Design Guidance Enhancements

aPriori 2025 R1 SP2 provides the following design guidance enhancements:

- New Design Guidance for Forging

- Easily Enable or Disable Evaluation of Design Guidance Checks

- Enhanced Design Guidance Messaging

- Dynamic Units Updates in Design Guidance Secondary Dialogs

New Design Guidance for Forging

aPriori 2025 R1 SP2 provides Design For Manufacture and Design To Cost feedback in the Forging process group.

The latest Forging model (CMV280) now detects and alerts the user to various manufacturability and cost-driving design issues for closed die forged components. Forging manufacturability and cost-driving feedback provided includes:

-

High Blind Hole Diameter to Depth Ratio: Punches forming blind holes are subjected to significant compressive and lateral forces. Their stiffness is drastically reduced by higher length-to-diameter (L/D) ratios, making them highly susceptible to buckling or bending under forging loads. This vulnerability leads to punch breakage or the formation of deformed holes.

-

Inaccessible Feature: An undercut (that is, a volume that is inaccessible from the draw direction) prevents proper ejection of the part from the forging die. The part cannot be successfully forged.

-

Insufficient Corner and Fillet Radius: Inadequate corner or fillet radii create significant issues by impeding metal flow throughout the die cavity. This exacerbates flow resistance and may cause incomplete die filling or cause the metal to fold back over itself ("laps") to fill voids created as a result of the metal failing to follow sharp corners or fillets. It can also lead to excessive die wear.

-

Insufficient Draft Angle: Inadequate draft angles create significant issues by increasing friction and prolonging contact between the workpiece and the cooler die surface. This exacerbates flow resistance and promotes rapid cooling, ultimately causing incomplete die filling. It also leads to excessive die wear from abrasive friction and severe sticking during ejection, causing galling that damages subsequent parts.

-

Thick Slug: Punching excessively thick webs elevates the risk of the punch bending, chipping, or fracturing due to immense concentrated stresses. Such punching yields low-quality features characterized by large burrs, rough fracture zones, and inconsistent geometry. The high punching forces can also deform, bulge, or even crack the surrounding forged material, particularly in thin wall sections.

-

Thick Walled Hole: Excessively thick walls around forged holes impede optimal grain flow and hinder overall metal filling. This often leads to non-uniform cooling, causing underfills and inconsistent mechanical properties in the finished part, such as reduced hardness, strength, or ductility.

-

Thin Section: The large surface-area-to-volume ratio in overly thin sections causes rapid cooling and increased flow resistance, which can lead to incomplete die filling. It can also result in sub-optimal grain flow, which negatively impacts mechanical properties such as strength, and potentially initiates fatigue cracking. Thin webs are also susceptible to deflection or bending during ejection and can crack due to internal stresses if the part is improperly removed.

-

Threaded Holes: Threaded holes cannot be manufactured using forging operations. Machining is required.

-

Tight Tolerance: Additional processing may be required to achieve the specific tolerance or avoid quality defects.

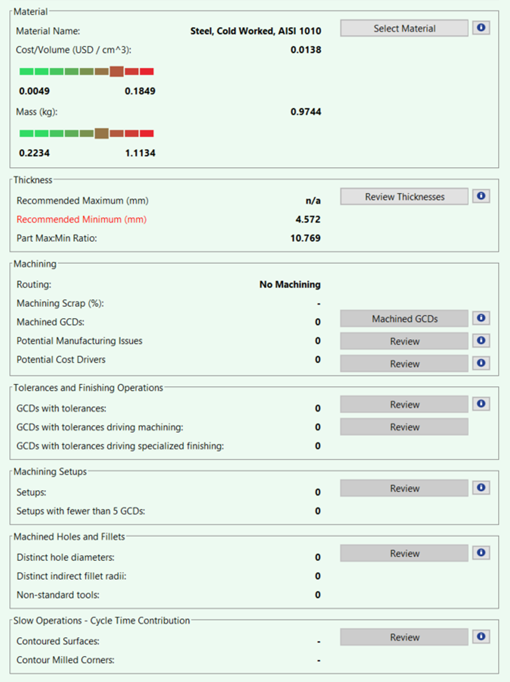

Additional design guidance feedback is available for Forged parts in other sections of the Design Guidance tab, consistent with feedback available in casting and plastic molding process models. Design engineers can get feedback on:

-

Alternative materials

-

Thin sections of the part visualized

-

Machined features

-

Features with tolerances

-

Machined Holes and Fillets

-

Slow machined features

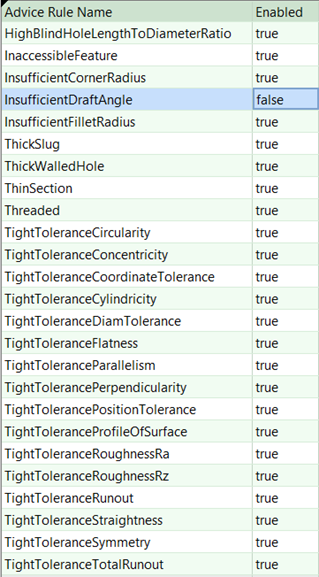

Easily Enable or Disable Evaluation of Design Guidance Checks

The latest Forging and Plastic Molding process models (CMV280 and CM300, respectively) provide Digital Factory managers with more control over design feedback. Digital Factory managers can now easily configure which design guidance checks are evaluated by the model. This ensures engineers only receive feedback that is relevant to their design standards.

To enable or disable a specific design guidance check, open the Digital Factory Manager module and find the Lookup Table named adviceRules under the manufacturing process group of interest. For example, draft angles can sometimes be noted on 2D drawings and not modeled in 3D CAD. In such cases Digital Factory managers can set InsufficientDraftAngle to false (shown below), deactivating unnecessary draft angle feedback. This configuration table makes it easy to tailor feedback so that aPriori flags only actionable issues.

The ability to enable and disable design guidance checks will be added to other process groups in future releases.

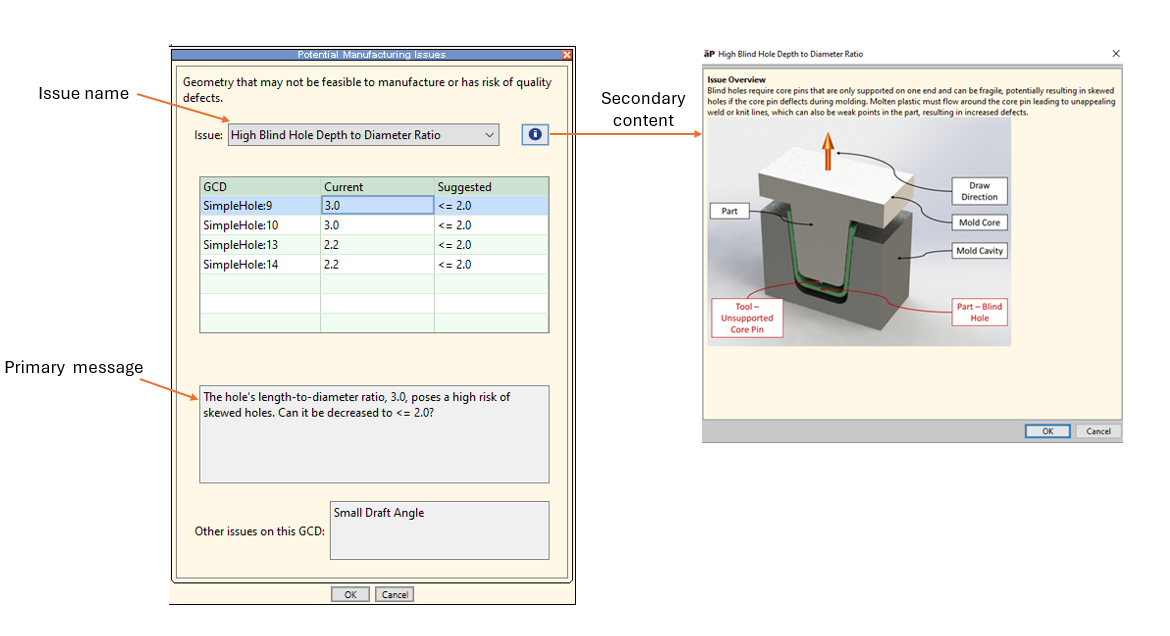

Enhanced Design Guidance Messaging

The latest Forging and Plastic Molding process models (CMV280 and CMV300, respectively) provide improved design guidance to help engineers resolve issues faster.

The latest Forging and Plastic Molding process models (CMV280 and CMV300, respectively) provide enhanced design guidance messaging to help design engineers understand each design issue and how to address it. Previously, in some cases, design guidance issue names did not clearly identify the problem with the design and/or the primary message did not provide a recommended action to resolve the issue.

Now:

-

Clear and relevant issue names: Issue names have been updated to consistently reference the design related root cause

-

Actionable primary messages: The primary message for each issue highlights the likely impact and gives clear advice on how to resolve it.

-

Secondary help content: Secondary content which provides additional details, often with supporting images are available as educational resources.

These updates ensure design engineers have the right context, impact information, and guidance to resolve issues more efficiently.

Dynamic Units Updates in Design Guidance Secondary Dialogs

Units in design guidance secondary dialogs now dynamically update when a user modifies the unit system settings.

aP Pro 2025 R1 SP2 improves design guidance usability by ensuring the units displayed in secondary popup dialogs update dynamically when a user changes unit system settings (via the View > Unit System Settings menu option) . Previously, popups did not refresh automatically when switching from metric to English (or vice versa), requiring users to close and reopen the scenario or re-cost to see updated units. Now, design guidance popups always reflect the current unit system settings—without the need to refresh the UI or close the popup.