Machining Enhancements

Carbon Estimates for Machining Auxiliary Energy

aPriori 2024 R1 SP1 expands energy consumption calculations to incorporate auxiliary power requirements for the machines.

In aPriori 2024 R1 SP1, machining process carbon estimates now include auxiliary energy consumption. This is energy consumed to support the machine's non-cutting components (for example, coolant pumps, chip conveyors, and so forth). Previously, aPriori provided estimates only for carbon emissions due to the energy required for the machine’s spindle to remove material from the workpiece.

To account for auxiliary energy, an additional machine property called Auxiliary Power has been introduced. This considers the power requirements of the auxiliary components, providing a more comprehensive understanding of the process's carbon footprint. Auxiliary Power is applied across the entire machining cycle, including previously unaccounted times like part setup time. This allows for a more accurate estimation of the total energy consumption.

As part of this implementation, the rated and spindle (cutting) machine property fields were reviewed for every machine in the Machining process group, see Updates to Machine Rated and Spindle Powers for more information.

An impact analysis was conducted on 156 parts across a range of primary process groups. This analysis showed a direct relationship between machining cycle time and energy consumption. The greater the machining cycle time, the greater the increase in energy consumption. This is expected behavior as auxiliary power is required throughout the machining cycle. Parts with large cycle times for secondary machining also saw significant increases in overall energy consumption.

Due to this enhancement, energy consumption estimates will increase significantly compared to the previous release of the Machining process model. An impact analysis was conducted on 156 parts across a range of primary process groups. This analysis showed a direct relationship between machining cycle time and energy consumption. Given this relationship and the variance in auxiliary power across machine types and sizes a large range of energy consumption increases were observed. The average increase in energy consumption was 39 kWh. The largest increase in energy consumption being seen on a part with 94,605 seconds (26.2 hours) of machining cycle time, this increase was nearly 890 kWh.

Important: A check was introduced into the Machining process group to ensure the sum of the main cutting tool power and the auxiliary power does not exceed the total rated power of the machine. This check will apply to all customers (including those without a sustainability license) once the manufacturing process model is upgraded to this latest version (CMV 310). As a result, an Auxiliary Power value will need to be populated for all custom machines in the Machining process group. If this is not known, the value from a similar baseline machine type and size could be leveraged. This value can be set to zero if the auxiliary power requirements for a given machine are negligible, such as for older machines with little-to-no auxiliary equipment.

Note: These updates to machine power values and therefore overhead values are available only to customers using the 2024-06 RDLs in conjunction with aPriori 2024 R1 SP1. For customers using the aPriori 2023 R1 releases, the previous machine power values are still in effect and overhead rates are not affected by the power updates describe above.

Updates to Machine Rated and Spindle Powers

The 2024-06 Regional Data Libraries have reviewed and updated all machine rated and spindle (or cutting) powers in the Digital Factory.

In the 2024-06 Regional Data Libraries, significant updates were made to machine power values, as part of the implementation of Carbon Estimates for Machining Auxiliary Energy. Following a review of all machining processes, many updates were made to the values of machine spindle (or cutting power) and/or machine rated power to ensure agreement with published machine specifications and to provide consistency across machines in a given process.

When machine power rates were updated, machine direct overhead rates were directly affected as annual energy usage is an input to the Direct Overhead calculation. Additionally, in some cases, customers also may see some minor changes in machine selection and cycle time calculations. By default, aPriori selects a feasible machine with the lowest total overhead rate; relative changes in powers between two feasible machines may change this selection. aPriori calculates machining cycle time based on available spindle power to determine feed and speed rates. Modifications to the machine's spindle power or cutting power may affect these calculations, potentially altering cycle times. This may affect other cost calculations such as indirect overhead costs.

An impact analysis on 104 parts using aPriori baseline machines revealed an average increase of 13.6% in direct overhead costs and a minimal change (0.2%) in indirect overhead costs for parts analyzed in the Stock Machining or 2-Model Machining process groups. In a separate analysis, 113 parts cost against various process groups showed an average increase of 11.7% in direct overhead costs and a minor increase (0.4%) in indirect overhead costs, when secondary machining was involved.

Note: Customers who have previously created custom machines utilizing a baseline machine's power values may want to review and update the custom machine values similarly. This could be performed while also adding the Auxiliary Power values described in Carbon Estimates for Machining Auxiliary Energy.

