aPriori Professional 2022 R1 SP1 provides these enhancements for the Sheet Metal process group:

Support for Gusseted Bend Brakes

Cost bends that have gusset features

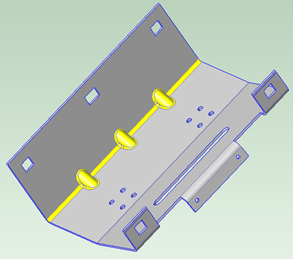

In prior releases, bend Geometric Cost Drivers (GCDs) that included gusset features failed to cost. For this release, the Bend Brake manufacturing process model has been enhanced to estimate the cost of making gusset features. aP Pro now assigns a Bending operation and estimates the cycle time and cost for making a StraightBend with gussets that are similar to those that are highlighted in this figure.

Figure: StraightBend with gusset features.

By default, aP Pro assumes that the gussets are formed simultaneously with the bend feature as controlled by the cost model variable defaultGussetStrategy. However, you can indicate that the gussets are formed after the bend feature, and whether multiple gussets are formed simultaneously or individually by using the Define When Gussets Can Be Formed process setup option. Additional cycle time is assessed for gussets made subsequent to the bend feature.

Note: aP Pro does NOT estimate any additional tooling cost for making gusset features.

Improved Length Measurement Algorithm for Bend Flaps

Obtain more accurate bending feasibility, design for manufacturability, and cost assessments for bends.

Two important properties in the analysis of bend flaps are:

-

Bend Flap Size(BendFlapSize) – The length of the flap of material that is adjacent to a Bend feature plus the arc length of the bend itself. -

Min Bend Flap Size(MinBendFlap– The minimum length of just the adjacent flap.

In previous releases, aP Pro used the three-dimensional model to measure the lengths that determine the values for these properties. Now aP Pro computes the values more accurately by using a flattened pattern of the part to take the length measurements.

Because of this change, the values for the parameters may change for many StraightBend GCDs. For most bends, the value changes by less than 10%, but larger changes can occur. The values may either decrease or increase, with decreases being more common. Accordingly, aP Pro now may make a different bending feasibility determination for a given bend, or provide different Design to Cost feedback, compared to the previous release. A bend that previously was assigned a bending operation now could fail if the updated Bend Flap Size measurement now falls below a recommended minimum threshold. The converse also is true: a bend that previously failed because the Bend Flap Size was below the threshold now may successfully be assigned a bending operation if the updated Bend Flap Size measurement now exceeds that threshold.

To retain the previous method of measuring BendFlapSize, set the process group site variable flattenBendFlapSize to false.

Improved Geometric Analysis for Complex Holes

Obtain more accurate cutting feasibility and cycle time results for complex holes, especially for narrow holes.

Several geometric properties of ComplexHole Geometric Cost Driver (GCD), including Area, Perimeter, and Mec Diameter (the diameter of the Maximum Enclosed Circle – the largest circle that can be inscribed inside the ComplexHole), are now computed more accurately. Due to the improved geometric analysis:

-

Area and Perimeter values will change very slightly compared to previous releases of aP Pro. Therefore, the cutting time for a specific hole may also change very slightly (by less than 1%, in a set of test parts).

-

Mec Diameter values may decrease more significantly, compared to the previous release of aP Pro which overestimated the value as the width of the smallest rectangle that could fit around the complex hole. If the calculated kerf width for the cutting process and material thickness is larger than the updated Mec Diameter value – meaning the kerf width is wider than the hole. Due to the updated calculation, a narrow ComplexHole that was assigned successfully in an earlier release may now be determined infeasible to manufacture with a 2D cutting process.

Theoretically, for a sufficiently narrow hole, this difference could occur for any ComplexHole and 2D cutting process, in both the Sheet Metal and Sheet Metal - Hydroforming process group. However, in practice only thick-gauge parts that contain relatively narrow cutouts that require OxyFuel or Plasma cutting processes, are affected. In a large test set, less than 1% of parts had a ComplexHole that was assigned a Machining operation because it was no longer considered feasible for a 2D cutting process.

Improved Depth Measurement Algorithm for Stamped and Formed Parts and Amended Operation Assignment for Forms

Obtain more accurate machine selection, overhead costs, and cycle time for stamped and formed sheet metal parts.

aP Pro 2022 R1 SP1 uses an improved algorithm for measuring the depth of formed features (Form GCDs) on stamped and formed sheet metal parts. Relative to prior releases, the new algorithm can affect machine selection, overhead costs, and, but to a lesser extent, cycle time. This release of aP Pro also corrects an error in prior releases that caused a form to be assigned to a Bending operation when it should be assigned to a Drawing operation.

Due to these updates, the estimated form depth for specific Form GCDs may change, compared to a previous release of aP Pro. This measurement change can affect machine selection, because the machine shut height must be large enough to accommodate the deepest form on the part. If a different machine is selected, estimates for the overhead costs, and to a lesser extent cycle time, can be affected.

In a set of test parts, decreases in form depth were more common than increases. For the majority of test parts, form depth values changed by less than 20%, but a significant minority had changes of greater than 20%. However, in the test set, there was only minor impact on machine selection. In some cases, a smaller, less-expensive machine was chosen than in the previous release of aP Pro.