2-Model Machining Enhancements

Intelligent Automated Alignment of the "Source" and "Finished" CAD models

Users now can analyze parts in the 2-Model Machining process group even when the "source" and "finished" CAD models are not oriented consistently with respect to a common default coordinate system. Previously these “misaligned” part pairs could not be analyzed in aPriori, and needed to be re-modeled in the CAD system to establish a common coordinate system and consistent orientation in 3D space.

The 2-Model Machining process group enables you to accurately cost a part if you have two CAD models:

-

One CAD model that represents the part after its initial processing (typically a net-shape part, such as a casting or forging). This is referred to as the “source” model.

-

A separate CAD model that represents the finished, machined part. This is referred to as the “finished” model.

By comparing the two models, aPriori can automatically identify machined features and the amount of material removed, providing a highly accurate determination of the machining operations and cycle times required.

Prior to this release, aPriori used a simple approach to aligning the CAD models in 3D space—it simply aligned the default coordinate systems of the two models. A majority of the time this approach properly aligned the source and finished models, so that the models were oriented consistently and the finished model was contained within the source model. However, when the two models did not share a common default coordinate system, they would not be positioned properly relative to one another, and aPriori would fail to cost the finished model. Instead, aPriori would display the messages Probable CAD model misalignment detected (in aP Pro) and Machined model extends outside source model (in aP Pro and aP Design)

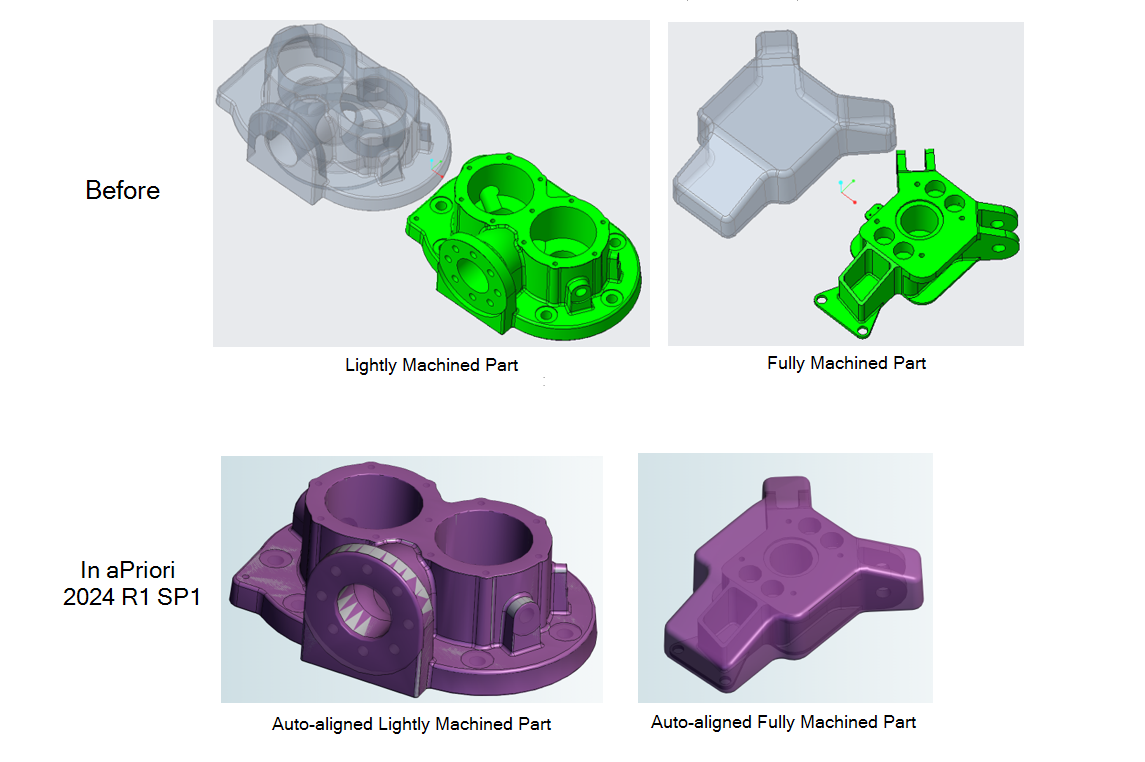

In this release, aPriori introduces sophisticated algorithms which compare the solid geometry of the source and finished CAD models in order to align them in 3D space, rather than relying on the default coordinate systems. The pictures below show two different part pairs as examples. The “Before” picture represents how the parts would be oriented relative to one another, based on their coordinate systems. Unfortunately, they do not overlap in 3D space, preventing aPriori from performing the analysis. The second image represents how the parts are aligned in aPriori 2024 R1 SP1, using the new alignment algorithms

Note that the new alignment algorithms support all the following situations:

-

"Lightly machined" cases, where the finished part retains some or many of the original surfaces from source (net-shape) model. For example, in the first pair of parts above, some holes are drilled and some surfaces are faced to produce the finished model, but many of the cast surfaces are untouched.

-

"Fully machined" cases, where no original surfaces of the source model are preserved

-

Situations in which the source and finished CAD models have different unit systems (for example, one in Imperial units and one in metric units). Previously this was not supported and users were required to manually change the unit system in the CAD model to enable aPriori to analyze them in the 2-Model Machining process group.

Impact

This enhancement enables aPriori to analyze part pairs that are not positioned and oriented consistently with respect to their default coordinate systems. However it has no effect in cases where the parts are positioned and oriented consistently and could be analyzed successfully in previous releases. For these part pairs, manufacturing estimates and DFM feedback are expected to be the same in aPriori 2024 R1 SP1 as in previous releases.

Known Limitations

In some cases, aPriori still fails to properly align a source model and a finished model, particularly in the “fully machined” case where none of the original surfaces from the source (net shape) model are preserved.

Workaround: If aPriori is unable to automatically align the models properly, you may be able to modify the CAD models to enable aPriori to analyze them. Refer to the section Part alignment in the 2-Model Machining chapter of the 2024 R1 SP1 version of the aPriori Cost Model Guide for more information. Alternatively, please visit the aPriori Knowledge Base in the support site and see the article titled “How to manage misaligned parts in 2-model machining”.

.