Sourcing Tutorials

Introduction

If you are new to aPriori, you should complete a basic training course before you continue, accessible to all users from aP Academy.

These tutorials describe multiple examples of stand-alone analysis with aPriori, to match your specific buying behavior and practices.

aPriori can help make your sourcing process more efficient and more effective for all ranges of component purchases, from high-mix, low volumes to component orders in the tens of thousands.

-

More efficient: Identify which components have the greatest potential savings, so that you can prioritize your efforts, avoiding attempting to negotiate fairly-priced components. Identify which suppliers are best suited to make your components, and help group components to create bid packages that can be quoted optimally

-

More effective: Provide detailed manufacturing and cost information about your components to identify differences between your quote and supplier estimates. Use this information to negotiate more effectively with suppliers to resolve such differences, which leads to savings. Also help reduce common supply chain risks.

Getting Started

Before using any of these tutorials, you should gather the data you need, and run an initial analysis (cost).

Step 1: Gather Data

First, use aPriori analysis tools to identify components with the most savings opportunities. As a general practice, we suggest you:

-

Identify components with both high forecast production volume and high total cost, where even a small saving would justify the negotiation effort.

-

Ensure there are no commercial or legal reasons blocking renegotiation or re-sourcing, such as contractual obligations or sensitive supplier relations.

Step 2: Analyze Components

Next, select the components for analysis based on the highest spenders, then group the components by process and analyze (cost) the components in aPriori (see Analyze a Component), using all the information a supplier would need for a quote, including the CAD file, 2D drawing, and approximate production volume.

Note: aPriori analysis will only give accurate quotes if you provide all the relevant information. Although aPriori can import all the geometry from the 3D CAD file, you may need to provide additional information, such as: is the part painted? Are there any tolerances that are not on the model? Is the part heat-treated?

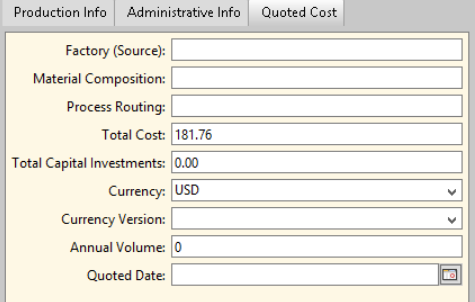

Enter your current cost quote, using the Cost Object Info window > Quoted Cost:

Tip: You can also use the aPriori BOM loader to load costs from your ERP/Sourcing system into aPriori. See BOM Loader.

Step 3: Group Components by Process

-

If the components are already analyzed in aPriori, create roll-ups with the above groupings (see Using Roll-ups).

-

If the components are not costed, place the CAD files of the groups in individual folders for each grouping, then use bulk costing to cost them (see Bulk Costing and Analysis).

Note: Ensure you set the bulk costing tool to create roll-ups automatically.

Alternatively, you can analyze each component separately, or use aP Pro Deep Costing functions. See Deep Costing.