aPriori 2022 R1 provides multiple enhancements which improve the accuracy of Machining rough milling cycle time and cost estimates. These include better recognition and characterization of workpiece and part geometry which is to be rough-milled, and updated cost model logic to more accurately simulate how the tools would remove the material. The enhancements also add support for greater configurability and future extensibility of the cost model logic.

- Improved pocket recognition enables more accurate rough milling estimates

- Improved characterization of Stock Trim GCD enables more realistic and accurate estimates for machining material stock allowances

- More accurate Rough Milling cycle time estimates

Improved pocket recognition enables more accurate rough milling estimates

aPriori now recognizes more volumetric material removal features as Pocket GCDs, enabling aPriori to more accurately estimate the roughing end mill tool sizes, cycle time, and cost.

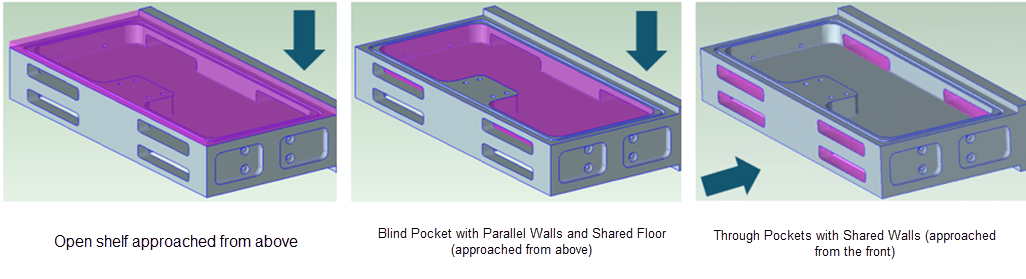

The following three types of geometries now are extracted by aPriori as Pocket GCDs:

-

"Open Shelf" - a layer of material that is not fully enclosed by walls - it may be unbounded on two or even three sides, as shown in the image below.

-

"Blind Pockets with Parallel Walls and a Shared Floor" - in this case, there are some undercuts in the walls of the pocket, so that a portion of the floor of the pocket spills into the undercut region. aPriori now virtually splits the floor and constructs a Pocket GCD which includes only the portion which is accessible from the common tool approach direction.

-

"Through Pockets with Shared Walls" - in this case, an undercut through a wall in the part shares a common surface with another material removal feature which is accessible from a different direction. In the picture below, aPriori now virtually splits that surface so that the undercut can be isolated and extracted as a "through" Pocket GCD.

Figure: Geometries that are extracted by aPriori as Pocket GCDs

In the previous release of aPriori, these types of geometries were not recognized as separate Pocket GCDs. They were included in the BulkRemoval GCD, which represents the total volume of material removed from the workpiece that is not represented as a more specific volumetric GCD (such as a Pocket, Slot, Hole, or Keyway). This Bulk Removal GCD is assigned a more generic Bulk Milling operation, which assumes a constant material removal rate and does not consider the specific tool size or depth of material to be removed. Now each of these volumes will be recognized as a distinct Pocket GCDs with properties that enable the determination of appropriate roughing end mill tool size and engagements, leading to more accurate cycle time and cost estimates.

Note: Other previous conditions for recognizing a volume as a pocket still apply. For more information on geometries that will or will not be recognized as a pocket, refer to the Pocket Recognition topic in the Stock Machining and Machining Process Groups section of the aPriori 2022 R1 Cost Model Guide.

Improved characterization of Stock Trim GCD enables more realistic and accurate estimates for machining material stock allowances

aPriori now extracts multiple distinct Stock Trim GCDs representing distinct stock allowances on different sides of the workpiece, and more accurately estimates the cycle time for rough milling these allowances.

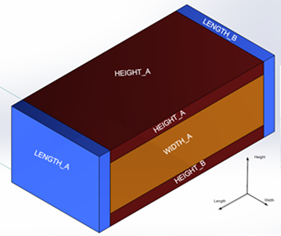

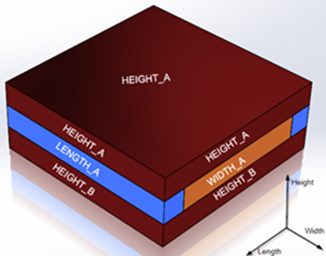

The Stock Trim GCD represents material allowances added to finished part dimensions to compute the raw stock size from which the part will be machined. For example, for a part machined from a rectangular bar or billet, there typically is some extra margin added on each side of the part's length, width, and height.

Previously, aPriori extracted these margins as a single Stock Trim GCD, even though it represented material margins on different faces of the workpiece. Additionally, rough milling operations and cycle time estimates for the Stock Trim GCD were somewhat simplistic and were not presented clearly. The volume of the single Stock Trim GCD was added to the BulkRemoval GCD volume and assigned a generalized Bulk Milling operation, which uses a single volumetric material removal rate and did not account for the actual setup axis/tool approach directions and tool sizes and engagements required.

In aPriori 2022 R1, multiple Stock Trim GCDs will be extracted for Rectangular Bar, Square Bar, Plate stock and Hex Bar stock. For Rectangular Bar, Square Bar, and Plate stock, six distinct Stock Trim GCDs will be extracted, representing "slices" or margins on the top, bottom, front, back, and sides of the workpiece. Equivalently, these margins are offsets on either side of the part bounding box height, width, and length dimensions.

