Forging Enhancements

aP Pro 2024 R1 SP3 provides the following updates to the Closed-Die Forging manufacturing process model:

Please note that this is the first release in a series of planned enhancements to the Closed Die Forging manufacturing process model. Further enhancements will be released in aP Pro 2025 R1 and aP Pro 2025 R1 SP1. Customers who already are using a configured Closed-Die Forging model may wish to delay upgrading their manufacturing process model until these additional enhancements are available. Please consult your aPriori account team or aPriori Support for planning purposes.

Improved Estimates of Material Volume and Utilization

aPriori 2024 R1 SP3 provides more accurate calculations of the volume of material required to manufacture a forged part, the dimensions of the mult and stock, and the resulting estimates of material utilization and cost.

This release improves the computation of the mult volume required for a given forging and the resulting estimate of material utilization in a number of ways:

-

Part complexity is now considered when estimating flash volume.

-

Scale loss is now included in the determination of required material volume.

-

More intelligent logic is used for calculating the volume of pierced material.

-

Kerf width lost during cutting of the stock into mults is now calculated and used in the material utilization estimate.

-

Stock End loss is now calculated and used in the material utilization estimate.

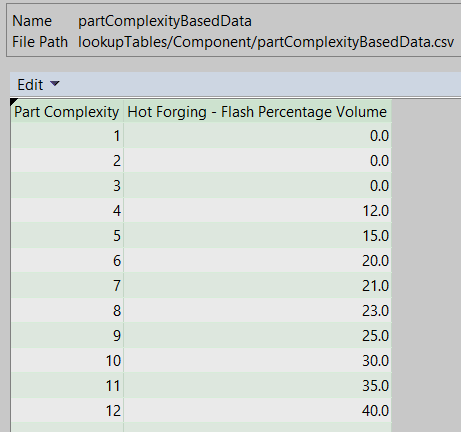

The highest-impact enhancement is the first bullet above. aPriori now determines a part complexity score (on a scale from 1 to 12). This part complexity score is used to estimate the amount of additional material, above and beyond the volume of the forged shape, that is required to ensure the mold is sufficiently filled. This additional material becomes flash. Parts with higher complexity scores require more flash. The following table shows how part complexity determines flash percentage:

aPriori has developed an innovative approach for assessing part complexity and using this complexity score to inform manufacturing estimates. This approach was developed based on a combination of reputable academic research and consultation with forging industry subject matter experts. aPriori takes the following approach to the determination of part complexity:

-

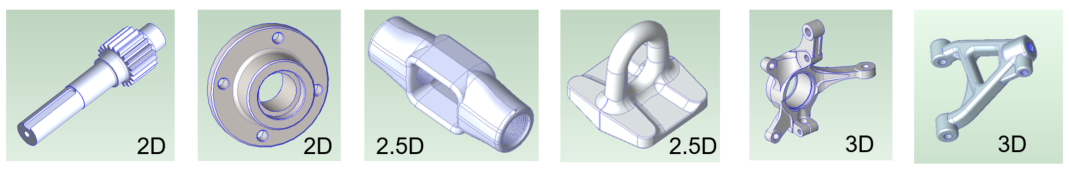

Complexities 1 to 3 have zero flash because they are 2D—almost fully rotationally symmetric parts. By default, the cost model classifies a part as 2D if at least 95% of its surfaces are about a turning axis.

-

Complexities 4 to 7 are associated with 2.5D parts. 2.5D parts have reflection symmetry and, in some cases, partial rotational symmetry as well.

-

Complexities 8 to 12 are associated with fully 3D parts.

The image below shows sample parts that illustrate the three broad complexity categories:

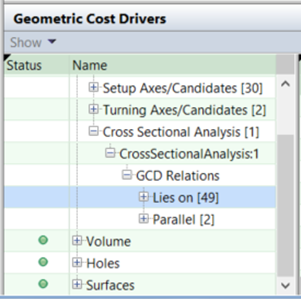

The cost model uses the new GCD Cross Sectional Analysis to determine whether a part is 2D, 2.5D or 3D, and to determine where on the complexity scale the part lies. During geometry extraction, the part is sliced along an axis to determine how both the cross sectional area and the center of area (the geometric analogue of center of mass) vary over the length of the part, giving a good measure of deformation. More information on the new GCD and logic for determining complexity can be found in the Cost Model Guide.

