aPriori 2022 R1 includes a set of enhancements to the Casting-Die and Casting-Sand process groups. Collectively, these enhancements improve the accuracy of manufacturing operations assigned to the various part features and the clarity of the Design for Manufacturability feedback which is displayed, and provides better estimates of material utilization, cycle time, and cost. Various smaller tooling-related enhancements and fixes also are provided.

- Improved thickness assessment for castings

- Improved manufacturability assessment for Die-Cast and Sand-Cast parts

- Updated default "Castability" threshold values

- Improved manufacturing operation, cycle time, and material utilization estimates for Die-Cast and Sand-Cast parts

- Removed process setup options related to Design for Manufacturability

- Updated Trim Die Tooling Costs (Die Casting)

Improved thickness assessment for castings

aPriori 2022 R1 provides an improved algorithm for determining the thickness of a die-casting, sand-casting, or investment casting. Thickness information is used in a variety of ways including cooling time estimates and also in manufacturability assessments.

aPriori has updated the algorithm used in the Casting-Die, Casting-Sand, and Casting-Investment process groups for measuring the thickness of cast parts. By default, these process groups now compute thickness values using the same algorithm that already is used in the Plastic Molding, Assembly Molding, and Assembly Molding process groups. The updated algorithm produces more accurate results for the maximum thickness and average thickness values of cast parts.

The impact of the new algorithm depends on the specific part geometry and casting process. In a large set of Die Casting test parts, Maximum Thickness values increased by 0.51% on average while Average Thickness values increased by 20.18% on average. Die Casting Cooling Time estimates are based on Maximum Thickness and changed by 0.51% on average, and Fully Burdened Cost changed by 0.16% on average. Sand Casting cooling time estimates did not change because these currently are calculated based on part volume and surface area, rather than thickness.

Due to the improved accuracy of the new algorithm, aPriori recommends using the new algorithm. However, if desired, customers can continue to use the previous thickness algorithm by setting the site variable castThicknessAlgorithm to Legacy Voxel-Based. This site variable must be set separately for each process group (Casting-Die, Casting-Sand, and Casting-Investment).

Improved manufacturability assessment for Die-Cast and Sand-Cast parts

For the Casting-Die and Casting-Sand process groups, aPriori now determines whether a given GCD (feature) is fully cast, fully machined, or manufactured by a combination of casting and machining, based on the size and wall thickness of the GCD and the part material.

Previously aPriori considered only the fully cast and fully machined options, and the determination was not sensitive to part material. In the Casting-Die and Casting-Sand process groups, a new Manufacturability property now is provided for Simple Hole, MultiStep Hole, and Ring GCDs and displays how this GCD is manufactured:

- CAST

- MACHINED

- CAST_AND_MACHINED

aPriori automatically determines the Manufacturability of Hole and Ring GCDs, based on two criteria:

- The Diameter of a Simple Hole or the Width of a Ring

- The Wall Thickness around the Simple Hole or Ring

If the diameter or width of the GCD is too small, then Manufacturability is set to MACHINED. If the Wall Thickness is too small, then Manufacturability is set to CAST_AND_MACHINED. Otherwise, Manufacturability is set to CAST.

Note: The Manufacturability property also is displayed for Keyway and AxiGroove GCDs, but always has a value of MACHINED.

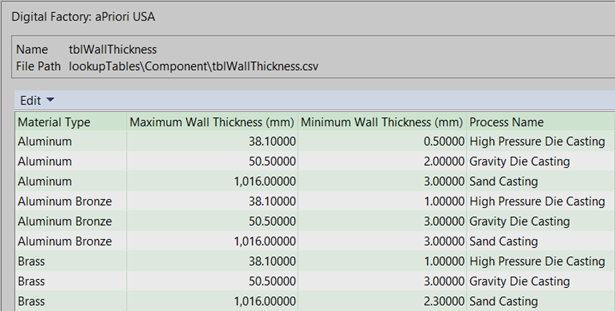

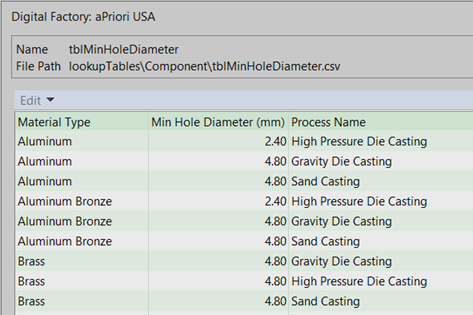

The thresholds for GCD size and wall thickness which drive the automated Manufacturability determination are specified in the lookup tables tblMinHoleDiameter and tblWallThickness. Note that the specific threshold values vary by part Material Type and casting process, as shown below. For example, a hole in an aluminum part must be at least 4.80 mm in diameter to be made by sand casting or gravity die casting alone, but can be made by high pressure die casting if it is 2.40 mm or larger.

