Digital Factory Enhancements

Linking Custom Materials to Source Materials

You can link a custom material to another material to automatically inherit both initial values and value updates for the custom material.

Previously, when you added a new custom material to your Digital Factory, you had to manually enter all the data for that material. If the cost of the material later changed, you also had to manually update the cost.

Now, if you link a source material to a new or preexisting custom material, the custom material inherits, via reference, the current value and, by default, any future value updates from the corresponding fields in the source material.

For example, suppose you want to add a new custom ABS plastic to the Plastic Molding group in your Digital Factory. Also suppose that, except for the density, you want all the values for the custom plastic to match a baseline ABS plastic. When you add the new custom plastic, link to the baseline ABS plastic so that you can inherit values and value updates. Then, edit only the density for the custom plastic. If the unit cost for the baseline ABS is later updated to a new value, the price for your custom plastic updates to the same new value. However, editing the density value brakes the link to the baseline density field. Therefore, even if the density in the baseline changes due for example to a material processing change, the density in your custom material will not change.

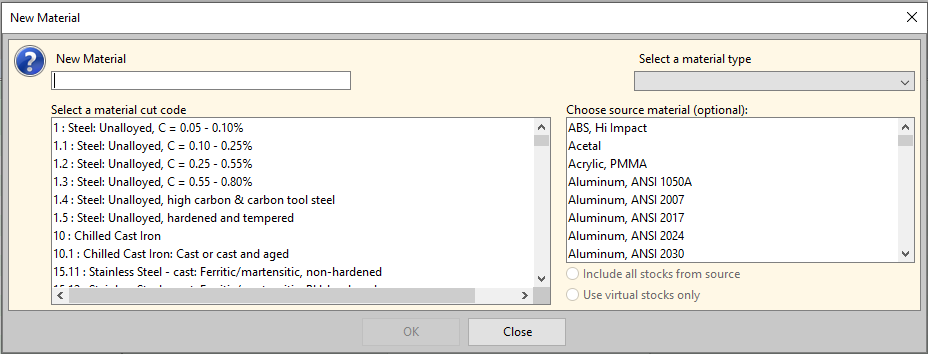

You can select either a baseline or a different custom material for the source material. The source material that you select must be the same type of material as the custom material that references it.

By default, when you link a custom material to a source material, every field in the custom material is linked to, and therefore references, the corresponding field in the source material. To override a referenced value or to stop inheriting future value updates, you can unlink any two linked fields.

If you select the source material when you add a new custom material, you benefit by not having to enter manually any values that are the same for the custom and source materials. While you are adding the new material, you can either reference or override the cut code value from the source material. If you select a source material that comes in a variety of stock sizes, then by default, the stock items for the source material are replicated for the new material. If you prefer, you can select the option to Use virtual stocks only for the new material.

If, for the source material, you select a baseline material or a custom material that directly or indirectly references a baseline material, then you benefit by not having to enter manually any referenced values that are updated in the baseline material when the Regional Data Libraries are updated.

Additional enhancements in aPriori Professional 2023 R1 enable you to:

-

Select a source material from a different process group. For more information see Generic Materials for Material Linking.

-

Adjust the value of the unit cost in a custom material that is linked to another material by using a custom unit cost factor. For more information, see Adjustment Factors for Linked Material Values.

To learn how to use these enhancements, see:

-

Adding a custom material (aPriori Professional Factory Administration Guide)

-

Working with linked materials (aPriori Professional Factory Administration Guide)

-

Using adjustment factors for linked materials (aPriori Professional Factory Administration Guide)

Generic Materials for Material Linking

Link to fields in a material that is not included in the Materials table for the current process group.

