aPriori 2022 R1 provides a variety of enhancements to make it easier and faster to use aPriori Professional:

- Specify Stock Form prior to costing a part

- Faster Initiation of Bulk Costing & Analysis

- Specify Material Selection Mode in Bulk Costing & Analysis Inputs file

- Allow Choice of JPEG or PNG image formats in aPriori Spreadsheet Reports

- Improved Responsiveness for Large Assemblies, Large GCD Collections, and Large Numbers of Scenarios

- "In Process" Indicators for Computationally Intensive Actions

- Costing Performance Improvements

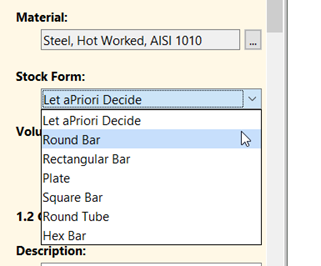

Specify Stock Form prior to costing a part

For the Stock Machining, Bar & Tube Fabrication, and Multi-Spindle Machining process groups, the Cost Guide and Bulk Costing interfaces now include a Stock Form field which allows users to specify the type of stock used for the part, prior to costing the part. This can reduce the number of costings and time required to get a complete manufacturing and cost analysis of the part.

In previous releases, aPriori determined the most likely stock form during the geometry extraction phase of the costing process, and users could review the chosen stock form and modify it only after the initial costing event was complete. This workflow proved inefficient particularly with complex parts that took a significant amount of time to cost, as users could wait several minutes to modify the stock form if they did not agree with aPriori's initial determination.

Users now can specify the stock form as a pre-costing input in several locations:

- In the Cost Guide, when interactively costing a part

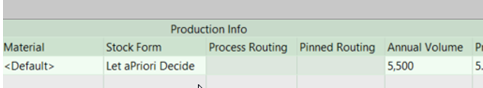

- In the Bulk Costing & Analysis user interface

- In the Bulk Costing & Analysis input spreadsheet

Figure: Stock Form field in the Bulk Costing Analysis user interface

Figure: Production info

Note: Stock Form is an optional input. If not specified, aPriori automatically will select a Stock Form, as in previous releases.

Additionally, like other production inputs, Stock Form can be mapped to a CAD property if desired. This enables customers who have implemented model-based definition (MBD) initiatives to define manufacturing information as attributes in the CAD file and facilitate automated workflows in which the desired inputs to aPriori are simply read from the CAD file and require little to no downstream manual corrections.

Limitation

In Cost Insight Design, Stock Form is not yet available as a pre-costing input. It is planned for a future release.

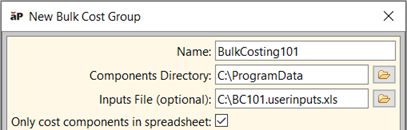

Faster Initiation of Bulk Costing & Analysis

aPriori 2022 R1 reduces the time it takes to setup and initiate a bulk costing of a subset of the parts contained in the designated components directory.

As in previous releases, aPriori provides the ability to bulk cost a set of parts and supply an Inputs File, or spreadsheet containing a list of part names and costing inputs. The New Bulk Cost Group dialog also provides an option to Only cost components in spreadsheet, as shown below.

Figure: New Bulk Cost Group

Prior to aPriori 2022 R1, when this was option was selected, aPriori first indexed all the CAD files in the specified Components Directory and built a bulk costing table containing an entry for each file, before finally ignoring the CAD files that were not included in the Inputs spreadsheet. For directories containing hundreds or thousands of parts, users could wait for several minutes for this pre-processing to complete so they could initiate the actual Bulk Costing event -- even if the Inputs spreadsheet referenced only a small number of parts. Now aPriori no longer will index parts that are not included in the Inputs spreadsheet, resulting in much shorter wait times to initiate bulk costing of a small subset of parts within a large directory.

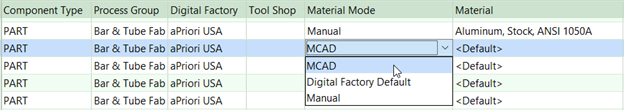

Specify Material Selection Mode in Bulk Costing & Analysis Inputs file

Material Selection Mode now can be specified for Bulk Costing & Analysis runs, better supporting model-based-definition (MBD) workflows by enabling Material defined in the CAD file to be applied when first costing or updating scenarios.

aPriori 2022 R1 allows users to specify the material selection mode when Bulk Costing, as shown below. Prior to this release, the material selection mode was accessible only in the main aPriori user interface. The material selection policy supports three modes: MCAD, Digital Factory Default, or Manual.

When the mode is set to MCAD, aPriori uses the material defined in the CAD file (provided that the material name exists in the Digital Factory or is mapped to a corresponding material in the Digital Factory). When the mode is set to Digital Factory Default, aPriori uses the default material for the specified process group, ignoring any MCAD value. When the user selects a specific Material, the mode automatically is set to Manual.

