You can import and export scenarios from one aPriori database to another, as .ap files. Scenario data includes all the cost and GCD information for that component (parts, assemblies, or roll-ups).

Tip: To export a large number of parts at, first add them to a roll-up, then export that roll-up.

This data-sharing capability enables manufacturers to collaborate with their suppliers and other third parties, such as consultants, who are supporting their design and sourcing activities.

Export a Scenario

You can export the current scenario, or search and select a scenario to export.

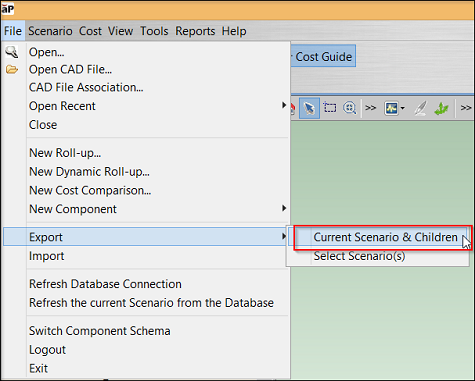

To export the currently-open scenario, plus any children belonging to that scenario:

-

Select File >Export > Current Scenario & Children

-

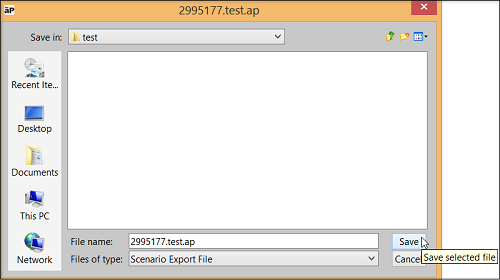

Choose a location and name for the exported file, then click Save:

Note: Exporting the current scenarios will include any unsaved modifications.

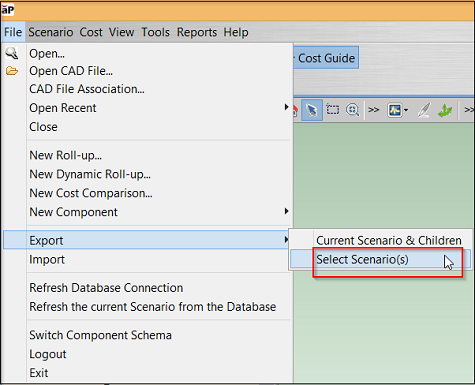

To export a different saved scenario:

-

Select File > Export > Select Scenario(s):

-

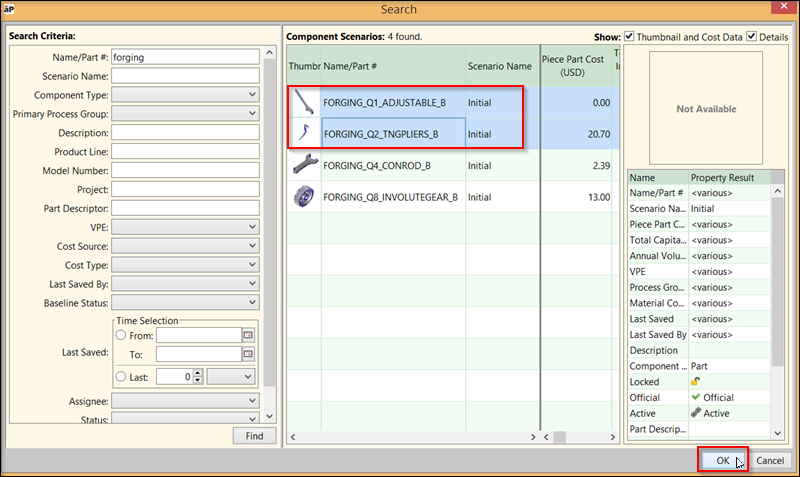

Use the search window to find and select all of the components to export, then click OK:

-

Choose a location and name for the exported file, then click Save.

Note: Exporting assemblies also exports all the scenarios the assembly relies on. Exporting roll-ups also exports all the scenarios in the roll-up.

Import a Scenario

To import a saved scenario into your aP Pro system:

-

Select File > Import.

-

Navigate to the .ap file containing the scenario to import and click Open.

-

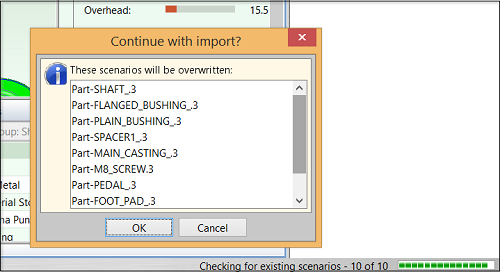

If any of the part number/scenario combinations already exist in the database, the list of parts which do already exist are displayed.

If you click OK, the import will proceed, overwriting existing parts. (regardless if they are locked or unlocked).

-

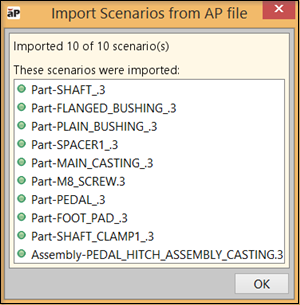

A window opens showing whether the import was successful and which scenarios were imported:

Import Overwrite Example

If part 123456.initial exists in the database and is the only scenario for part number 123456, and 123456.India is imported. Scenario 123456.initial remains and 123456.india is added. If 123456.India was official when it was exported, it becomes the official scenario when it is imported.

Therefore, when a user in India costs a sub-assembly, they must export the .initial scenario so that its cost pulled into the higher-level assembly. If that sub-assembly already exists in the US it is overwritten upon import.

Basic workflow for sharing data

The following example explains the workflow between two sites of the same manufacturing company or between a manufacturer and their contract engineering firm. For the purposes of this explanation, it is assumed that the Manufacturer is in the US and the Contract Engineering Firm is in India.

-

An engineer in the US initiates a work order for costing a set of parts. This is typically 10 -50 parts but might be up to 100.

-

An engineer in India executes the work order by costing the parts in aPriori.

-

The engineer saves each part as a new scenario, gives the scenario a unique name, and makes the scenario ‘official’.

-

On a periodic basis, or when the work order is completed, the engineer in India creates a rollup and adds all the scenarios in the work order into the rollup.

-

-

The engineer in India exports the rollup from aPriori to create a file on disk.

-

The exported file is shared and made available to users in the US.

-

A user in the US imports the file using aPriori.

Notes about the workflow

-

The naming convention is determined by the aPriori customer so as it does not overwrite data in the US database if the part already exists there (unless that is the desired behavior). The scenario name must not contain a colon (:).

-

The timing of the export is determined by the aPriori customer. When you add parts to the rollup, parts can be added using criteria such as date range, Digital Factory, or the user ID of the person who last saved the part.

-

There is a practical limit to the number of parts that can be placed in a rollup and exported.

-

The exact number depends on the computer being used and the complexity of the parts in the rollup.

-

On a typical 32-bit workstation, it should handle 100 parts without issues.

-

Use a 64-bit workstation and more memory to increase the number of parts you can place in a rollup.

-

-

The file transfer mechanism works in either direction. For example, users in the US makes changes to a part, export it, and the India user can import it.