Materials show the name of the chemical composition or alloy from which a part is made.

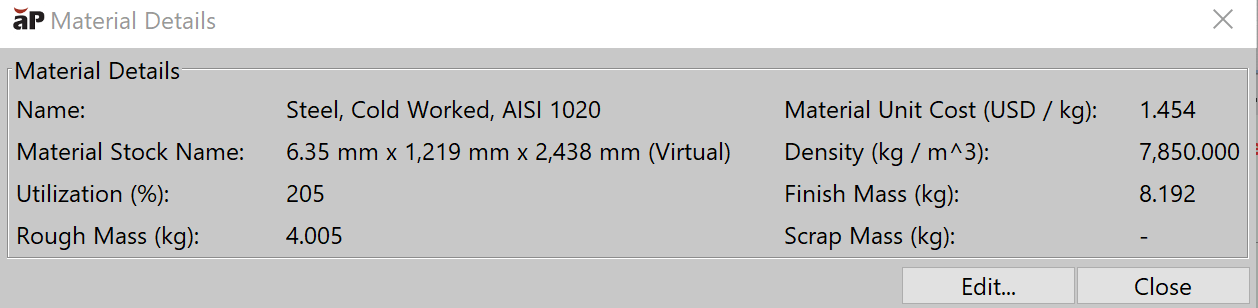

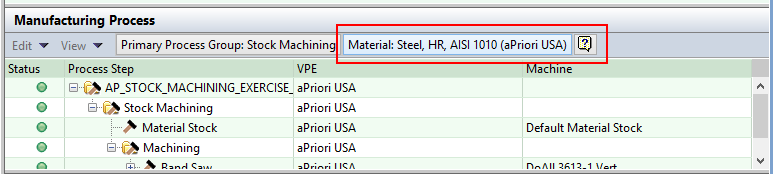

To view material details, in the Manufacturing Process pane, click the  icon next to the Material button to open the Material Details dialog box.

icon next to the Material button to open the Material Details dialog box.

To edit material details, either click the Edit... button from this window, or click the Material field to open the Material Selection window.

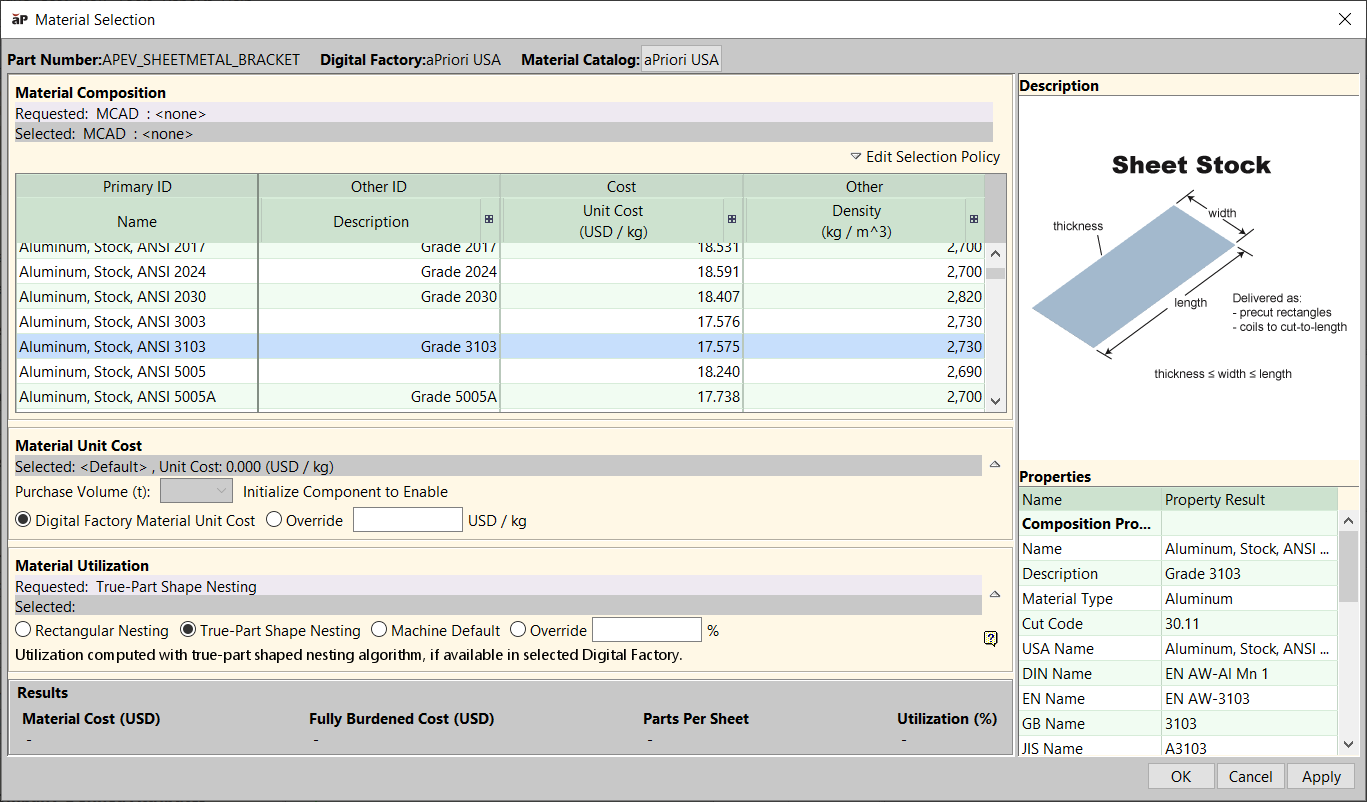

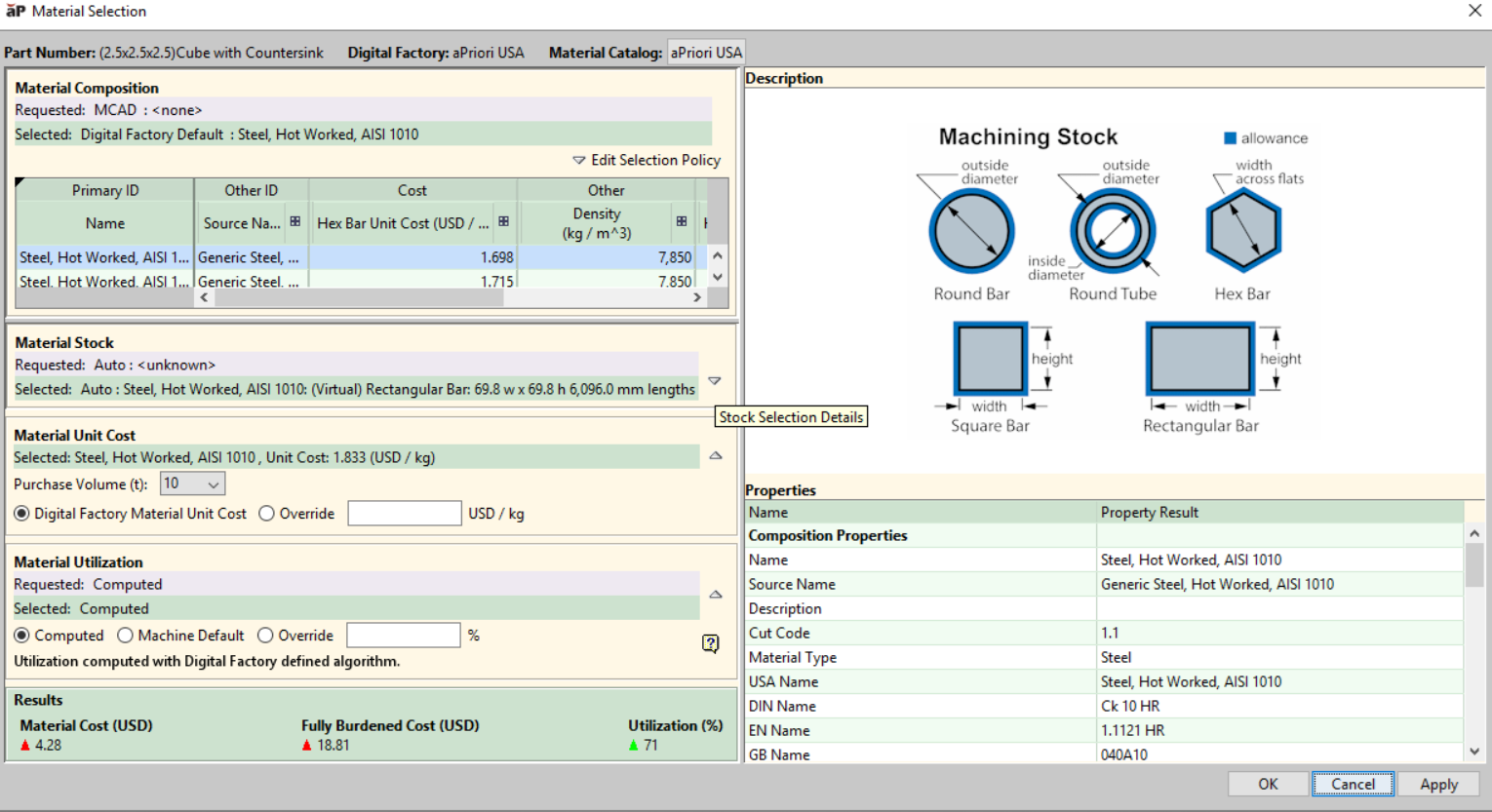

- The Part Number and Digital Factory selected for this part are displayed in the window header.

- The list of materials shows all the materials available for the selected Digital Factory.

- Material automatically selected by aPriori is highlighted and the related properties are displayed in the Properties list.

- The Description panel shows material stock size and form.

- An overall results status indicator in the Results area shows the costing status of the input:

- Green: Costing completed with the requested input.

- Yellow: Costing completed with warnings. Typically, indicates that the requested input was invalid, based on selection policy used.

- Red: Costing failed, with warnings in the Status Messages pane.

Separate status indicators also appear for Material Composition and Material Stock

Edit Material Information

You can make changes to the values in the Material Selection window, then:

-

Click OK to apply changes, recalculate the cost, and close the Material Selection window.

-

Click Apply to apply changes and recalculate the cost, staying in the Material Selection window.

Change Material Catalog