In previous releases, when Bulk Costing and updating previously-cost scenarios, there was no way to indicate that aPriori now should use the MCAD value if either the Digital Factory Default value or a specific material name were applied previously. Now the user can specify the material selection mode as MCAD and aPriori will apply the material defined in the CAD file (again, provided that the material name exists in the Digital Factory or is mapped to a corresponding material in the Digital Factory).

Allow Choice of JPEG or PNG image formats in aPriori Spreadsheet Reports

Customers can configure reports to use JPEG images of a specified compression level instead of PNG images.

Per customer request, aPriori 2022 R1 allows for thumbnail images included in spreadsheet reports to be formatted as JPEG as an alternative to the previously supported format of PNG. Thumbnail images will continue to be exported as PNG files by default, but users can modify the spreadsheet report’s XML definition file to specify JPEG as the default image format. In addition, users can specify the compression level for JPEG images, when the default format is set to JPEG. These are specified using two new attributes imageFormat and jpegQuality, as shown in the snippet of a report definition file below:

<reports generateThumbnails="true" imageFormat="JPEG" jpegQuality="0.85"

For more information on this and other aspects of configuring spreadsheet reports, refer to the chapter Spreadsheet Reports in version 2022 R1 of the aPriori Professional User Guide.

Improved Responsiveness for Large Assemblies, Large GCD Collections, and Large Numbers of Scenarios

aPriori 2022 R1 greatly reduces processing delays that occurred when interactively working with assemblies with many sub components or sub component scenarios, or with large collections of GCDs.

Previously, when analyzing complex assemblies with hundreds or thousands of sub-components, there were processing delays when the user switched from one tab to another (e.g., from the Cost Summary tab to the Assembly Details tab). There also were processing delays when expanding large collections within the Geometric Cost Drivers table. In aPriori 2022 R1, the processing time has been optimized to greatly reduce the delays when interactively working with large assemblies.

aPriori 2022 R1 also has improved the performance when switching sub-component scenarios within an assembly. Prior to this release, when a user clicked on a sub-component scenario and selected Switch Scenario from the right-mouse popup menu, aPriori searched the database for all scenarios of the same component name and evaluated access control permissions for all returned scenarios. In some instances this could take many seconds as there may be thousands of scenarios, only some of which the user had permissions to access. In this release, aPriori limits the search to twenty (20) scenarios rather than all scenarios of the same component name and displays a maximum of eight (8) scenarios within the right-mouse popup menu. These limits can be configured in the apriori.properities file, using the new settings apriori.menu.switchScenarios.maxToSearch and apriori.menu.switchScenarios.maxToDisplay.

If the desired scenario initially is not displayed in the popup menu due to these limits, the user can click on the Search for Scenario option to locate any scenarios of that component to which he has appropriate access permissions. This menu option previously was named Show More.

"In Process" Indicators for Computationally Intensive Actions

aPriori 2022 R1 now displays feedback to the user when various computationally-intensive actions are in progress.

Previously, aPriori did not alert the user when the system was performing a computationally- intensive task. As a result users could mistakenly think the application was hanging or otherwise unresponsive. For example, prior to this release, when selecting a Digital Factory from the Cost Guide, there potentially could be a delay of several seconds before the Digital Factory Selection dialog was displayed. (This could happen for customers with large numbers of Digital Factories when first opening the application, since the digital factories had not yet been loaded into memory and cached). During the time the user waited after clicking on the button until the dialog appeared, there was no indication that aPriori was processing the user action.

Now in aPriori 2022 R1, a wait cursor appears in the form of a spinner element to indicate that aPriori is processing the user action. The most common user actions now display wait cursors. In some instances, the feedback to the user appears as a spinning wait cursor, in other instances the feedback to the user appears as a green progress bar. Wait cursors for less-commonly used actions will be added in future releases.

Costing Performance Improvements

aPriori 2022 R1 reduces the computational processing times for costing events compared to earlier versions of aPriori.

Prior to this release, the Cost Engine interrogated all lookup tables and all process setup options each time a CSL module was evaluated during a costing. This could happen thousands of times during a single costing event and resulted in slower performance as more computational resources were used.

In this release, the Cost Engine selectively loads only the lookup tables and PSOs required for each CSL module at the time of their evaluation. This has significantly reduced the computational overhead and resulted in performance improvements across all process groups. Improvements vary by process group and part complexity. Across our test set typical computational processing times decreased by approximately 5% to 30%. The greatest improvements in performance are found in cost models containing greater numbers of lookup tables and process setup options. Specifically, customers using Machining should expect to see the most noticeable performance improvements.