Casting Enhancements

aPriori 2024 R1 provides a set of related enhancements which result in significant improvements in the extraction and display of Void and ComboVoid GCDs. These GCDs represent undercut and recessed geometry in the part. aPriori uses these GCDs and their properties to determine tooling approach and tooling cost for cast parts. These enhancements affect a number of process groups: Casting – Sand, Casting – Investment, Casting – Die, Forging, and Powder Metal.

The key areas of enhancement are as follows:

- Improved Estimates for Recessed (“Breakaway”) Voids

- Improved Manufacturing Operation Assignment for Child Voids (Sand Casting)

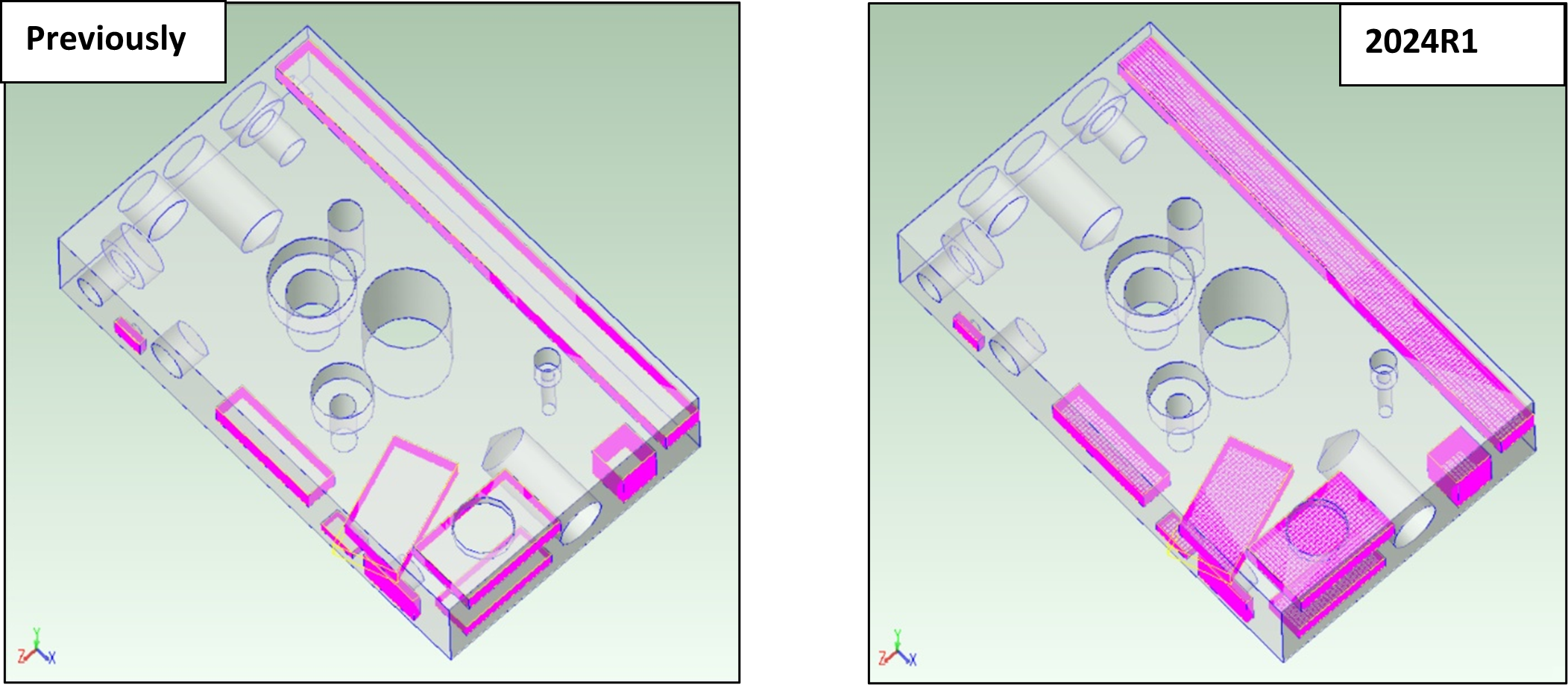

Improved Display of Void GCDs

aPriori now more clearly displays Void and ComboVoid GCDs in the Viewer window.

