You can copy the cost setting from a component to another component.

-

Copy the cost settings from another costed component when you use aPriori to cost a part defined by a CAD file, then change the CAD filename. Copy the cost settings to avoid losing any costing changes you made when aPriori was referencing the previous file name.

-

You may also want to copy the cost settings from another component to speed up costing for parts that are identical or very like previously costed parts. For example, if a component changed a part name or number, copying the cost settings enables you to avoid manually re-specifying all the cost inputs for that component.

-

You also have the option of copying either a single scenario or all scenarios from one component to another.

-

You can also copy some or all the cost settings for an assembly to each of the assembly’s children. See Copy Assembly Inputs to Children

Copying cost settings from a costed component

-

Select Edit > Production Info from the Manufacturing Process pane to display the Production Info window.

-

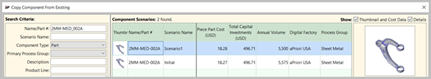

Click Copy From to display the Copy Component From Existing window.

You can also click Copy From on the Cost Object for an uncosted component. In an assembly, select an uncosted component in the component viewer or Geometric Cost Drivers pane, right-click it, and select Initialize from the context menu to display the Production Info window.

-

Search for the donor component that contains the cost settings you want to copy. For more information, see Using the Search tool.

- To copy a single scenario, if the component has more than one scenario, select the scenario.

- Click OK to re-cost the recipient component using the cost settings copied from the donor component.

- When you copy cost settings from another costed component, aPriori maps GCDs and GCD settings from the donor component to the recipient component. Any GCDs that aPriori cannot map to the recipient component’s geometry are discarded. aPriori then creates new GCDs for the recipient component geometry.

- The GCD mapping works best for highly similar or identical parts, but aPriori recommends that you confirm the correct mapping for all manually applied GCD settings by checking your green user/input indicators.

- Copied information includes component-level settings such as process group, annual volume, Digital Factory, and manually selected routings and GCD-level settings such as tolerance and roughness settings or manually selected operation sequences.

- If the component in aPriori is not connected to a CAD file, aPriori copies all the donor component settings to the recipient component, including the appearance of the donor component. Once you connect the recipient component to a CAD file, its GCDs automatically update to match the CAD file’s geometry.