aPriori 2022 R1 SP1 provides improvements to required clamp force estimates and updated material cost estimates for injection molded parts. The required clamp force estimates result in better machine selection and more accurate overhead estimates. For more information, see:

-

Improved Clamping Force Estimates for Injection Molded Parts

-

More Accurate Consideration of Regrind Material Use in Material Cost Calculations

Improved Clamping Force Estimates for Injection Molded Parts

Realize better machine selection and more accurate estimates of machine overhead costs.

Previously, aPriori used a conservative approach to calculating cavity pressure. For some parts, this approach resulted in the overestimation of the required clamping force and therefore the selection of a larger, more expensive machine than is practically required.

The cavity pressure is calculated from various inputs including the nominal wall thickness of the part and the effective flow length that the melt must travel from the gating location to the extremities of the part. Previously aPriori estimated the flow length as equal to the part length regardless of how the process setup options Edge Gate Location and Number of Hot Drops were set. In reality, the actual flow length varies based on the number of gates and the locations of each gate.

aPriori now computes the flow length more mechanistically by considering the number and location of gates. aPriori has also changed the default behavior for gate locations. For single gate cold runner tools, by default the edge gate is now located halfway along the long side, rather than the short side, of the part. For single gate hot runner tools, by default a center gate, rather than an edge gate, is now used on the short side. Due to these changes, the estimated flow length is now typically less than the part length. This difference yields a lower estimation of required clamp force compared to the estimation from the previous release.

Additionally, aPriori provides several new process setup options that can be used, along with pre-existing options, to specify the number and layout of gates for both hot and cold runner tools. One pre-existing, now-removed process setup option has been replaced by the combination of two of the new options. The relevant process setup options are:

Existing options:

-

Gating Type for Cold Runner System – Choice of Edge (default) or Center; controlled by the cost model variable

defaultGatingType -

Edge Gate Location – Choice of Long (default) or Short; controlled by the cost model variable

defaultRunnerAttachmentSide

New options:

-

Gating Runner System – Choice of Cold Runner (default) or Hot Runner; controlled by the cost model variable

defaultRunnerSystem -

Minimum Number of Gates per Cavity – Set to 1 by default; controlled by the plant variable

defaultNumberOfGatesPerCavity -

Hot Drop Layout – Choice of Linear (default) or Square; controlled by the cost model variable

defaultHotDropLayout -

Hot Drop Type - Choice of Standard (default) or SVG; controlled by the cost model variable

defaultHotDropType

Removed option:

The Number of Hot Drops per Cavity process setup option is no longer is available because it has been replaced by the new Gating Runner System and Minimum Number of Gates per Cavity options.

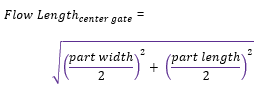

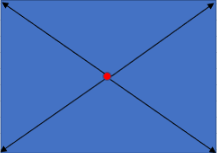

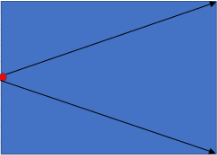

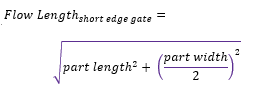

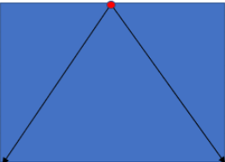

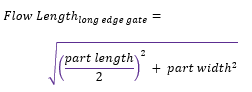

This table includes diagrams and equations that show how the melt flow length is now computed for a sample of gating schemes that involve different numbers of gates and gate locations. The blue box represents the part, the red circle indicates a gate location, and the black arrow represents the maximum flow length. See the Cost Model Guide for more information.

| Scheme | Diagram | Equations |

|---|---|---|

| Center Gate |

|

|

|

Gate on Short Edge |

|

|

| Gate on Long Edge |

|

|

As a result of this enhancement, the estimated Material Flow Length, and therefore Required Clamp Force estimates will change compared to the previous release of aPriori. The amount and direction of change depends on part aspect ratios and gating options.

In general, Flow lengths and Clamp Force will decrease for most parts. When a decrease occurs, a smaller machine with a lower overhead rate may be selected for the same part, and overhead costs will decrease.

However, for parts that are nearly square or that use short-side edge gates, Flow Lengths and Clamp Force may increase, resulting in the selection of a larger machine with higher overhead costs.

This table shows the average changes that were observed compared to the results from the previous release for a set of test parts that are processed by using cold-runner tooling. A similar impact is expected for parts that are processed by using hot runner tools.

| Number of Gates | Average Percentage Change Compared to Prior Release | |||

|---|---|---|---|---|

|

Required Clamp Force (kN) |

Machine Overhead Rate ($/hr) |

Machine Overhead Rate Cost ($) |

Fully Burdened Cost ($) |

|

|

1 (default) |

-8.0% |

-5.8% |

-6.5% |

-9.6% |

|

2 |

-16.2% |

-11.7% |

-12.3% |

-10.8% |

|

3 |

-18.3% |

-14.7% |

-15.3% |

-10.9% |

|

4 |

-19.2% |

-16.3% |

-17.4% |

-16.4% |

More Accurate Consideration of Regrind Material Use in Material Cost Calculations

Obtain more accurate Material Cost estimates for Plastic Molding, Assembly Molding, and Assembly Plastic Molding processes that include the use of regrind material.

Previously, Material Cost was not sufficiently reduced to account for the full amount of material assumed to be regrind, which is controlled by cost model variable defaultRegrindAllowance (0.25 by default). This calculation was updated to fully consider the specified amount of regrind material.

As a result of this fix, Material Cost will decrease compared to the previous release. The amount of decrease depends on part geometry, number of cavities and cavity layout, and the specified regrind percentage. In a set of test parts, Material Cost decreased on average by between 0.1% and 15.3%, with an average of 7.5%, as the specified regrind percentage was varied between 5% and 25%.