PCB Fabrication Enhancements

In aP Pro 2024 R1, the PCB cost model includes multiple enhancements:

-

Dip Tank Processes Updated to be More Mechanistic and Accurate

-

Improved Interpretation of Specific ECAD Gerber File Formats

Dip Tank Processes Updated to be More Mechanistic and Accurate

The PCB cycle time calculation was updated for all dip tank processes, resulting in significantly reduced estimates of cycle time and fully-burdened cost.

In aPriori 2024 R1, the PCB Fabrication manufacturing process model structure and cycle time logic have been updated for all dip tank processes: Desmear, Plate Through Holes, Copper Plate, Tin Coat, and Electroless Nickel Immersion Gold.

One update is to the structure of the model. Previously, the dip tank processes listed above were modeled as distinct and independent processes. In reality, these processes are completed in sequence on the same machine. Therefore, in this release, Desmear and Plate Through Holes are combined into a single process and Copper Plate and Tin Coat are combined into a single process, to better represent a single machine performing two processes at one time.

Another update is to the cycle time calculation for dip tank processes. Previously, aPriori conservatively calculated cycle time based on the time to pass the board through all the required dip tank operations. For example, the cycle time for Copper Plate included the pre-treatment time, plating time, and post-treatment time. This calculation incorrectly assumed that a single rack of panels is processed by the machine at any one time. In reality, the machine processes multiple racks of panels at any one time, with bottleneck process steps dictating the throughput capability of the machine. In this release, the cycle time logic is updated to consider both the elapsed time required to complete the bottleneck process step and the number of dip tanks or cells a machine has allocated to the bottleneck process step and therefore the number of panels that are processed in parallel. This change results in a significant reduction in estimates of cycle time and fully burdened cost, with an average fully-burdened cost decrease of 44% across the aPriori test suite. Please see the 2014 R1 Upgrade Impact Guide for more detail.

A more detailed summary of the changes for each of the listed processes is as follows:

-

A new combined process, "Desmear and Plate Through Holes", replaces the separate processes "Desmear" and "Plate Through Holes". Some details of this new process are described below:

-

It uses the same machines previously available for the Copper Plate and Electroless Nickel Immersion Gold processes. These machines can be used for any dip tank process, hence we have standardized the list of machines.

-

The bottleneck operation is Electroless Through Hole Copper Plating. The cycle time for the plating is driven by the existing cost model variable electrolessThroughHoleCopperPlateTime .

-

The machine property Number of Gating Tanks specifies the number of tanks that will be used in parallel for the bottleneck operation. The machines have Usable Tank Width, Usable Tank Depth, and Usable Tank Length properties which are used to calculate the number of panels that can fit within each tank.

-

The machine selection logic has been updated to select the cheapest machine by considering the amortized direct overhead rate (direct overhead rate divided by the number of panels that fit on the machine). This is new logic that did not exist in the old processes. In the previous version of the manufacturing process model, aPriori selected the smallest machine with the lowest overhead rate that could fit a single panel, which could in some cases be more expensive than using a larger, higher-rate machine that can accommodate multiple panels.

-

-

A new combined process, "Copper Plate and Tin Coat", replaces the separate processes "Copper Plate" and "Tin Coat". Some details of this new process are described below:

-

It uses the same machines previously available for the Copper Plate process, again standardizing the machine list.

-

The bottleneck operation is Copper Plating. The cycle time for plating is calculated using the same logic as before, considering the plating thickness and plating rate.

-

The machine property Number of Gating Cells specifies the number of anode/cathode cells which will be used in parallel for the bottleneck processoperation. The machines have Usable Cell Width and Usable Cell Depth properties which are used to calculate the number of panels that can fit within each cell.

-

The machine selection logic was updated to select the cheapest machine by considering the amortized direct overhead rate (direct overhead rate divided by the number of panels that fit on the machine). This is new logic that did not exist in the old processes.

