Note: the Bulk Costing and Analysis module requires a separate license.

Introduction to Bulk Costing and Analysis

Use Bulk Costing and Analysis to quickly analyze multiple components at the same time, uploading these components from a directory in a single bulk operation. Bulk costing also allows you to see your data together in a roll-up for easier and more intensive analysis.

This allows you to quickly identify cost-reduction opportunities for groups of components, by identifying outliers, where aP Pro-generated "should cost" values are significantly lower than real-world cost quotes for specific components.

You can also use Bulk Costing to specify different scenarios and compare their costs. For example, you can compare production costs in different regions, countries, and volumes.

Tip: See also the Introduction to Bulk Costing and Perform Bulk and Matrix Costing aP Academy training courses.

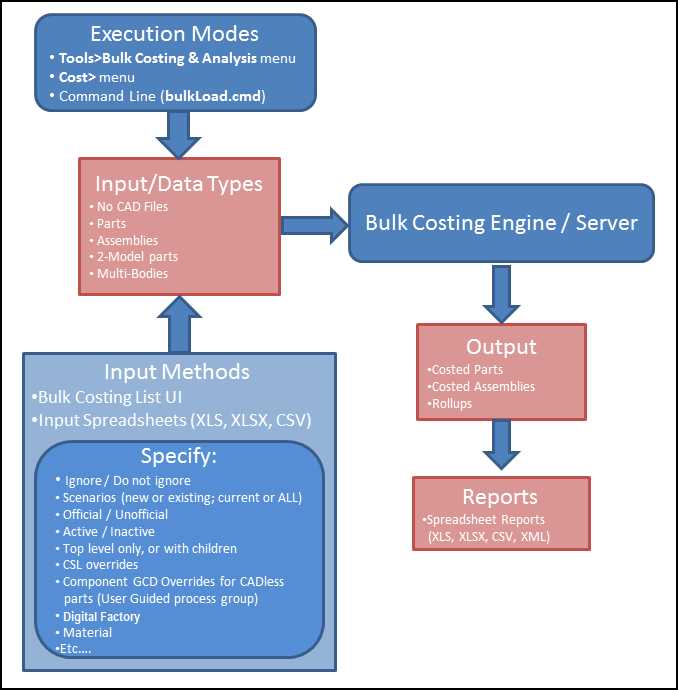

Process Overview

You can quickly generate preliminary costs for groups of parts, by setting their initial costing parameters using a tabular interface, then bulk costing:

Bulk costing creates a Roll-Up for further analysis and review. See Roll-ups.

Run Bulk Costing

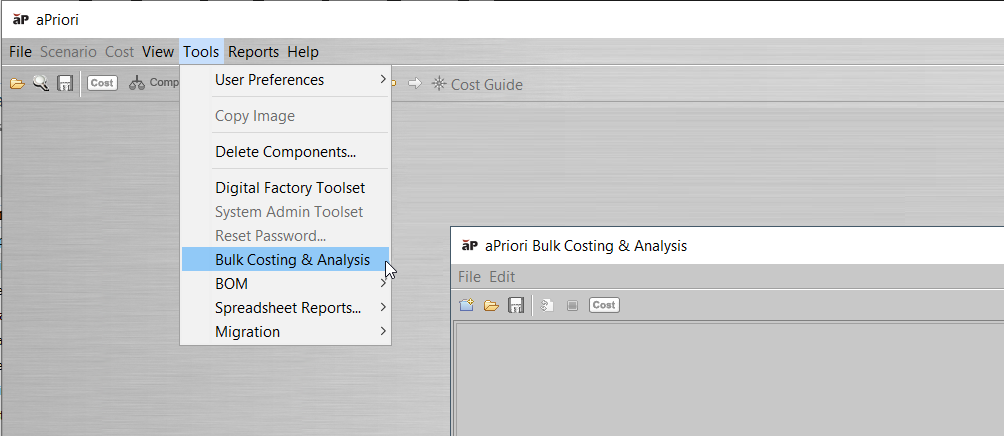

Select Tools > Bulk Costing & Analysis to display the Bulk Costing & Analysis window.

See Bulk Costing Using the UI and Bulk Costing Menu Commands.

After setting inputs, you can then cost (analyze) the components in this bulk cost group. See Costing a bulk cost group.

Alternative methods to run Bulk Costing

-

Bulk costing also allows you to take data from a spreadsheet; for example, to define all production inputs, add secondary processes, and override PSOs. See Supply Bulk Costing Data from a Spreadsheet.

-

You can also run bulk costing from the command line, using CSV or Excel content for input. See Running from the Command Line.

Bulk Costing or Deep Costing?

Bulk Costing provides enhanced functionality compared to Deep Costing.

Deep costing helps you quickly cost components in a single assembly, but Bulk Costing allows you to cost any combination of components and assemblies, allows you to edit a wider range of production information values, and also allows you to make use of Input Sheets.