The following images illustrate how the slices are oriented and sized, relative to the finished part bounding box dimensions, for Rectangular stock and Plate stock:

Figure: Rectangular stock |

Figure: Plate stock |

For Plate Stock, the Stock Trim GCDs are similar but the top and bottom stock allowances cover the full length of the workpiece.

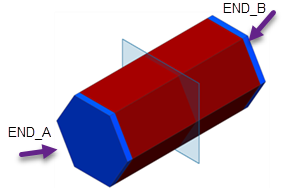

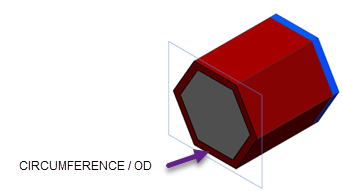

For Hex Bar, the number of Stock Trim GCDs depends on the selected process routing and machining preferences. There may be up to three Stock Trims - one on each side (hexagonal face) of the workpiece, and one around the "circumference" of the stock (actually encompassing six planar faces). If the default stock allowance "across the flats" is set to zero, indicating that the as-supplied stock surfaces are to be used, then there will be no Stock Trim around the circumference. If a bar-feed lathe routing is selected, there will be a Stock Trim GCD on the front hexagonal face but not the back hexagonal face, as this margin of material is removed by the part-off operation rather than a rough milling operation.

|

|

Figure: Stock trims

Now aPriori computes a distinct mechanistic Rough Milling operation assignment for each individual Stock Trim GCD. This includes determining the appropriate setup axis, tool size, and cut depth to remove the material and therefore results in more accurate cycle time estimates than the previous release. Also note that the multiple Stock Trim GCDs afford more configurability, for example, some customers may wish to configure a Shell Milling operation to be applied to large-area stock trims, while smaller-area stock trims would continue to use standard end mills.

More accurate Rough Milling cycle time estimates

The Rough Milling cost model logic was updated in various ways to better approximate the tool types, tool sizes and tool engagements that would be used in practice to remove material from volumetric GCDs, and therefore produce more accurate cycle time estimates.

These Rough Milling cost model enhancements include:

-

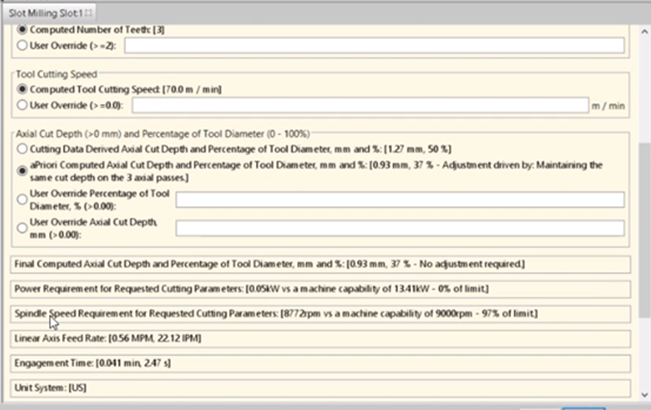

Cycle time estimates for rough milling of Pockets, Slots, Stock Trims, large Holes, and part Perimeters now are computed by determining the number of passes required, using a consistent axial depth of cut, to remove the material. Previously rough milling cycle times for these features were estimated using a volumetric material removal rate that could be overly agrresive. The previous removal rate was calculated based on GCD and tool dimensions, but could overestimate the removal rate that could be achieved on the final roughing pass depending on pocket depth and therefore underestimate feature time. As shown below, aPriori now provides a process setup option Axial Cut Depth and Percentage of Tool Diameter which displays both the nominal recommended axial cut depth (based on selected tool diameter and part material) and the adjusted cut depth which results in a consistent cut depth for all axial passes. The material removal rate is adjusted (reduced) correspondingly. This process setup option also allows the user to specify the desired axial cut depth either as a percentage of tool diameter or as a literal depth value.

Figure: Axial cut depth

-

Improved determination of rough milling tool diameters for Pocket GCDs -- previously aPriori selected overly-large tools for some pockets, particularly "square" pockets which have similar width and length. aPriori now selects smaller-diameter tools for these pockets so there is sufficient travel distance to ramp down in the z (depth direction) while traversing the length of the pocket.

-

Ball End Mill tools now generally will be assigned only for finish machining operations, not Pocket roughing operations. Previously aPriori assigned Ball End Mill tools for roughing operations when the Pocket GCD had a curved floor or when any of the pocket walls were undercut. Now, consistent with general machining practice, aPriori will select flat bottom end mills for roughing operations and use ball end mills for surface finishing operations, such as Contour Milling or Filleting.

- The Cutting Efficiency assumptions used in Rough Milling cycle time estimates now are adjusted based on characteristics of the Pocket, Slot, or Hole GCD. Previously, aPriori applied a cut-efficiency factor of 67% for all Roughing Operations (for all GCD types), to account for the fact that sometimes the tool is cutting air not chips. Now aPriori will consider whether the GCD is enclosed or whether there are openings for the tool to run off, to better estimate the amount of non-chipmaking time and therefore total roughing cycle time. For fully enclosed GCDs, the tool cannot runoff the part so cut efficiency now is set to 100%. For GCDs that are not fully enclosed, we assume half the tool diameter will run-off the openings in order to clear swarf away from the cutting surface. For example, if a Slot is closed at both ends we will assume there is no non-chipmaking time. If it is open at 1 or both ends we will account for half the tool running off the GCD and cutting air each time it gets to the open sections.