-

-

Electroless Nickel Immersion Gold remains a standalone process but includes updated logic. Some details of this updated process are described below:

-

The bottleneck operation is Electroless Nickle Plating. The cycle time for the plating is calculated with the same logic as before, using the existing cost model variable electrolessNickelTime.

-

The machines have new Limit properties to match the other dip tank processes. A new property, Number of Gating Tanks, specifies the number of tanks that will be used in parallel for the bottleneck operation. New properties for Usable Tank Width, Usable Tank Depth, and Usable Tank Length were added to the machines. These properties are used to calculate the number of panels that can fit within each tank. For Electroless Nickel Immersion Gold, the panels are placed on a rack that is dipped into the tank; the panel spacing is controlled by two new cost model variables called dipTankPanelSpacingWidthwise and dipTankPanelSpacingLengthwise.

-

The machine selection logic was updated to select the cheapest machine by considering the amortized direct overhead rate (direct overhead rate divided by the number of panels that fit on the machine).

-

New Laser Drilling Process for Micro Vias

The PCB cost model was enhanced to include the laser drilling process for PCBs with micro vias that are too small to create with a mechanical drill. This addition enables aPriori to cost a wider range of PCBs, including HDI boards where laser drilling is common.

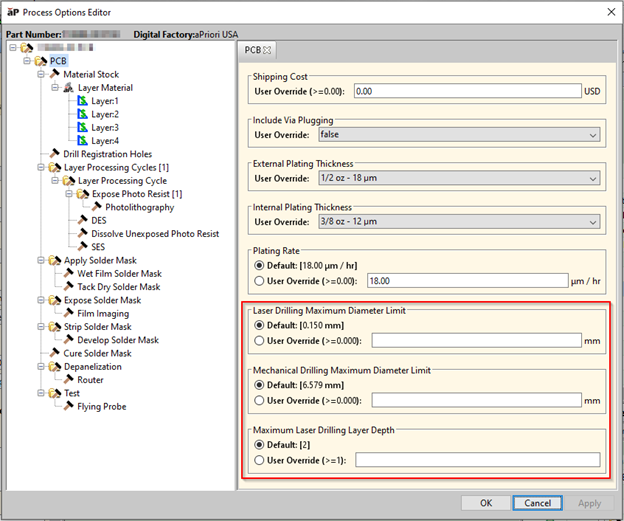

In aPriori 2024 R1, the PCB Process Group includes a Laser Drilling process with three new laser drilling machines. Laser Drilling cycle time is computed using a rate that is defined by the machine property Holes Per Minute. The rate can be overridden for a given scenario using the process setup option Holes Drilled per Minute. The laser drilling process assumes that a single laser pulse creates each hole.

aPriori will automatically assign laser drilling to holes that fall below two size thresholds:

-

Hole diameter is less than or equal to 0.15 mm (controlled by the new cost model variable viaDrillingUpperDiameterLimit)

-

Hole depth is less than or equal to 2 layers (controlled by the new cost model variable viaMaxDepthNumberOfLayers).

Both these thresholds can be overridden for a given part using the new process setup options Laser Drilling Maximum Diameter Limit and Maximum Laser Drilling Layer Depth on the PCB node.

aPriori supports the costing of stacked laser drilled vias only if they are defined as separate holes in the ECAD file. For example, if a stacked via passes between layer 1 and layer 4, aPriori requires the hole to be defined as three distinct holes (one hole between layers 1 and 2, one hole between layers 2 and 3, and one hole between layers 3 and 4). aPriori does not support stacked vias that are defined in the ECAD file as a single hole passing between multiple pairs of layers.

Known Limitation: If a PCB is costed and aPriori does not assign laser drilling to any of the common hole group GCDs due to the thresholds listed above, the end user will not be able to manually assign a common hole group to laser drilling. To work around this limitation, adjust the thresholds using the process setup options Laser Drilling Maximum Diameter Limit and Maximum Laser Drilling Layer Depth so that aPriori automatically assigns laser drilling to at least one common hole group. Once at least one common hole group is assigned to laser drilling, the user you can manually assign either laser or mechanical drilling to any of the common hole group GCDs.

Updated estimates of Mechanical Drilling Expendable Tooling

The PCB Fabrication process model provides more accurate estimates of mechanical drilling expendable tooling costs, by updating the material pricing and the re-usability of the materials.

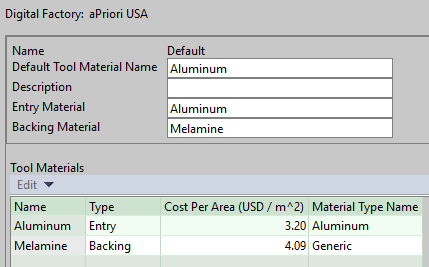

In mechanical drilling of PCB panels, there are protective plates used to guide the drill on entry and prevent burr on the exit of the drill. Previously aPriori assumed two four-dollar protective plates were used for every panel that was manufactured, regardless of size. In aPriori 2024 R1, expendable tooling cost estimates have been enhanced to account for the size and usage of the protective plate(s). Additionally, aPriori now distinguishes between two types of protective plates, an “Entry” protective plate and a “Backup” protective plate. The Entry plate is always required and is single use; the Backup plate is required only if there are through holes, and is double use (as it can be flipped over). The Mechanical Drilling toolshop now includes Cost Per Area data for both an Aluminum entry plate and a Melamine backing plate, so that the calculated cost for expendable tooling will vary depending on the size of the panel stock being drilled.

Due to this enhancement, expendable tooling costs for Mechanical Drilling will decrease significantly compared to the previous release. In a set of test parts, expendable tooling costs decreased by 83% and Fully Burdened Cost decreased by 32%.

Note: Ensure that the new toolshop data is present when you upgrade a configured digital factory to the latest cost model version; if it is missing, aPriori will fail to cost all PCBs.

Improved Interpretation of Specific ECAD Gerber File Formats

In aPriori 2024 R1, the PCB Fabrication process group improves interpretation of specific modeling practices in specific ECAD formats (holes/vias defined in Altium and CADSTAR Gerber files, and legend Gerber files from PADs).

This release includes the following improvements:

-

aPriori 2024 R1 can read .drr files exported in Altium Gerber Files. This file defines what layers the accompanying drill files pass through, which allows aPriori to determine if holes are buried, blind, or through holes. Previously, aPriori ignored this .drr file and all holes were considered as through holes. This enhancement will result in more accurate GCD extraction and in turn more accurate costing for boards with buried or blind vias.

-

For Gerber files exported from CADSTAR, aPriori maps the drill file to the report file (.rep) in order to determine the tool sizes for each hole. In this release, a new fallback has been introduced so that if only one report file is defined, it will be used to define the tool sizes for all drill files. Previously, boards with one report file that was not mapped to the drill file would have failed to extract holes/via GCDs.

-

The XSLT mapping for Gerber files exported from PADs was updated so that files with “legend” in the name are not incorrectly extracted as copper layers.

Note: To receive these enhancements, you must ensure that the latest XSLT script is uploaded during the aPriori upgrade to 2024 R1. For more information, see the section Import New aPrioriDefault.xsl File in the aP Pro Installation Guide.

Simpler Configuration for 12+ Layer Boards

The PCB fabrication CSL logic was updated to dynamically respond to customers expanding the layer configuration options defined in the Digital Factory lookup tables.

In the baseline PCB fabrication process model, aPriori supports costing PCBs with up to 12 layers. Additionally, the Digital Factory can be configured to cost boards with more than 12 layers. Previously, to configure this change, it was necessary to update two lookup tables (tblLayerMaterialType and tblDielectricthickness) and add additional CSL logic to respect the additional configurations added to the lookup tables. In aPriori 2024 R1, the customer no longer needs to update the CSL logic, as now the process model will automatically accommodate updates to the lookup tables. This simplifies the configuration and management of the Digital Factory.