Figure: tblMinHoleDiameter

Figure: tblWallThickness

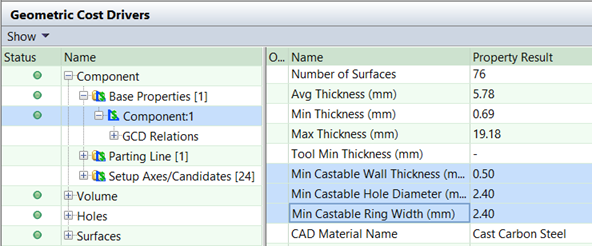

For convenience, aPriori displays the castability threshold values which were used to analyze a part as properties of the Component GCD (Min Castable Wall Thickness, Min Castable Hole Diameter, and Min Castable Ring Width):

Figure: Geometric Cost Drivers

Note: In the Casting-Die process group, since aPriori analyzes both the High Pressure Die Casting and Gravity Die Casting routings, aPriori will select the castability thresholds relevant to High Pressure Die Casting by default. If you explicitly select ("pin") the Gravity Die Casting routing, then the thresholds relevant to Gravity Die Casting will be applied.

If you do not agree with aPriori's determination of how a specific GCD is manufactured, you can override the Manufacturability property and set it to the desired value. Or, if appropriate, your Digital Factory manager can adjust the thresholds in the lookup tables to better match your expectations. This would affect the automated analysis of all parts.

Note: Overriding the value of a GCD's Manufacturability property will cause aPriori to re-extract GCDs when the part is next costed. This is because information such as part thickness measurements must be re-calculated, since they are affected if a GCD is assumed to be present in the raw casting vs. machined subsequently. In some cases, changing the manufacturability property can significantly affect Maximum Thickness and Average Thickness values reported in the Design Guidance displays. For example, if a large-diameter boss feature is set to (fully) MACHINED instead of CAST, aPriori will now compute the thickness of that feature assuming it is cast as a solid cylinder, with the interior hole being machined subsequently. Changing the part material also will cause aPriori to re-extract GCDs, if the threshold values for either GCD size or wall thickness are different between the new material and the previous material. If the two materials have the same "minimum castability" thresholds, then no GCD re-extraction will occur.

The Manufacturability property replaces the Is Castable property, which was displayed in previous releases of aPriori Professional.

Updated default "Castability" threshold values

As described earlier in these release notes, aPriori now considers part material when determining if small and thin-walled features can be cast or must be created by machining operations. However, default "castability" threshold values still apply in some cases, most notably for customers who have not yet upgraded their Digital Factory to use the most recent cost model version. These default values were updated in aPriori 2022 R1 so can cause a change in manufacturing operation assignment and thickness determinations.

As described earlier in these release notes, the "castability" thresholds used for a given part now depend on the part's material type, as specified in the lookup tables tblMinHoleDiameter and tblWallThickness. However, if the part's material is not found in the appropriate lookup table, or if the customer'sDigital Factory has not been upgraded to use the latest cost model logic, the castability threshold values are specified by the site variables described below.

- In the Casting-Die process group, the values of the site variables minCastableHoleDiameter and minCastableRingWidth were changed from 2.0 mm to 2.4 mm. The site variable minCastableHoleWallThickness was changed from 0.76 mm to 0.5 mm.

- In the Casting-Sand process group, the site variables minCastableHoleDiameter and minCastableRingWidth were changed from 6.4 mm to 4.8 mm. The site variable minCastableHoleWallThickness was changed from 5.0 mm to 3.0 mm.

These new default values align better with the recommended minimum values for the majority of casting materials in the aPriori Regional Data Libraries (as captured in the lookup tables tblMinHoleDiameter and tblWallThickness). That is, aPriori's analysis is more likely to be correct and better aligned with the Design Guidance provided for most parts, even for customers who do not upgrade their Digital Factory cost model version. As a result of these changes, the estimated thickness values and/or machining operations assigned to a part may differ somewhat from the previous release of aPriori.

To fully restore the behavior of the previous release, set the site variables isCastMachinedExtractionEnabled and enableMaterialTypeGCDExtraction to false, and set the site variables minCastableHoleDiameter, minCastableHoleWallThickness, and minCastableRingWidth back to their original values.

Improved manufacturing operation, cycle time, and material utilization estimates for Die-Cast and Sand-Cast parts

The cost model logic within the Casting-Die and Casting-Sand process groups was enhanced to better estimate the manufacturing approach and cycle time and material required to create small features and thin-wall conditions, aligned with the Manufacturability assessment of the feature geometry.

aPriori now assigns more appropriate and accurate casting and/or machining manufacturing operations to Simple Hole GCDs and Ring GCDs, based on the geometric manufacturability assessment of these GCDs described in the previous section as well as other considerations such as machine tool accessibility. GCDs which have a Manufacturability value of CAST will continue to be assigned As Cast or Coring operations. GCDs which have a Manufacturability value of MACHINED will be assigned only machining operations and no casting operations, meaning they are assumed to be fully machined out of the net-shape cast geometry. GCDs with a Manufacturability value of CAST_AND_MACHINED generally are assigned a sequence of both machining and casting operations. aPriori now also more accurately estimates the amount of material assumed to be present in the raw casting, prior to any machining operations.

For example, a thin-walled Simple Hole that is assessed as CAST_AND_MACHINED is assumed to be cast with a greater wall thickness than as modelled in the finished part (that is, one that meets the recommended minimum castable wall thickness threshold for the part's material). Rough Machining operations then are assigned to remove the additional material to produce the finished hole diameter. The specific type of Rough Machining operation assigned depends on the selected secondary machining process routing (for example, a Simple Hole would be assigned Rough Milling on a mill and Rough Turning on a lathe) and the GCD type (for example, Ring GCDs may be assigned Turning or Plunging based on feature dimensions and location).

When assigning manufacturing operations, the cost model also considers some additional criteria beyond the geometric Manufacturability value for a GCD, as described below:

- Accessibility: In High Pressure Die Casting, Ring GCDs that have adequate size and wall thickness but are not accessible from the draw direction or a side-action direction will have machining operations assigned, even when the Manufacturability value is CAST or CAST_AND_MACHINED. Other Casting processes may be able to use a Core in such cases rather than requiring machining operations

- Depth to Diameter ratio: Simple Hole GCDs that are too slender cannot be cast or cored reliably. The Manufacturability value does not account for this issue but the cost model logic does. In this case, aPriori will assign "fully machined" operations to the Simple Hole, even when the Manufacturability value is set to CAST or CAST_AND_MACHINED.

Known Limitation

In some less-common cases, a "full machining" operation cycle time and/or material removal assumption is calculated for a GCD designated as CAST_AND_MACHINED. For example, a hole that is not aligned with the part's turning axis but is machined on a 3-Axis Lathe or Mill-Turn machine may be assigned a Drilling operation which assumes the full hole volume is removed, thereby slightly overestimating the raw material required to make the part and slightly underestimating material utilization. Please refer to the aPriori Cost Model Guide version 2022 R1 for more details on these specific cases.

Compared to the previous release of aPriori, estimates of cycle time and Fully Burdened Cost will increase due the collected enhancements related to casting Manufacturability. These increases are due to parts with features that now are determined to require additional machining, due to thin walls or small opening sizes that restrict casting operations. Cycle times and expendable tooling costs increase in these cases. In a set of test parts, for High Pressure Die Casting, Fully Burdened Cost increased on average by 7.3%. For Gravity Die Casting, Fully Burdened Cost increased on average by 7.6%. For Sand Casting, Fully Burdened Cost increased on average between 12.0% for automated routings and 23.5% for manual routings.

Removed process setup options related to Design for Manufacturability

The Casting-Die and Casting-Sand cost models previously contained some process setup options which provided an early from of "design for manufacturability" feedback. These process setup options are now eliminated as they are replaced by the Design Guidance capability.

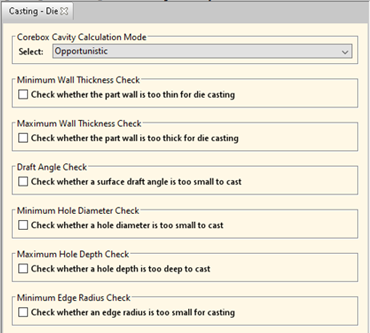

aPriori has eliminated six process setup options which previously could be used to fail costing of a GCD or the entire part, if various Design for Manufacturability best practices were violated. These process setup options were redundant; the Design Guidance tab now displays more actionable feedback for all of the issues concerned (and has for several releases). The process setup options Minimum Wall Thickness, Maximum Wall Thickness, Minimum Hole Diameter, Maximum Depth to Diameter, Draft Angle, and Minimum Edge Radius Check (Sharp Edge) no longer are available in the latest version of the cost model.

These options are shown below for the Casting - Die cost model, as they were displayed in a previous release of aPriori:

Figure: Casting - Die options from previous release

Updated Trim Die Tooling Costs (Die Casting)

aPriori 2022 R1 corrects an issue in which Trim Die tooling costs were underestimated.

aPriori 2022 R1 corrects an issue in which the raw material costs for various components of a Trim Die were neglected. The aPriori tooling estimates now account for the raw material cost of the following Trim Die components:

- Upper Die Shoes

- Lower Die Shoe

- Bottom Parallel

- Top Parallel

- Bottom Plate

- Blank adapter

- Die Block

- Die Block Adapter

Estimated tooling costs increased as a result of this fix. In a set of test parts, tooling costs increased an average of 2.35% for the Gravity Die Casting process and 2.18% for the High Pressure Die Casting process. Tooling increases observed for individual parts ranged from between 0.14% to 5.77%.