Costing with a Mix of Standard and Engineered Components

This section provides and example of bulk costing an assembly that has a mix of standard commercial, off-the-shelf (COTS) components and new engineered components. The desired behavior is for the assembly scenario to include the pre-existing, official scenarios and corresponding costs of these standard components, rather than creating and costing new scenarios.

Tip: See also the Cost Hardware Parts aP Academy training course.

Consider an example flange coupling assembly that consists of the following parts and quantities:

-

p01_Flange – quantity 2

-

p02_Shaft – quantity 2

-

p03_Key – quantity 2

-

p04_Bolt– quantity 4

-

p05_Nut – quantity 2

|

|

|

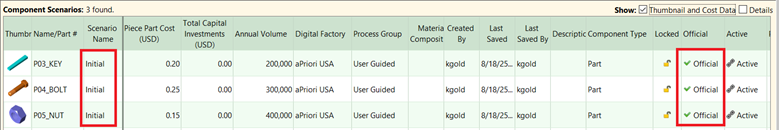

| p03_Key | p04_Bolt | p05_Nut |

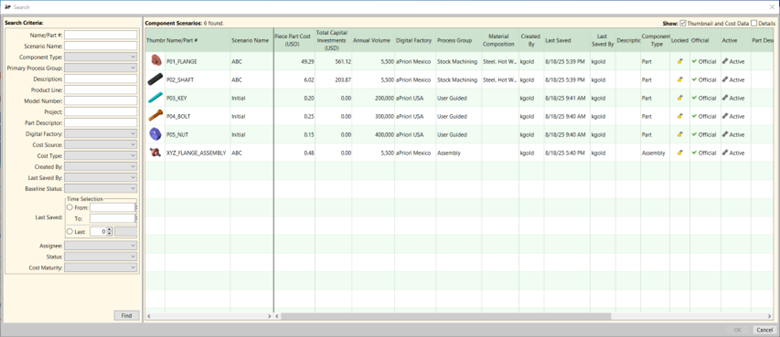

The flange and the shaft parts represent newly-designed parts that have not yet been analyzed in aPriori. The key, the bolt, and the nut represent standard COTS components that have an approved, official cost. These components were previously loaded into the aPriori database as “manually costed” components with the specified cost, and the scenario name “Initial”. These Initial scenarios were designated as the “official” scenarios for these components. You can view those official scenarios by using the Scenario Search dialog (File > Open Scenario). The Official column in the search results indicates whether each scenario is official.

When you cost the flange assembly, the desired behavior is to create a new assembly scenario which includes new scenarios for the flange and the shaft parts, but includes the pre-existing official scenarios of the key, bolt, and nut.

To achieve this with interactive Bulk Costing, select Tools > Bulk Costing & Analysis from the main aPriori screen. When the Bulk Costing & Analysis screen appears, select File > New Bulk Cost Group.

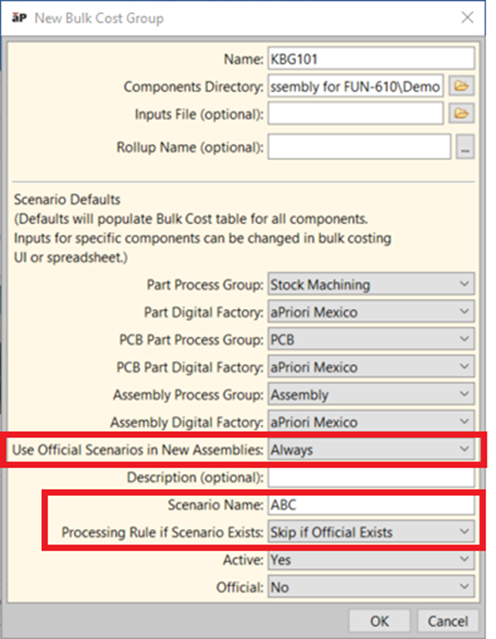

When the New Bulk Cost Group dialog appears:

-

Set the Components Directory to the location of a folder that contains the CAD models of the assembly and its parts.

-

Specify a Scenario Name for the new assembly scenario and any new subcomponent scenarios that get created as part of this bulk costing—in this example we use ABC.

-

Set the option Use Official Scenarios in New Assemblies to Always.

-

Set the option Processing Rule if Scenario Exists to Skip if Official Exists.

-

Set other defaults such as Process Group and Digital Factory choices as appropriate—in this example, we use the Stock Machining process group and the aPriori USA Digital Factory.

-

Click OK.

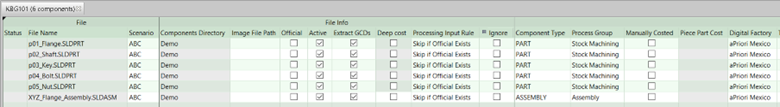

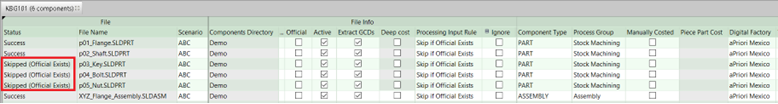

The Bulk Costing table will appear, with six rows populated for the assembly and each of the 5 parts in the assembly. The Processing Input Rule is set to Skip if Official Exists for all rows, because this was specified as the default value.

If desired, before proceeding with the analysis, you can adjust the Processing Input Rule or any other input field, for any row/component in the table. In this example, we will just click Cost.

When the Bulk Costing run completes, the Status column indicates that the assembly, flange, and shaft were costed successfully, but the key, bolt, and nut were skipped, because an official scenario was found for each of these components.

In the Scenario Search dialog, you can confirm that scenarios named ABC were created for the assembly, the flange, and the shaft, but not for the key, bolt, or nut:

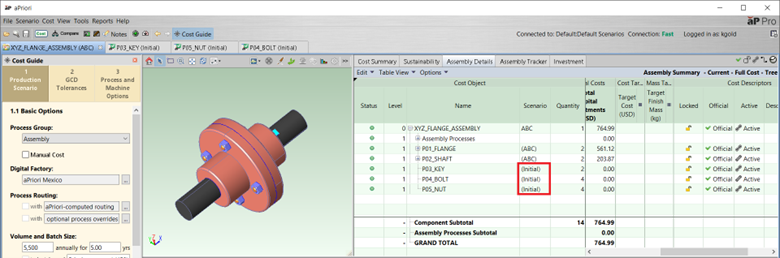

And now, if you open the assembly scenario itself, it includes the newly-created ABC scenarios for the flange and the shaft parts, and the pre-existing “Initial” scenarios of the key, bolt, and nut, representing the approved cost for these standard components.

Note that while the example above was conducted by interactively using the Bulk Costing & Analysis module in the aP Pro UI, you also can run Bulk Costing & Analysis from the command line and supply these same inputs. Some aPriori customers have built sophisticated automated workflows to analyze large numbers of parts in aPriori. This involves programmatically generating part-specific inputs based on PLM or CAD metadata or other sources of information, writing these inputs to a Bulk Costing input spreadsheet, and initiating the Bulk Costing module via the command-line interface.