Stock Machining Enhancements

Improved Side Milling Operation Assignment for Neighboring Surfaces

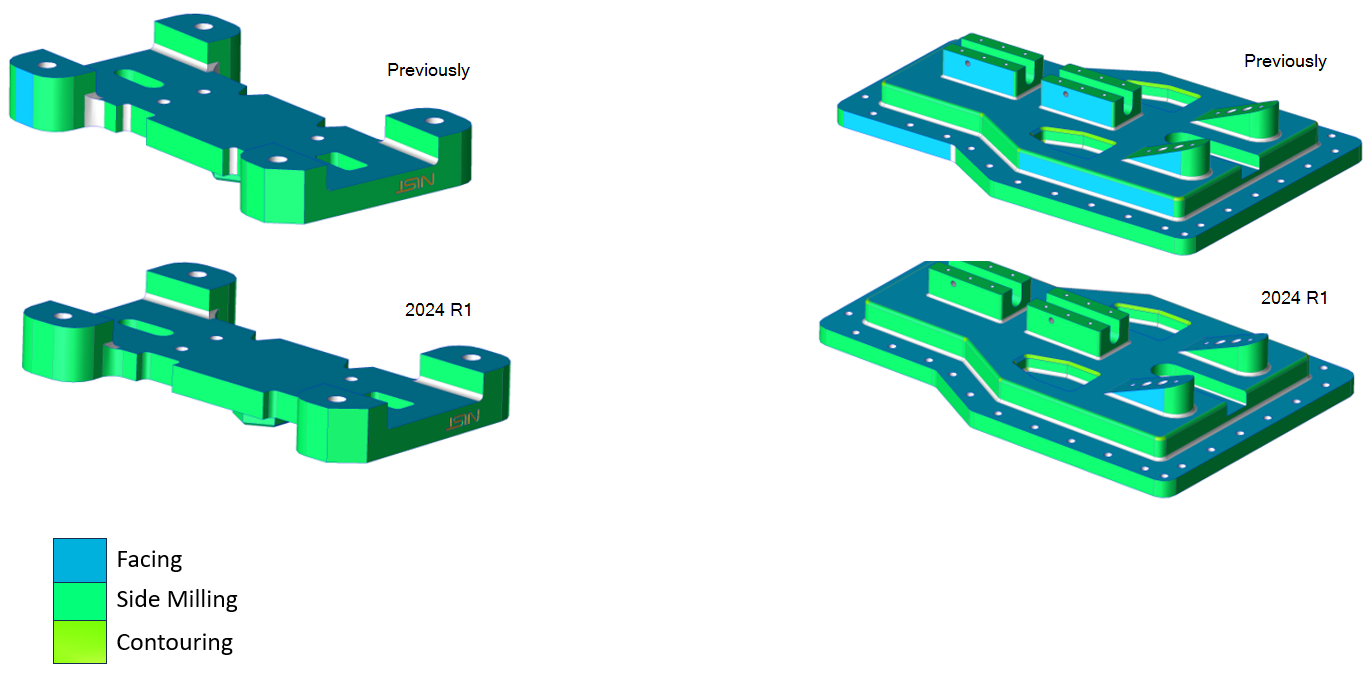

aPriori now more often assigns side milling operations to all surfaces in a “chain”, or set of adjacent surfaces that a side-milling tool reasonably would be expected to follow in actual manufacturing practice. In addition, aPriori now more accurately recognizes fillet geometry that can be made indirectly by the corner radius of a bullnose end mill. This enhancement increases the credibility of aPriori’s analysis and also modestly improves the accuracy of cycle time estimates. Previously, aPriori was more likely to assign inconsistent finish milling operations across a chain of neighboring surfaces, for example, alternating between side-milling and facing.

When finish machining, it is preferable to side mill adjacent features in a continuous single operation, using the same tool when feasible. Doing so provides a consistent surface finish, prevents witness marks between adjacent surfaces, reduces the number of tool changes, and simplifies the CNC programming.

aPriori 2024 R1 provides enhanced geometry recognition to identify chains of adjacent surfaces that are likely to be finished with the same side milling tool. Previously, Parallel Surface Chain GCDs were extracted only for chains of surfaces that were all parallel to a common direction and formed a continuous closed loop (such as the walls of a recessed pocket). Now Parallel Surface Chain GCDs also will be extracted for “open” chains of parallel surfaces. The Parallel Surface Chain GCD property Is Loop will have a value of true if the chain consists of a closed loop of surfaces and a value of false if the chain is open.

The aPriori machining process model leverages these Parallel Surface Chain GCDs to better determine when Side Milling operations should be assigned to all surfaces in the chain, as well as to determine appropriate side milling tool diameter(s). Additionally, this enhancement has improved the recognition of fillet surfaces that can be machined “indirectly” by the radius of a bull nose end mill. Now such fillet surfaces are more likely to be assigned Indirect Filleting operations instead of a less-realistic finish machining operation.

This enhancement affects parts analyzed on all routings with milling processes: 3-Axis Mill, 4-Axis Mill, 5-Axis Mill, 3-Axis Lathe, Mill Turn, and Multi-Spindle Machining routings.