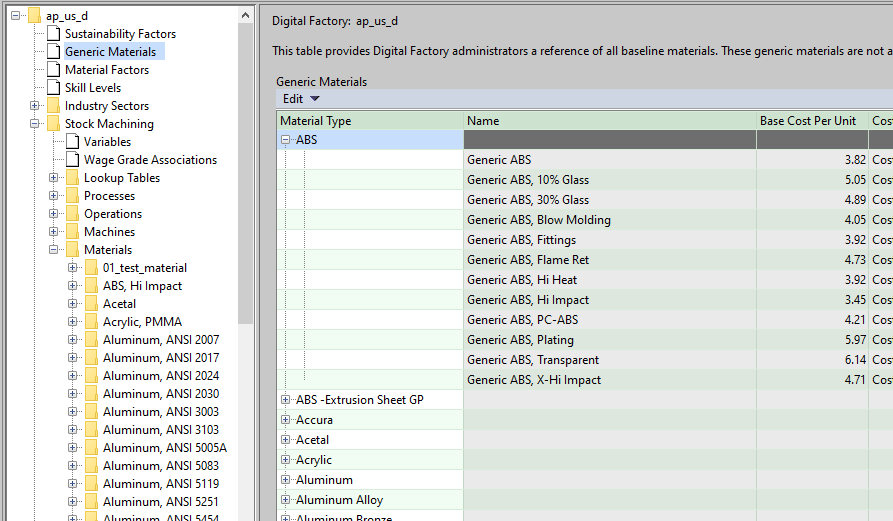

In addition to introducing Linking Custom Materials to Source Materials, aPriori Professional2023 R1, includes generic materials that you can link to if no material from the current process group is suitable for referencing for your custom material.

For example, suppose you want to add a new custom ABS plastic to the Stock Machining group in your Digital Factory. Also suppose that you want to link the new custom plastic to a baseline ABS plastic so that you can inherit values and value updates. You can do so, even though, by default, there is no ABS material in the Stock Machining Process group by linking to a generic ABS type plastic.

The Generic Materials table now is included in all Digital Factories and serves as a comprehensive and consolidated list of all materials provided across all process groups in the aPriori Regional Data libraries. The materials in the table are available to select when you link to a custom material to a source material.

The values for Generic materials are as generic as possible. If a material is in multiple process groups, and it has a field whose value varies across process groups, the generic version of that material contains the value that occurs most frequently for that field.

Note: The value for the Carbon Emission Factor is intentionally null for Generic Materials because the value of Carbon Emission Factor is highly specific to the process group and to how the material is processed and sourced.

To learn how to use these enhancements, see:

-

Adding a custom material (aPriori Professional Factory Administration Guide)

-

Working with linked materials (aPriori Professional Factory Administration Guide)

-

Using generic source materials (aPriori Professional Factory Administration Guide)

Adjustment Factors for Linked Material Values

Apply an adjustment factor to updates to custom material values that reference baseline material values.

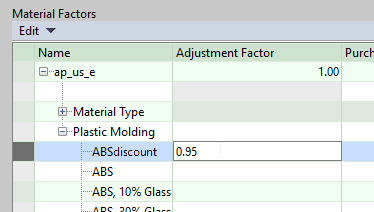

In addition to introducing Linking Custom Materials to Source Materials, aPriori Professional2023 R1, enables you define and apply an adjustment factor for custom material values that reference source material values. Adjustment factors can be applied at either the material level (for a single custom material that references a baseline material) or at the process group level (for all custom materials in the process group that references a baseline material).

For example, suppose you want to add a new custom ABS plastic to the Plastic Molding process group in your Digital Factory. Also suppose that, except for the cost, you want all the values for the custom plastic to match a baseline ABS plastic. The cost of the custom material is 5% less than the cost for the baseline ABS plastic because you negotiated a discount that tracks with the market cost. When you add the new custom plastic, link to the baseline ABS plastic so that you can inherit values and value updates. Then, update the Adjustment Factor field for the custom material in the Material Factors table. The factor for a 5% discount is 0.95 because the value for the custom material is the product of the adjustment factor and the referenced value.

Then, when the cost for the baseline ABS updates in response to a Regional Data Libraries update, the cost for the custom plastic will also update, but it will continue to be 5% less than the baseline cost.

If you get the same type of discount for all the custom materials in the Plastic Molding process group, instead, apply the factor to the process group. Then, when the cost for the referenced baseline materials update in response to a Regional Data Libraries update, the cost for the custom materials that reference them will all also update, but will continue to be 5% less than the baseline costs.

To learn how to use these enhancements, see:

-

Adding a custom material (aPriori Professional Factory Administration Guide)

-

Working with linked materials (aPriori Professional Factory Administration Guide)

-

Using adjustment factors for linked materials (aPriori Professional Factory Administration Guide)