The new GCD has two useful visualization tools for end users:

-

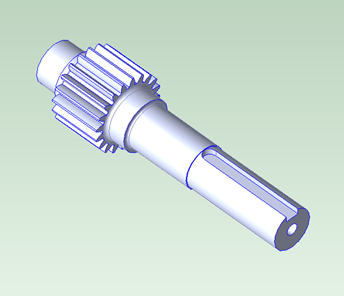

Select the GCD in the Geometric Cost Drivers pane to add a heat map to the model in the Viewer. The red color represents the maximum cross-sectional area and blue the minimum cross-sectional area for the part. Regions where colors move from red to blue over a short distance indicate a large and abrupt deformation, which increases part complexity. Below is an example:

Important: The presence of red in the heatmap does not by itself indicate deformation or complexity; deformation and complexity are indicated by rapid transitions from one color to a dissimilar color (that is, another color that is not adjacent to it in rainbow order: red, orange, yellow, green, blue).

-

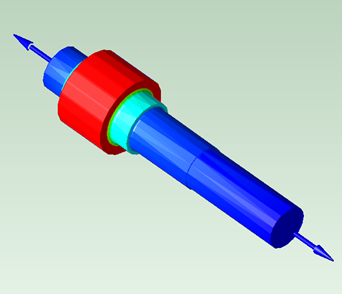

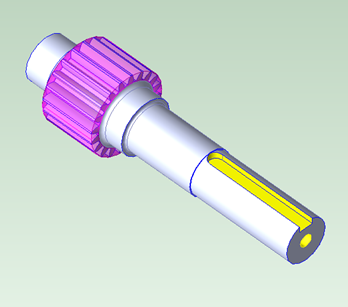

aPriori automatically identifies features that likely are machined from the raw forging. aPriori estimates the volume of the pre-machined geometry for the purpose of computing required material volume, material cost, and utilization. When you select the Lies On Relation under the CrossSectionalAnalysis GCD in the Geometric Cost Drivers pane, the Viewer highlights features that are assumed to be machined. In the picture below, the gear feature, the keyway feature, and the hole feature are assumed to be machined. Note that in the picture above, the heatmap displays the pre-machined geometry and does not include the machined features in its measures of cross-sectional area. Machined features are not included in the analysis of variation in cross-sectional area and center of area.

Improved Material Stock Selection

aPriori 2024 R1 SP3 updated and enhanced the stock selection logic for Forging, helping to ensure aPriori selects a reasonable stock.

aPriori 2024 R1 SP3 improves stock selection logic by updating the criteria for selecting valid stocks and evaluating multiple valid stocks to select the cheapest one.

aPriori now evaluates up to 5 different stock sizes and selects the cheapest option. This change significantly increases the robustness of the model and accuracy of stock selection. Digital Factory administrators can control the number of stocks evaluated by changing the value of the cost model variable validMaterialStocksListLimit. Set the value to 1 to match the previous behavior and evaluate only one stock. is Set the value to 0 to ignore all actual stocks and instead use a virtual stock.

The logic for determining whether a stock is valid also was updated. Previously aPriori considered only the stock form and the mult size ratio (mult length to mult width) to determine whether a stock was valid. Now aPriori checks that:

-

Mult dimensions are in range relative to part dimensions, considering the mult orientation (flat or upright).

-

Mult length is no greater than stock length.

-

Mult ratio is in range, for upright stocks only.

Once the list of valid stocks is determined, aPriori evaluates them in order of estimated utilization. Note that estimated utilization and calculated utilization can vary depending on the routing being evaluated.

For more information, see Stock Selection for Closed Die Forging in the Cost Model Guide.

The next release of aPriori will extend the logic further by evaluating multiple virtual stocks, to ensure aPriori selects an appropriate virtual stock.