Usability Enhancements

aPriori 2024 R1 SP1 includes the following usability enhancements:

Manual Costing Improvements

This release enhances the manual costing capability to provide multiple benefits, including ease of use, enabling manual costing when bulk costing and when deep costing an assembly, and enabling aP Pro and aP Design to correctly process scenarios that are designated as manually cost in either application.

aPriori has long provided the capability to manually cost a part, that is, to enter a known cost for a part, rather than have aPriori mechanistically compute the estimated cost. For example, you may wish to enter a known cost for purchased hardware (for example, fasteners) or other commodity types that aPriori does not estimate, enabling these costs to be rolled up to a parent assembly. In aPriori 2024 R1 SP1, the manual costing capability was enhanced to provide multiple benefits:

-

Make it easier for users to specify that a part is manually cost.

-

Allow users to capture both commodity type (process group) and known cost.

-

Enable manual costing in the Bulk Costing & Analysis module.

-

Enable manual costing when Deep Costing an assembly.

-

Streamline workflows for loading the geometry and known costs for purchased components (such as fasteners and other standard hardware).

-

Enable aP Pro and aP Design to correctly process scenarios that are designated as manually cost in either application.

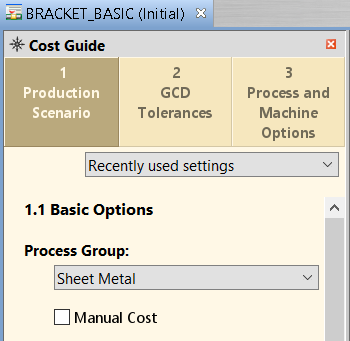

Specifying a Manual Cost with Interactive Costing

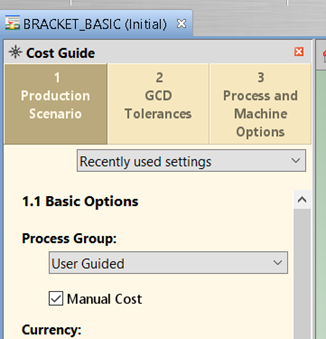

The aP Pro Cost Guide now includes a Manual Cost checkbox. Simply select this checkbox to indicate that the part cost is user-entered(as opposed to estimated by aPriori). It no longer is possible to select Manually Costed from the Process Group menu.

When you select the Manual Cost checkbox, the behavior will be slightly different for a new scenario versus a previously cost scenario:

-

For a new scenario, selecting the Manual Cost checkbox will cause the process group User Guided to be selected. If desired, you can select a different process group to further categorize the part type, but this is not required.

-

For a previously cost scenario, the previously specified process group will remain selected.

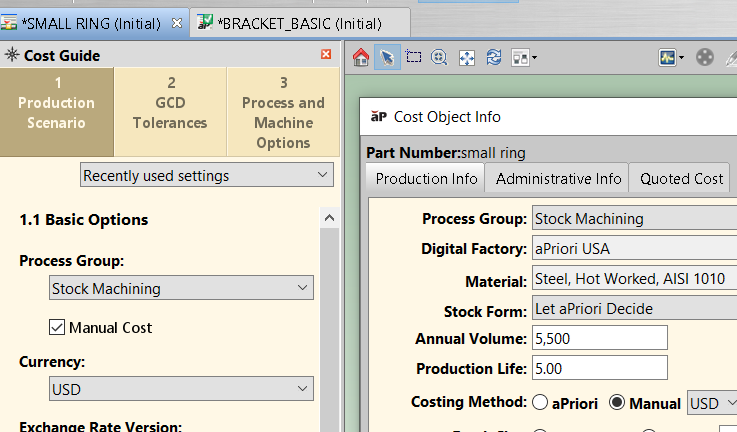

Alternatively, you can select Edit > Production Info from the Manufacturing Process pane menu, set the Costing Method to Manual, and click OK. In the Cost Guide, the Manual Cost checkbox now will be selected and stay in synch with the costing method specified in the Production Info screen.

Specifying a Manual Cost with Bulk Costing and Deep Costing

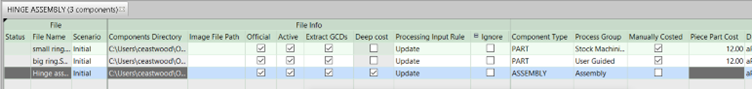

There are two changes to the aPriori Bulk Costing & Analysis screen to support efficient manual costing:

-

A new column, Manually Costed, now is available. As with interactive costing, when this checkbox is selected, the Process Group initially will be set to User Guided, but can be set to a different process group if desired to further categorize the scenario.

-

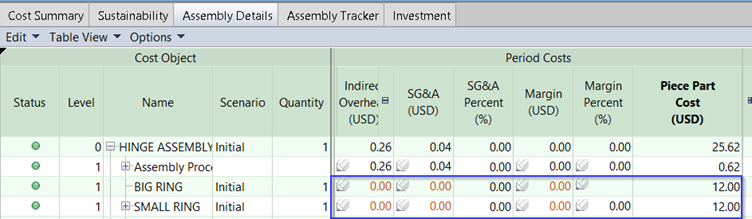

A new column, Piece Part Cost, will be displayed when Manually Costed is selected for any of the scenarios. For manually costed scenarios, you can enter a value into this column. Once the bulk costing is complete, this value will be stored in the scenario’s Piece Part Cost field, as illustrated below.

Previously, it was not possible to enter cost values for components in the Bulk Costing & Analysis screen, so an additional workflow step was required. After bulk loading the components, users could either load costs using the BOM Loader module, or directly open a scenario and enter the cost interactively.

(Note: if the bulk costing was updating a previously created scenario (Processing Input Rule set to Update), any values previously computed or entered into fields that contribute to Piece Part Cost will be discarded. These fields now will be set to 0.00 and only the new value of Piece Part Cost will be populated.)

Example: If the scenario previously had a material cost set, this will be set to 0.

Note you can also use the bulk costing input spreadsheet to specify that a scenario is manually costed and enter its piece part cost.

For more information on specifying manual (known) costs for a scenario in aP Design, please see the aP Design Release Notes.

Comparison Views now include Quoted Cost

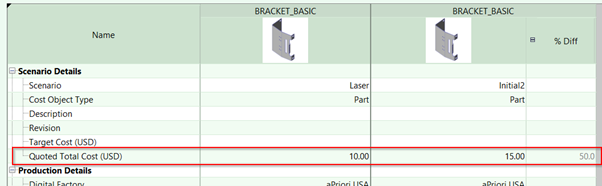

In aPriori Pro 2024 R1 SP1, quoted cost now is available in Comparison views to better support the Sourcing use case.

The Quoted Total Cost field will be displayed under Target Cost, in the Scenario Details section of the comparison. If the Quoted Total Cost values are populated, the comparison view will show the entries, and the percentage difference between the scenarios. This enables sourcing users who are evaluating different scenarios to consider quoted cost alongside other scenario data.

Deep Costing of SolidWorks Configurations Enabled

aP Pro can now perform Deep Costing on SolidWorks assemblies that reference specific configurations of sub-components.

Previously in aP Pro, Deep Costing allowed the costing of SolidWorks models only if the “Default” configuration was being costed. Deep Costing failed for SolidWorks assemblies that referenced specific configurations of sub-components. In aPriori 2024 R1 SP1, this limitation was resolved for Deep Costing, allowing users to open and deep cost assemblies that contain specific configurations.

Note: the limitation still exists for the Bulk Costing & Analysis tool. For SolidWorks files, aP Pro still has the limitation that it can only cost “Default” configurations.

Improved PMI Importing

aPriori now imports the lowest (tightest) tolerance value listed in a composite frame; previously it imported the first value. In addition, aPriori now correctly imports tolerances that reference only another tolerance; previously such tolerances were not imported.

In aPriori 2024 R1 SP1, two issues were resolved:

-

When multiple tolerances are applied to a single composite tolerance frame, aPriori used to import only the first tolerance listed. Now aPriori imports the lowest tolerance value listed in a composite frame.

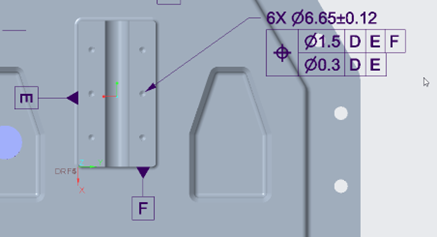

For example, with the position tolerance shown below, aPriori now will import a tolerance of 0.3:

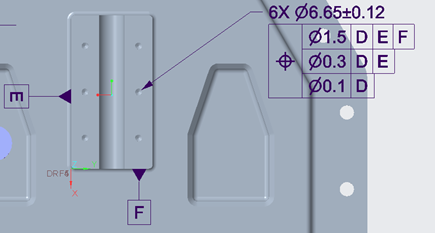

Note: there is a known limitation for Creo and Catia CAD models that allows aPriori to read only the first two tolerances specified in a composite tolerance frame. Hence, if the example above was extended to have three positional tolerances, then the third tolerance value of 0.1 would not be imported, despite being the lowest (tightest) value:

-

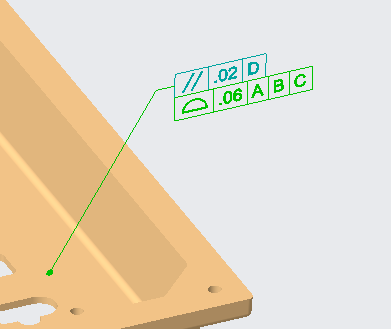

Previously for Creo CAD models, aPriori could not read a tolerance annotation that referenced only another tolerance, as it didn’t read the referenced surfaces from that parent tolerance. Now aPriori will correctly import values from tolerance annotations that reference other tolerances.

For example, the Profile of Surface tolerance shown below was not imported previously, as it references only the parallelism tolerance to which it is attached. Now the designated surface will be assigned both a parallelism tolerance value and a profile of surface tolerance value: