Quoting Tutorials

Use aPriori to effectively and efficiently generate consistent and profitable quotes.

Note: You should have a basic level of proficiency in using aPriori products, including aPriori Documentation Version 2025 R1 SP2 and aP Analytics, to make full use of these tutorials. See the aPriori Academy training course catalog to access training on these areas.

Introduction to Quoting

If your company manufactures components to sell as products to other companies, you can use aPriori's formulaic approach to estimate product costs in a consistent and automated way, to increase throughput, provide consistency, and reduce your risk of negative margins.

-

For new quote packages, use aPriori to provide quotes quickly, ensure your quote is competitive, and minimize your risk.

-

For your existing business portfolio, use aPriori to ensure it remains profitable when there are sudden changes to your cost structure, spikes in material costs, or spikes in inflation due to factors such as labor and OH cost changes.

Estimates are “bottom-up,” starting at the lowest level of components in each product, then working up to sub-assemblies and assemblies, then finishing with a full, detailed product estimate.

Formulaic Approach

aPriori products take a formulaic approach to creating estimates. Using expert manufacturing knowledge and data, we create cost estimates for each component, based on predefined standard manufacturing practices and characteristics. Using your customer’s CAD file, aP Pro extracts all the relevant geometry, features, and tolerances, then creates an optimum routing process based on your factory’s manufacturing equipment.

After you review and accept this routing, aPriori estimates the cycle time for each process step, and the gross amount of material needed to make the component. Based on those results, it estimates the cost by converting cycle time and gross mass into a currency amount such as dollars, using your predefined labor, overhead, and material costs.

See Review Analysis Results for more details.

Example

To manufacture a 1.5 mm sheet metal component with many small internal holes and no-large curvatures, aPriori may initially select a turret press over a CO2 laser to cut the part. However, if your factory does not have a turret press, aPriori selects another suitable cutting process, such as a fiber laser. If your factory only has plasma cutters, aPriori fails the component manufacture and informs you that you cannot use a plasma cutter without damaging the component.

Additionally, aPriori recognizes when holes are too close to a bend or are too small to be punched for risk of breaking the pin, and automatically adds a drilling operation for such holes, or adds a 3D laser if that is a cheaper routing.

Configuration Using Digital Factories

You can define and configure factors such as specific manufacturing rules, limits, or routings in a Digital Factory, which is a virtual model of your physical factory. Use the Digital Factory Manager for these functions.

Note: You can accept aPriori's default manufacturing rules, machines and capabilities without any edits, if these fit your requirements.

See the Digital Factory Administration Guide for more details.

To properly simulate manufacturing processes and costs at your factory, configure these common items:

-

Machine list, including machine parameters, purchase price, depreciation status, and expected lifespan.

-

Capabilities of such machines, such as sizes, speeds, and tonnage, so that aPriori can determine which machines are best for each component.

-

Material list and negotiated material rates.

-

You can provide us with the associated labor and overhead (OH) rates for each machine, or aPriori can calculate overheads based on values like

-

Number of shifts per day

-

Number of hours per shift

-

Number of working days per year

-

Selling, General, and Administrative (SG&A) rates

-

-

Desired profit mark-up rates

-

Any specific manufacturing practices that you want to include - for example, “never use a turret press for parts thicker than 3.25mm”.

Having this intimate knowledge of your factory equipment and practices allows aPriori to closely simulate component as it moves through your manufacturing process.

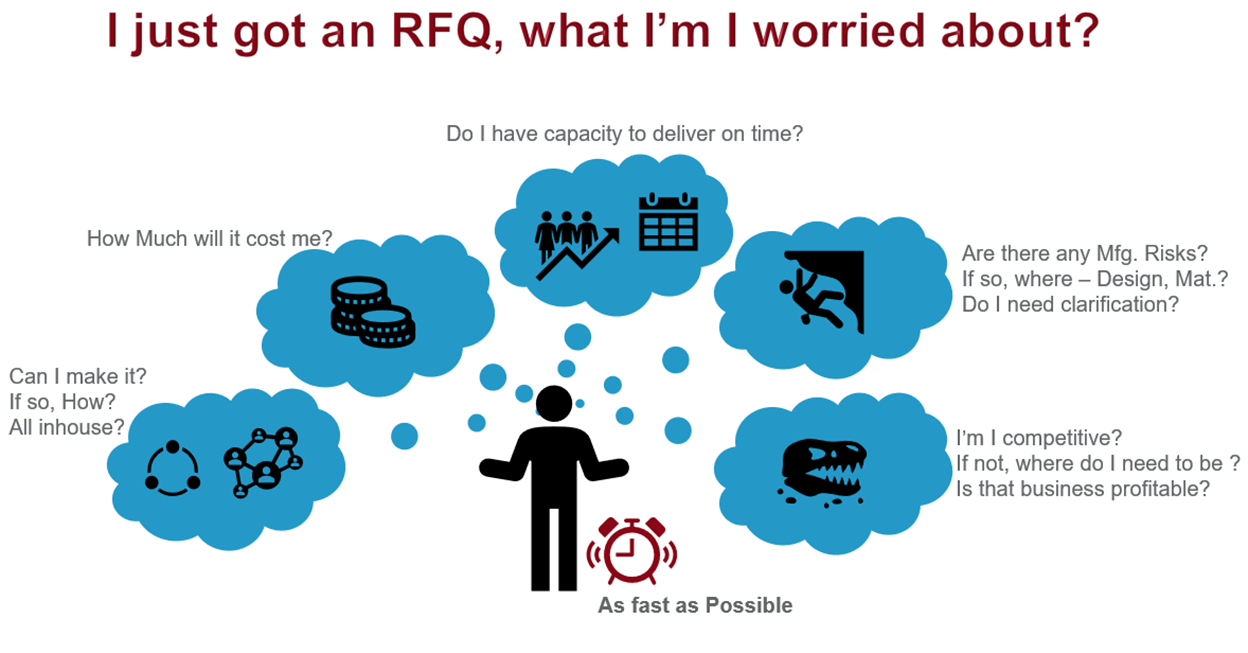

Addressing Common Questions

Typically, when your company receives a Request For Quotation (RFQ), you need to answer some specific questions:

The following tutorials provide answers to these questions.