Previously aPriori highlighted only the walls of voids, sometimes making it difficult to understand the volume they represented. Additionally, the cylindrical walls of holes included in a ComboVoid were displayed in yellow, while other walls were displayed in purple. Now aPriori highlights the full volume of voids and combo voids and consistently uses the color purple. This greatly improves the user’s ability to visualize and understand the extent of the void. A simple example of the improvement is shown below.

Note: You must recost scenarios saved in a prior release in order to see the improved 3D display of voids.

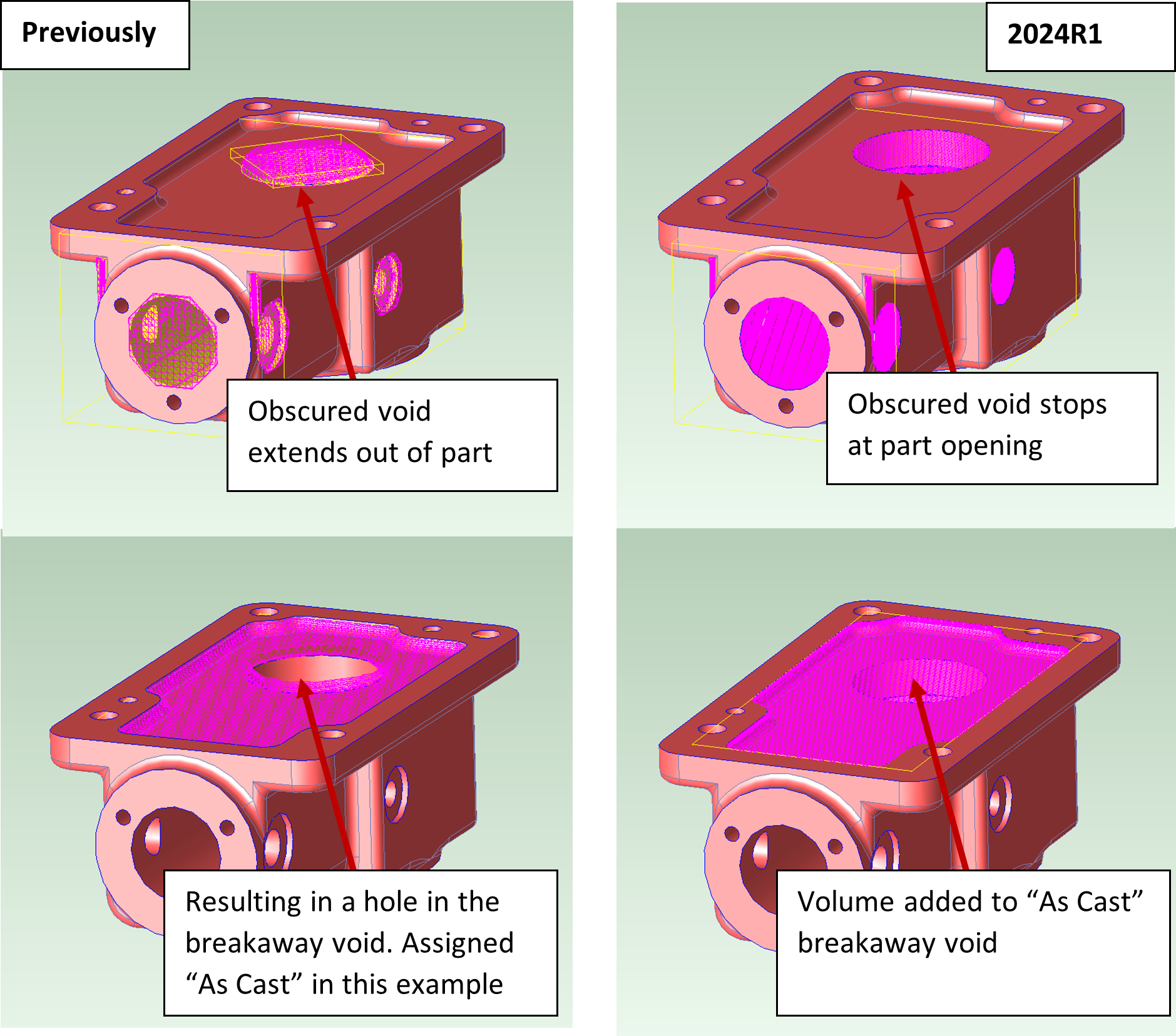

Improved Estimates for Recessed (“Breakaway”) Voids

In the Casting - Sand, Casting - Investment, Forging, and Powder Metal process groups, aPriori 2024 R1 leverages a new algorithm which better determines the size, shape, and manufacturing method for a recessed feature, including whether it should be grouped with other cavities and recessed features to make a single larger core tool.

In aPriori there are two types of Void GCDs: obscured voids, which are cavities that are not accessible from the draw direction, and "breakaway" voids, which are external recesses that are accessible from the draw direction. Previously, aPriori’s geometry engine used a ray-based algorithm to detect obscured voids, and a less-accurate voxel-based algorithm to detect breakaway voids. The following process groups extract breakaway voids: Casting - Sand, Casting - Investment, Forging, and Powder Metal.

In aPriori 2024 R1, breakaway voids now are extracted using a ray-based algorithm. This new algorithm results in more accurate and more credible Void GCD extraction, which in turn results in more accurate manufacturing operation assignment and tooling estimates.

Note: The new site variable breakawayVoidAlgorithm (set to Ray-Based by default) allows customers to revert to the previous algorithm to avoid changes in GCD extraction (by setting the value to Voxel-Based).

Some details of the improvements are described below:

-

The calculated Volume of the Void GCDs is more accurate and will not be as heavily influenced by a user changing draw direction. Previously, changing draw direction sometimes could result in significant changes to computed Void dimensions, when it caused a different algorithm to be used due to the void accessibility from that direction.

-

Breakaway voids previously excluded the volume of enclosed or adjacent rotationally-symmetric features (for example, Holes, MultistepHoles, Rings, or RingedHoles.) Moreover, sometimes these excluded features were assigned to a machining operation instead of a more appropriate coring or “As Cast” operation. Now these features will be included in the void and will be assigned casting/coring operations as appropriate. A simple example is shown below :

