Analyze Assemblies

aP Pro provides specific features to import, analyze (cost) and review results for assemblies, containing multiple sub-components (parts or sub-assemblies).

Note: These assembly-specific features are in addition to the standard features to Analyze a Component and Review Analysis Results.

Process Overview

Tip: Also see Example Assembly.

Open an Assembly

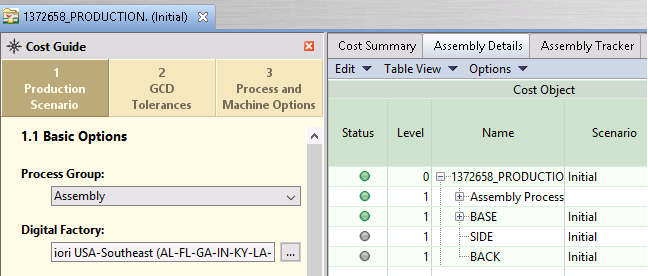

When you first open a CAD file for an assembly, aP Pro automatically recognizes that the component is an assembly, and selects the Assembly process group by default.

See Open a Scenario for more details.

Note: You will not see the assembly structure initially. To see this structure, you must first analyze(cost) the assembly.

Run Assembly Analysis

Next, analyze (cost) an assembly; either:

-

Deep Costing: analyze an assembly and its sub-components in a single operation. Typically best for larger assemblies that require less component-level configuration.

-

Analyze a Component: analyze each assembly component individually, using standard part analysis functions. Typically best for small assemblies with few parts.

Tip: If you have analyzed the top-level assembly, you can then use the Initialize option to analyze the sub-components in that assembly. See Analyze Sub-Components Using the Initialize Option.

Review Results

After you analyze an assembly, you can view analysis results in Assembly Details and Assembly Tracker tabs, and make edits using these and other functions.