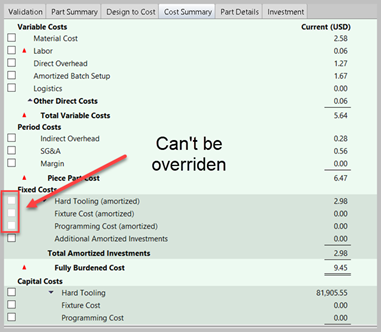

Use cost summary overrides to override costs in the Cost Summary tab, such as Material Cost or Logistics. These reflect costs for the entire routing used to create the component, rather than costs for any individual process or operation.

Override Cost Summary Values

To override individual Cost Summary values for a part or assembly:

-

Click the

icon or select Scenario > Enable Cost Overrides. In the Cost Summary table, you see check boxes for each value; checkboxes with a black border are editable values.

icon or select Scenario > Enable Cost Overrides. In the Cost Summary table, you see check boxes for each value; checkboxes with a black border are editable values.

-

Select a check box for each cost value that you want to edit.

-

Enter a new value, overriding the previous value. The cost totals associated with the value automatically re-calculate.

-

You can enter a note about the purpose or contents of the override in the Comment window that appears. After you have entered a comment for a cost override value, a small red triangle appears in the upper right of the cell. You can click on that triangle to view or edit the comment in the future.

-

Click Save .

Note: In general, you cannot override amortized values, but you can override the Capital Costs fields, and these values are amortized and reflected in the Fixed Costs fields.

Notes

-

The cost value that has been checked for manual costing is no longer affected by changes to the component’s GCDs, non-geometric cost drivers, or Digital Factory data. To reverse this, Reset Overrides.

-

You can use cost overrides for cost values that can be calculated by aPriori as well as for those that aPriori does not consider. For example, the material used to fabricate a part may require a special vendor-supplied finish or processing that is not reflected in the cost of the material stock specified in the Digital Factory. In this case, you can override the material cost for this part to reflect the cost of material with the required finish. Alternatively, you may wish to override the material unit cost, which is used to compute the total material cost, using the Material Selection window. For more information, see Chang material unit cost.

-

You can also use cost overrides to include the logistic cost to fabricate a component, such as internal or external shipping and handling, since by default, aP Pro does not compute logistics costs but does provide a Logistics field in the cost taxonomy.

Reset Overrides

-

Click the

button or select Scenario > Enable Cost Overrides. aPriori discards the manually specified values, re-evaluates the CAD geometry, and computes the cost values for the component.

button or select Scenario > Enable Cost Overrides. aPriori discards the manually specified values, re-evaluates the CAD geometry, and computes the cost values for the component.

-

Click Save .

Total cost summary overrides

You can specify all cost summary values for a part or assembly. Manually costed components are typically used when the cost for the component is not determined by its geometry or production facility. For example, you may design a CAD model for a part that is sourced from a supplier. In this case, the cost for the part is determined by the supplier and manually entered in aP Pro.

Note: While the GCDs and Manufacturing Process information do not impact the cost for a manually costed component, they can impact the process level costs when that component is used in an assembly.

Create a Manually Costed Component

-

Open a component (part or assembly).

-

Select Scenario > Manually Costed. Editable fields in the Cost Outputs pane change color, indicating that all costs are specified manually and are not affected by changes to the components GCDs, non-geometric cost drivers, or Digital Factory data

-

For each field you want to edit, enter a new value and press Enter or move to another field. The cost totals associated with the value automatically re-calculate.

-

Click Save .

Convert a Manually Costed Component to aP Pro Costed

-

Open a manually costed part or assembly.

-

Select Scenario > Manually Costed. aPriori discards the manually specified values, re-evaluates the CAD geometry and computes the cost values for the component.

-

Click Save.

Precedence of production input overrides

aP Pro enables you to set and override production inputs in several ways. Production inputs include settings such as Process Group, Digital Factory, Material, Annual Volume, and Batch Size.

The following is the precedence aP Pro follows for production inputs, in descending order:

-

4: User Override, if specified. For example, manually entering a value in the Cost Guide (see Analyze Components with the Cost Guide), or providing a value on the input spreadsheet or via the UI for Bulk Costing (see Bulk Costing and Analysis). User overrides always win.

-

3: CAD Property value, if provided. For more information, see Costing using CAD properties.

-

2: Preference value from Tools > User Preferences > Default Production Inputs….

-

1: Site or Digital Factory default, if specified. This used if none of the above apply.