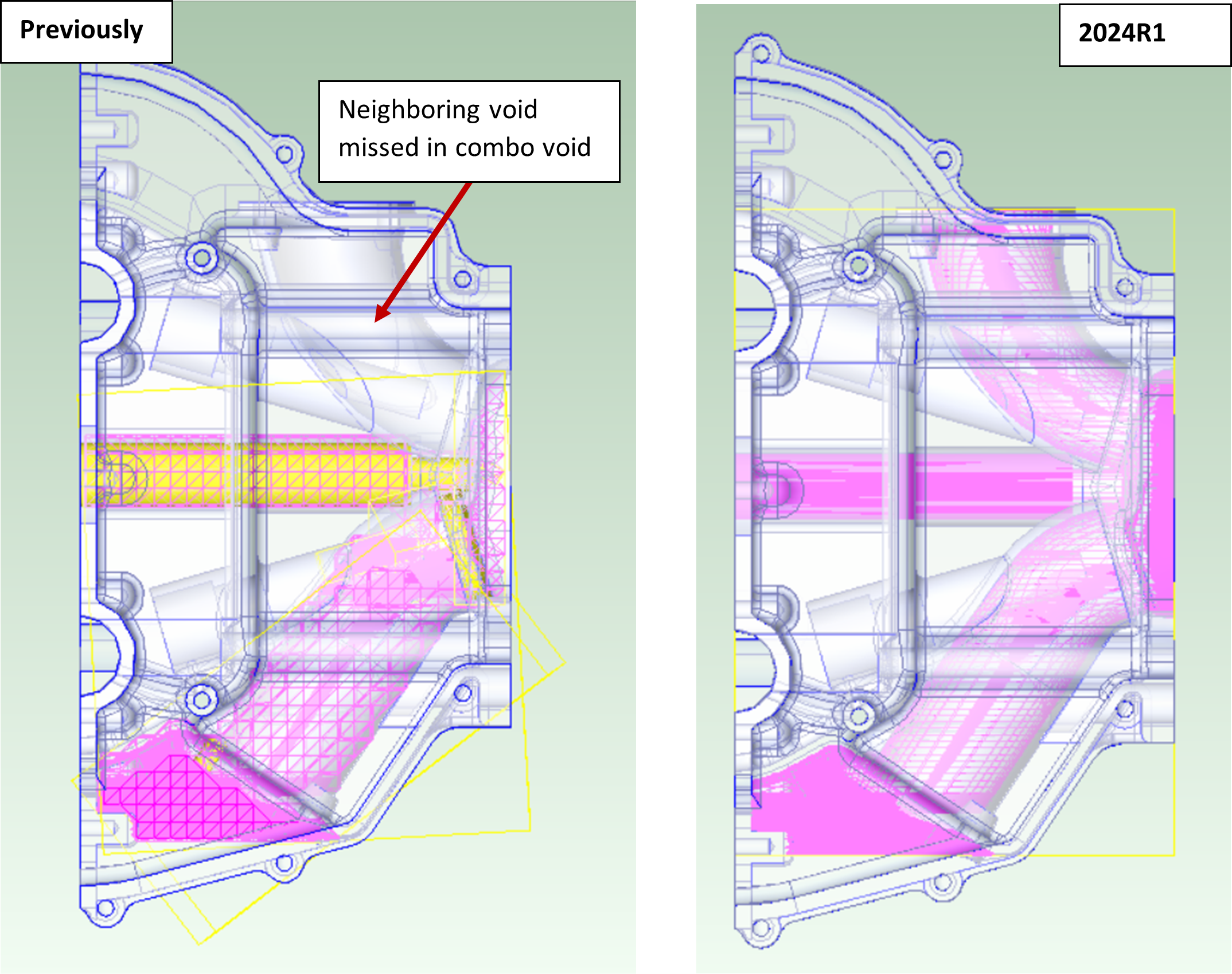

-

ComboVoid GCDs are made up of a group of adjacent Void and Hole GCDs, and they represent a combined volume that can be made with a single core tool. The new algorithm provides better detection of void openings and neighboring voids, resulting in more robust merging of breakaway voids with obscured voids to make a ComboVoid. Previously aPriori was more likely to create separate GCDs instead of merging into a single ComboVoid. The following screenshots show improvements in the merging of a ComboVoids:

-

The new ray-based algorithm better detects small or shallow voids, that sometimes were not recognized by the old voxel-based algorithm. The new algorithm also better detects the presence of thin walls on a model, ensuring that voids on the outside of the part are not merged incorrectly with voids on the inside of the part.

-

The ray-based algorithm was enhanced to more accurately determine the number of openings a void has to the outside of the part, which is an input into decisions regarding whether the void should be merged into a ComboVoid and what types of manufacturing operations are feasible. This enhancement applies to obscured voids as well as breakaway voids.

Improved Manufacturing Operation Assignment for Child Voids (Sand Casting)

aPriori 2024 R1 corrects a bug in which voids which could be cored in practice instead were assigned a machining operation.

aPriori 2024 R1 fixes an issue in which some child Voids of ComboVoids that could in fact be cored instead were assigned a machining operation. This occurred for child Voids which do not have a direct opening to the outside of the part but are connected to an adjacent Void which would allow the sand core to be removed during shakeout. Due to this fix, cost estimates may decrease significantly compared to the previous release. The maximum change seen in a suite of parts was an 11% decrease in fully- burdened cost.