Design Guidance Enhancements

aPriori 2025 R1 SP1 provides several design guidance enhancements across multiple process groups. These enhancements collectively improve the quality of guidance provided to design engineers, ensuring they receive impactful feedback that enhances the quality of part designs.

- Enhanced Visualization Short Shot Condition

- Hole Proximity Improvements in Plastic Molding, Casting-Die, Casting-Sand and Casting-Investment

- Plastic Molding Blind Hole L/D Feedback

Enhanced Visualization Short Shot Condition

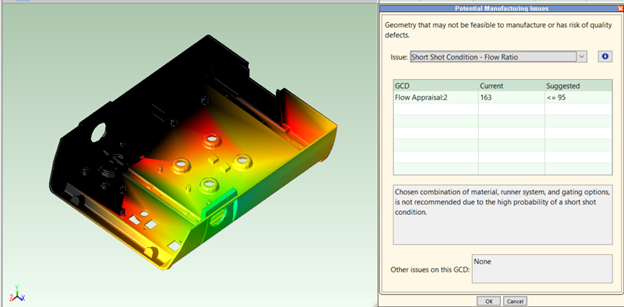

aP Pro improves the visibility of short shot conditions by displaying a visualization of the Flow Appraisal GCD on the CAD model in the Viewer when you review a Short Shot Condition – Flow Ratio design issue.

In aP Pro, the latest version of the Plastic Molding process model (CMV 290) introduces automatic visualization of the Flow Appraisal GCD when you review a Short Shot Condition design issue. This enhancement enables design engineers to more easily identify and understand short shot conditions.

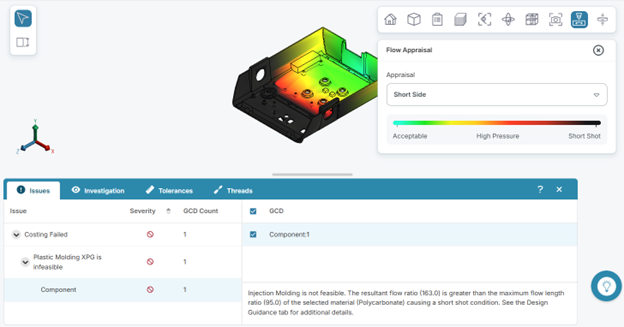

Additionally, in aP Design, you can now display a visualization of the Flow Appraisal GCD in the 3D viewer by selecting the Flow Appraisal button in the toolbar. When aPriori identifies a Short Shot Condition, design engineers can review the failure message and select the Flow Appraisal button to visually inspect the short shot condition directly on the model.

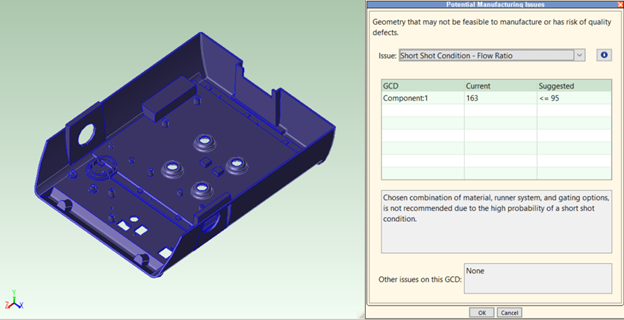

Previously:

aP Pro, CMV 290:

aP Design (click Flow Appraisal button in the toolbar):

Hole Proximity Improvements in Plastic Molding, Casting-Die, Casting-Sand and Casting-Investment

aP Pro now enhances the identification of hole proximity issues in the Plastic Molding and casting process groups.

Hole proximity is an important design consideration in molding processes. Holes that are placed too close to one another or too close to the edge of a part can impact material flow, potentially leading to issues such as incomplete filling, weld lines, or air traps. These potential defects can lead to quality issues with the final part. Additionally, insufficient spacing between holes can weaken the mold structure, making the tooling more fragile and increasing the risk of mold failure.

Previously, aPriori’s hole proximity feedback correctly flagged holes that were too close to each other or too close to the edge of the part. However, aPriori also often generated some false-positive feedback, flagging proximity issues for pairs of surfaces that did not in fact represent a wall thickness issue. This false-positive feedback was due to certain approximations and simplifications in the manufacturing process model.

The latest versions of the manufacturing process models for Plastic Molding (CMV290), Casting – Die (CMV 210), Casting – Sand (CMV 210), and Casting – Investment (CMV 120) provide enhanced geometry analysis and design guidance logic to improve the accuracy of hole proximity feedback. This enhancement significantly reduces the number of false-positive proximity issues while retaining valid ones, enhancing the quality of the feedback provided by aPriori.

The amount of reduction varies by process groups, with Plastic Molding and Investment Casting decreasing the most (due to their typically smaller part size). The table below shows the amount of reduction observed for a large test set of representative part types:

| Process Group | Average Reduction in Issues |

|---|---|

| Plastic Molding | 82% |

| Casting – Die | 25% |

| Casting – Sand | 51% |

| Casting – Investment | 82% |

Additionally, the Hole Proximity secondary help guidance for casting process groups was updated to ensure the impact and advice statements are relevant and actionable.

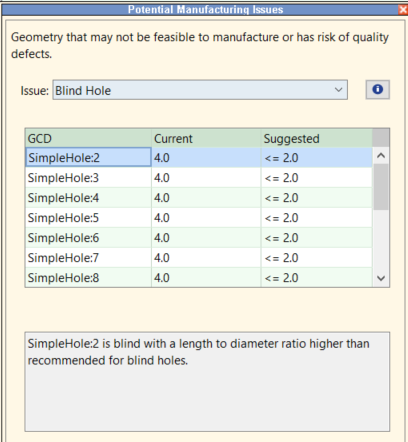

Plastic Molding Blind Hole L/D Feedback

aP Pro streamlines the feedback provided to design engineers when blind holes exceed recommend length-to-diameter ratios in Plastic Molding.

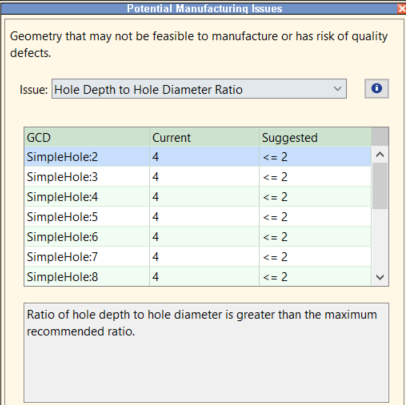

Previously, aPriori flagged blind holes that exceeded recommended length-to-diameter (L/D) ratios twice—once under the Blind Hole issue category and once under the Hole Depth to Hole Diameter Ratio issue category, as shown below for SimpleHole:2.

The latest version of the Plastic Molding process model (CMV290) removes the duplicate feedback. L/D issues for blind holes are displayed only within the Blind Hole issues category. L/D issues for through holes are displayed in the Hole Depth to Hole Diameter Ratio list.