Assembly Enhancements

This release includes the following enhancements to the Assembly process group:

Machine Power Updates

The 2024-09 Regional Data Libraries provide updated machine rated power values for various mechanical assembly, bonding, and welding processes.

Machine rated powers were updated following a review of all machines in the Assembly Process Group. This review was conducted in parallel with implementing carbon estimates for the Assembly Process Group. The following machine powers were updated:

|

Process |

Machine |

Previous Power (kW) |

Updated Power (kW) |

|---|---|---|---|

| Adhesive Bonding | Robotic Adhesive Bonding | 10 | 5.11 |

| Electron Beam Welding | Electron Beam Welder Load Lock – 7500 Watts | 7.5 | 11.25 |

| Lock Bolt | All Machines | 1 | 0.83 |

| Manual MIG Welding | C240 (ESAB – 20A to 220A) | 10 | 5.24 |

| Manual MIG Welding | C280 (ESAB – 30A to 280A) | 10 | 7.60 |

| Manual MIG Welding | C420 (ESAB – 50A to 420A) | 10 | 13.50 |

| Manual MIG Welding | Default MIG Weld | 10 | 13.50 |

| Manual MIG Welding | Deltaweld 653 (Miller) | 10 | 30.7 |

| Manual Spot Welding | Default Spot Weld | 10 | 12.46 |

| Manual Spot Welding | LMSW (Miller – 152mm tongs) | 10 | 5.61 |

| Manual Spot Welding | MSW (Miller – 152mm tongs) | 10 | 2.81 |

| Manual Spot Welding | SSW (Miller – 152mm tongs) | 34 | 20.70 |

| Manual Spot Welding | SSW (Miller – 305mm tongs) | 10 | 20.70 |

| Manual TIG Welding | Default TIG Welding | 10 | 10.04* |

| Manual TIG Welding | Maxstar 400 3 – 400A (Miller) | 10 | 10.04 |

| Manual TIG Welding | Maxstar 800 5 – 800A (Miller) | 10 | 24.41 |

| Manual TIG Welding | MINIARC 161LTS 5 – 160A (ESAB) | 10 | 4.22 |

| Pick and Place | Default Pick and Place | 10 | 0.00 |

| Rivet | Default | 10 | 0.25 |

| Robotic Spot Welding | All Machines | 10 | 15.26 |

| Robotic TIG Welding | All Machines | 10 | 9.24 |

| Threaded Insert | Threaded Insert | 10 | 0.25 |

*Proxied using the Maxstar 400 3 – 400A (Miller)

Due to the updated values of machine power, estimated overhead rates and costs may change very slightly for assembly operations, compared to the previous release. In a small test set, a maximum change of $0.03 in direct overhead cost was observed.

Updates to Multi-Body Interpretation for STEP Assembly Files

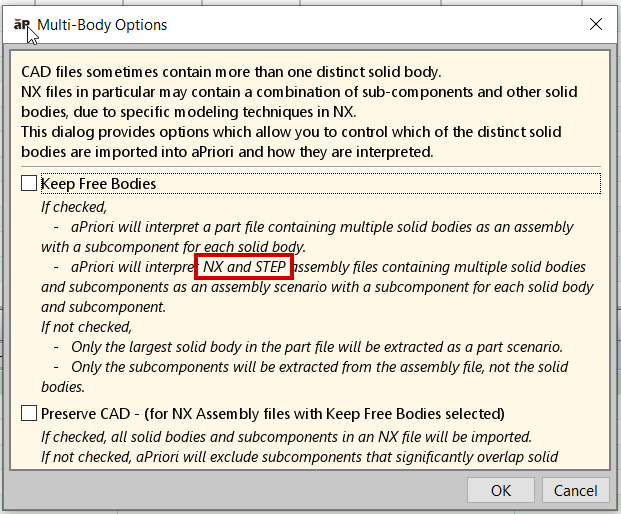

In 2024 R1 SP2, the Multi-Body Options setting Keep Free Bodies was extended to apply to STEP assemblies containing solid bodies, ensuring assembly subcomponents can be interpreted correctly and consistently for both STEP files and native CAD files.

This enhancement affects how aPriori interprets solid bodies that are defined within an assembly STEP file and are not distinct (separate) part STEP files referenced by that assembly. Note that this enhancement also addresses an issue introduced in a previous release:

-

Before aPriori 2023 R1 SP3, aPriori always interpreted a solid body within an assembly STEP file as a part. Beginning in aPriori 2023 R1 SP3, aPriori behavior changed unintentionally, due to a change in underlying 3rd-party libraries. As a result, solid bodies defined within an assembly STEP file were neglected and were missing from the aPriori scenario. There were no options available for users to change this interpretation.

-

Now, in aPriori 2024 R1 SP2, the interpretation of solid bodies in STEP assemblies is controlled by the Multi-Body Options dialog. The first option, Keep Free Bodies, now applies to STEP assemblies that contain solid bodies, and this option should be selected (checked) to import these solid bodies into aPriori as part scenarios. This is consistent with aPriori’s behavior when it interprets native NX assemblies containing solid bodies.

The Multi-Body Options dialog now refers to STEP files as well as NX files, for clarity: