2-Model Machining Enhancements

Improved Alignment of Source Models and Machined Models

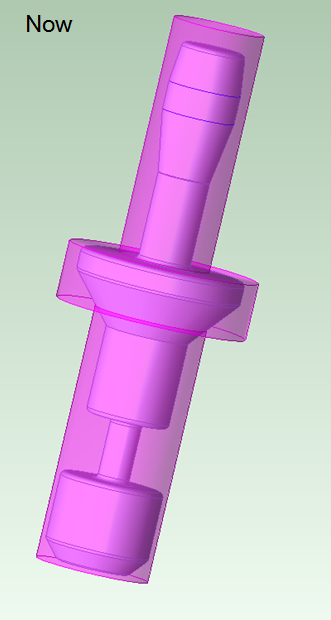

The auto-alignment algorithm now better aligns turned (rotationally symmetric) parts with their net shape parts, in the axial direction.

aPriori previously released the ability to automatically align the source (net shape) model to the finished machined model when the global co-ordinate systems were different. aPriori 2025 R1 SP2 provides some improvements to the auto alignment to address specific issues reported by customers occurring in a small subset of part types.

-

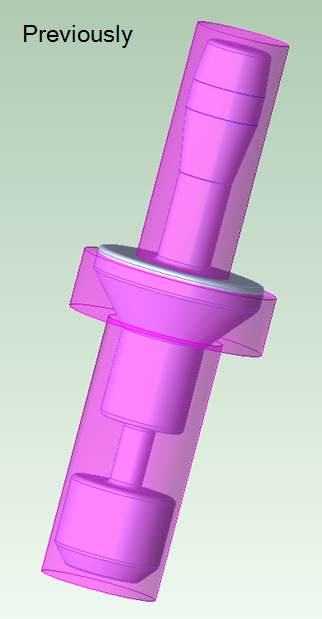

Previously for some parts, the machined part was shifted in the axial direction, so that features of the turned part such as flanges were not completely enclosed within the net shape part. The example below shows previous behavior and the improved alignment in this release:

-

This release also fixed an issue where aPriori identified the machined model as lying outside the source model, when in reality the machined model surface lay exactly on the source model. This fix reduces erroneous warnings to the end user concerning the accuracy of the machined model.

Use of 2-Model Machined Parts in Matrix Costing and Bulk Costing

aPriori 2025 R1 SP2 resolves an issue that prevented 2-Model machined parts from being analyzed with the Matrix Costing or Bulk Costing modules.

Note this issue affected releases of aPriori 2024 R1 SP1 through aPriori 2025 R1 SP1, not earlier releases.

In this latest release, once you have successfully analyzed a 2-Model Machining scenario, you can once again leverage Matrix Costing to successfully cost multiple variations of the 2-Model Machining scenario.

Similarly, you once again can leverage bulk costing to analyze multiple variations of the 2-Model Machining scenario, by selecting the Cost > Cost Scenario workflow. This launches a bulk costing window which allows you to define and analyze additional scenarios as needed.