These issues, which were discovered in prior releases, are resolved in aP Pro 2024 R1:

-

Casting - Sand – In aPriori 2024 R1, the Special Mold Tooling section of the Design Guidance tab now displays an accurate count of cores for Casting – Sand parts. Previously, the guidance may have displayed an incorrect number of cores. Note that this was a display issue only and cost estimates used the correct number of cores.

-

Reading Material from CAD File – aPriori 2024 R1 corrects a CAD material mapping issue introduced in the aPriori 2023 R1 release stream. This issue potentially affected customers who use a material specified in the CAD file to drive material selection in aPriori. Due to this issue, when re-costing a previously saved scenario, aPriori in some cases selected the process group default material instead of the material specified in the CAD file. In aPriori 2024 R1, the intended material will be selected when aPriori re-costs these older scenarios. Note this issue affected only scenarios created prior to aPriori 2023 R1, not new scenarios created in aPriori 2023 R1 or later.

-

Process Group Display in Part Cost Report – aPriori 2024 R1 resolves an issue introduced in aPriori 2023 R1 in which the Part Cost report may have displayed a secondary process group (for example, Surface Treatment) instead of the primary process group (for example, Stock Machining).

-

Machining: aPriori 2024 R1 corrects an issue in which the cycle time for side milling a surface erroneously was calculated as an extremely large number. This issue occurred only when the surface was the wall of a Slot that was assigned General Rough Milling and the wall was oriented 90 degrees to the primary setup axis.

-

Machining: aPriori 2024 R1 corrects an error in which Wire EDM Cutting failed if assigned to the central hole of a MultiStep Hole GCD. Now Wire EDM Cutting can be assigned to such holes and cost successfully.

-

Machining: aPriori 2024 R1 now allows Wire EDM to be assigned to machine slots which have yaw. Previously Wire EDM operations would fail for such slots, but this is feasible in practice so now is allowed.

-

Machining: aPriori 2024 R1 corrects an error that occurred for some castings and forgings with secondary machining on 4-Axis Mill. In some cases, an incorrect rotational setup direction was chosen for the part. Now the correct rotational setup will be selected.

-

Assembly Welding: aPriori 2024 R1 corrects an error in which Labor Handling Time and the associated cost for part loading, unloading, and re-orientation was over-estimated by a factor of two, for the following processes: Manual MIG Welding, Manual Spot Welding, Manual TIG Welding, Robotic MIG Welding, Robotic Spot Welding, Robotic TIG Welding.

-

Assembly: aPriori 2024 R1 corrects an error which caused the calculated Indirect Overhead Rate to be significantly too low for the following processes: Adhesive Bonding, Cap Sealing, Fay Sealing, Fillet Sealing, Lock Bolt, Rivet, and Threaded Insert. This error was due to a formatting error which led to populating various machine fields which that contribute to the overhead calculation (Machine Uptime Factor, Installation Factor, Annual Maintenance Factor, and Salvage Value Factor) as whole numbers instead of fractional percentages, and therefore the value was 100 times greater than intended (for example, a machine uptime of 80, instead of 0.8, to represent 80%). As a result of this fix, calculated Indirect Overhead Rate values for these processes will increase significantly (by a factor of ~100). Direct Overhead Rate values will increase very slightly.

Note that customers will need to install the 2024-03 RDLs and upgrade to the latest version (CMV) of the Assembly manufacturing process model and to receive the full fix. If you do not upgrade the Assembly model, then the overhead calculation will be corrected, but values still will display incorrectly (with a value 100 times greater than the correct fractional representation).

-

Hydrostatic Leak Testing Failing for 2-Model Machining and Assemblies: aPriori 2024 R1 corrects an issue in which costing would fail if the secondary process Hydrostatic Leak Testing was included in a 2-Model Machining scenario or any Assembly scenario (including Assembly Molding and Assembly Plastic Molding). Note that for Assembly process groups, the costing still will fail unless a thickness value is supplied to the Hydrostatic Leak Testing process. This value can be supplied either by first costing child components of the assembly, or by using the process setup option Average Wall thickness.

-

GCD Extraction Triggered Based on Specific User Overrides: There are a number of workflows and user overrides in aPriori that require GCDs to be re-extracted when a manufacturing simulation is executed. In the previous release we found two areas of the aP Pro UI where end users could make changes that incorrectly allowed the next simulation event to run without GCD re-extraction: when users removed overrides from the Cost Override Summary and when users edited property values in the table view of the Geometric Cost Drivers pane.

In the Cost Override Summary, users have the ability to remove overrides and re-cost. Some of the overrides that can be removed require GCDs to be re-extracted. For example, removing a user override to the selected draw direction should result in aPriori recomputing the draw direction. Previously this functionality was not working, resulting in new simulation events skipping the GCD re-extraction. In 2024 R1, aPriori has fixed this issue and GCDs will be extracted when an override is removed that affects GCD extraction.

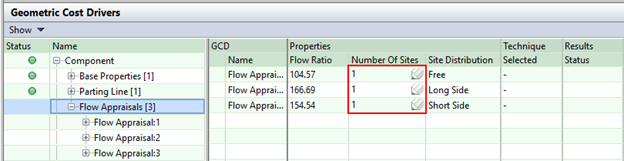

In the Geometric Cost Drivers pane, a number of GCD properties are editable in the UI, and a subset of these editable properties will force GCD re-extraction if changed. For example, in Plastic Molding, if a user updates the Number of Sites property of a Flow Appraisal GCD, this will force GCD re-extraction when the next manufacturing simulation is run. Previously, if a user edited a GCD property from the table view and reran a simulation, aPriori incorrectly skipped GCD extraction. In this release, this issue has been resolved and edits made in the GCD table will be respected, forcing GCD re-extraction when necessary.

Note that the table view appears when you click the parent node of individual GCD nodes in the GCD tree, for example, when you click the node labeled SimpleHole[10] in the Geometric Cost Drivers Pane shown below:

-

Resolved Diameter Tolerance Extraction from NX Hole and Thread Callout: For NX CAD models, aPriori now reads Diameter Tolerances specified by the Hole and Thread Callout feature. NX introduced a new Hole and Thread Callout feature in NX1926, which allows users to specify PMI for holes in the model, including adding diametrical tolerances. Previously aPriori did not extract diametrical tolerances defined using this NX feature.

Note: Due to a known issue, PMI is not read for some holes that have been modeled using the pattern feature. If you encounter this issue, please report it to aPriori Support.

-

Creo Direct Integration PMI Missed for First Surface: aPriori 2024 R1 corrects an issue reading GD&T tolerances applied to multiple surfaces, which occurred only for customers using aPriori on-premise with Creo 8, Creo 9, or Creo 10 in Direct Integration mode. In previous releases, aPriori neglected to import the tolerance for the first surface referenced by the tolerance annotation in the CAD model. For example, if a Flatness tolerance was added to three surfaces, aPriori did not apply the tolerance value to the first surface, and applied it to only the second and third surface. This issue was caused by a change in the Creo Toolkit APIs and now is corrected.

-

Improvements to Sheet Metal Blank Outlines with Addendum: For aPriori Sheet Metal process groups, the blank can include an “addendum” which is an extra width of material added to (offset from) the outline of the flattened finished part. This addendum accounts for extra material required to form the part or hold it during forming. In rare cases, the addendum erroneously included large “spikes” in the adjusted blank outline, which were not required in practice and adversely affected part nesting and utilization estimates. In this release, aPriori has introduced a new algorithm for generating the addendum to address this issue. For parts affected by the original issue, users will observe a smoother, more reasonable blank outline and higher estimates of material utilization.