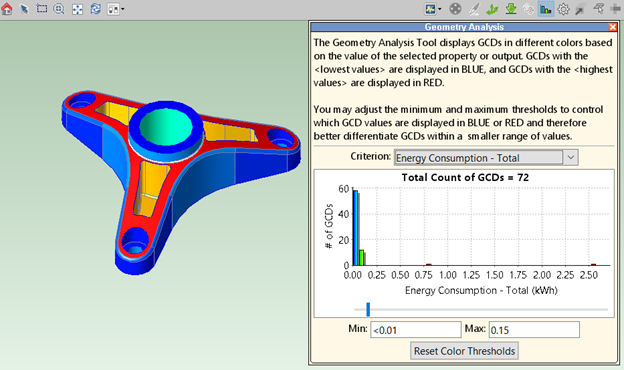

Energy Consumption available in the Geometry Analysis Tool

aPriori 2024 R1 SP1 introduces three energy consumption variables into the Geometry Analysis tool (also known as the Heat Map).

In aPriori 2024 R1 SP1, machining energy consumption has been added to the Geometry Analysis tool. After costing a part with the Stock Machining process group, you can now visualize the energy consumed during the machining of each GCD. Three views are available:

-

Auxiliary Energy Consumption– This is energy consumed to support the machine's non-cutting components (for example, coolant pumps, chip conveyors, and so forth).

-

Cutting Energy Consumption – This is the energy consumed for the spindle to remove material.

-

Energy Consumption – Total – This is the total energy required to manufacture the part. This is the sum of Auxiliary Energy Consumption and Cutting Energy Consumption.

Improvements to Tool Selection and Standard Hole Size Feedback

aPriori 2024 R1 SP1 provides improved tool selection and Design-to-Cost feedback regarding standard versus non-standard drill sizes.

In aPriori 2024 R1 SP1 , improvements have been made to the tool selection logic for the Machining process group's Drilling and Pecking operations. Previously, the largest drill diameter that was within the hole size tolerance limits would be selected. Two distinct modifications have been made to this logic:

-

If a hole size exactly matches an available tool size, this tool will now be selected.

-

If a hole does not exactly match an available tool size, the next smallest drill bit (if available) will be selected. Otherwise, the smallest drill bit that fits within the tolerance range will be selected (this will be larger than the nominal hole diameter).

This update will be primarily visible in the Holes and Fillets design feedback. In some cases, it may also affect the number of unique tools required, overall machining time, and ultimately, the part's cost.

Machining Milling Code Refactored

The logic for milling operations and processes was refactored for code clarity and ease of maintenance. Multiple issues found during the refactoring effort also were addressed.

In aPriori 2024 R1 SP1 as well as in the preceding release, aPriori 2024 R1, the Machining manufacturing process models were updated to improve the clarity and maintainability of the code. In particular, code related to determining part setups and tool approach directions was refactored. This was a comprehensive code update, affecting all machining operations available across the various machined GCD types, in the 3-Axis Mill, 4-Axis Mill, and 5-Axis Mill processes. These updates will make it easier to enhance the Machining model in the future, and for customers to configure the model if desired.

While generally these updates were not intended to change manufacturing estimates, various miscellaneous issues discovered during the refactoring effort were addressed. As a result, users may see isolated differences in the operation or the setup axis selected for a given GCD, or the cycle time computed for an operation, compared to a previous release of aPriori.

In particular, for holes or slots that were accessible from two equal and opposite directions, previously aPriori sometimes incorrectly selected a setup that would require the tool to approach from the “far side” of the feature, instead of the near side, and therefore require an excessive tool reach. As a result, aPriori both would display Long Tool Reach DFM feedback, and significantly reduce the feed rate to compensate for long tool reach, unnecessarily inflating the cycle time estimate for that feature. These types of errors are now much less likely to occur.

Additionally, aPriori 2024 R1 SP1 fixes an issue which occurred for 4-Axis Mill routings when the user assigned a different setup axis to a surface GCD. Previously, a General Mill Finishing operation was assigned incorrectly to the surface, even when Facing, Side Milling, or Contouring operations were in fact feasible. Now the expected surface finishing operation will be assigned.