Due to this enhancement, either the operation or the tool size selected to finish-mill a given surface may change, compared to the previous release. (The tool size selected for side milling operations is chosen considering the curvature of all surfaces included in the Parallel Surface Chain).

The image below shows improved operation assignment for two parts analyzed with a 4-Axis Mill routing. In the previous release, some surfaces of these parts that should have been assigned side milling were instead assigned facing. This release correctly assigns side-milling to those surfaces.

Machining cycle time estimates for a given part may change modestly, compared to previous releases of aPriori, as the finish milling operation and/or the tool size used to machine a given surface may change. Across a set of 21 representative test parts, the cycle time increased 4% on average between parts analyzed in aPriori 23.1.2 and aPriori 24.1.0 across the 3-Axis Mill, 4- Axis Mill, and 5- Axis Mill processes .

Note: To access this improved functionality you must use the latest cost model version for the Machining process group (CMV 300). In addition, you must use the latest cost model version for your primary process group, Stock Machining (CMV 200) or Multi-Spindle Machining (CMV 40).

The site variable parallelSurfaceChainAlgorithm for your primary process group (Stock Machining or Multi-Spindle Machining) should be set as follows, depending on your cost model version:

-

Open Chain (default), if you are using the latest cost model version

-

Closed Loop, if you are using a prior cost model version

Note: By default, this site variable is set to Open Chain, so all customers upgrading to aPriori 2024 R1 from earlier releases should change the value to Closed Loop if they are not simultaneously upgrading their cost model versions.

Eccentric Turning Axes Assignment Automation

aPriori now provides customers the ability to automatically estimate the cost of turned parts with off-center ("eccentric") features that are made with turning or deep boring operations, without requiring the user to designate these additional turning axes of rotation. This facilitates automated workflows (such as those involving Bulk Costing and aP Generate) and enables more accurate estimates for design engineers and other non-expert users.

aPriori has received several customer requests to support the analysis of parts that have eccentrically turned or deep bore machined geometry without the need for the user to manually assign additional turning axes in the stock machining process group.

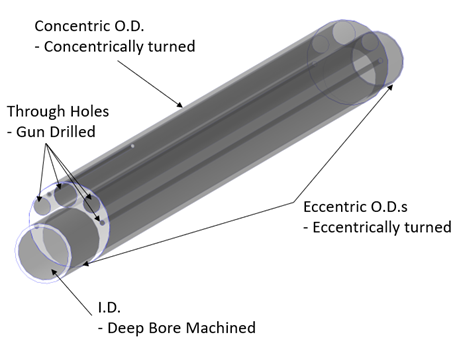

This new functionality is appropriate for any parts that have eccentrically turned features, deep bore machined features eccentric to the stock axis, or both.

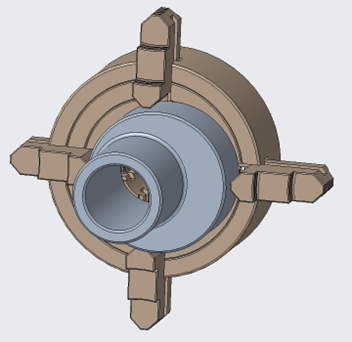

Certain part types, such as “down hole” parts in the Oil & Gas industry sector, are made from round bar or tube stock and contain rotationally-symmetric features that are offset from the stock axis. These off-center features can be made by eccentric turning operations, for example on a lathe with a 4-axis chuck. Below are two examples of these part types.

For features that are eccentrically turned, it is expected that they are set-up in a suitable 4-jaw chuck or in an appropriate turning fixture that provides the required alignment.

aPriori previously supported estimating parts made with these eccentric turning operations, but required the user to manually designate each off-center turning axis, using the Modify Turning Axis dialog in aP Pro.

Now aPriori allows customers to configure aPriori to automatically identify off-center turned features, including activating additional turning axes and assigning eccentric turning and boring type operations. With the default out-of-the-box settings, aPriori will behave as in previous releases and assume only a single axis of rotation centered on the stock axis. The table below provides guidance on how to set Stock Machining process group site variables in order to recognize off-center turned features, based on dimensions and characteristics of these features.

| Site Variable | Default | Recommended Enabled Starting Value | Description |

| turnAxisMinHoleLtoDRatio | 0 | 10 | Minimum length-to-diameter ratio that is necessary to consider a hole parallel to the stock axis as a candidate for an additional turning axis. 0 disables automatic assignment of eccentric turning axes. |

| turnAxisMinHoleDiameterMm | 0 | 31.5 | Minimum hole diameter that is necessary to consider a hole parallel to stock axis as a candidate for an additional turning axis. 0 disables automatic assignment of eccentric turning axes. |

| maxNumTurningAxes | 1 | 10 | Maximum number of possible turning axes extracted. 0 disables all automatic assignment of turning axes (both eccentric and concentric). A value of 1 (default) allows a single turning axis that is coincident with the stock axis |

This new functionality is included by default and is not separately licensed.