, so the change does not impact cost estimates. Cycle times are computed using the Chip Deposition Rate field; those values were correct and have not been changed.

-