By default, the current material catalog is the catalog associated with the current Digital Factory.

To change this association, click the button next to the label Material Catalog.

You can then select the Digital Factory associated with the desired catalog, then click OK to return to the Material Selection window.

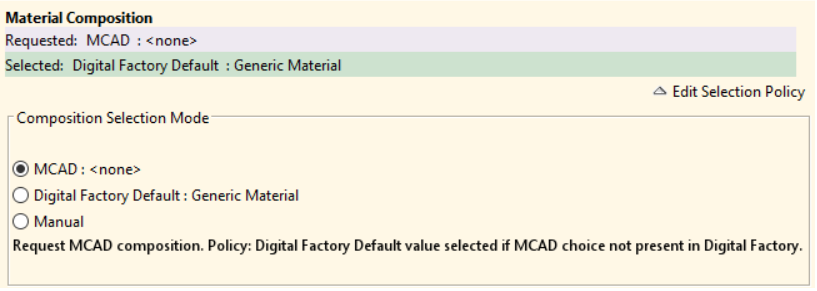

Change Selection Policy

The selection policy describes how the material selection input is provided.

-

Click Edit Selection Policy to view or change the source for material selection:

- Select:

- MCAD: The default, default source, showing the material specified by the CAD system. If not provided or available, the Digital Factory Default material is selected.

- Digital Factory Default: The default material defined for that Digital Factory. See the aPriori Administrator Guide.

- Manual: Material selected manually by you. The Digital Factory default is selected if your specified choice cannot be costed.

- The selected choice appears in the Requested field.

Select Material

-

Select a material from the list. This changes the selection policy to Manual.

-

The Selected field shows the selection policy and the selected material.

Change Material Stock.

-

In the Manufacturing Process window, click on the material label:

-

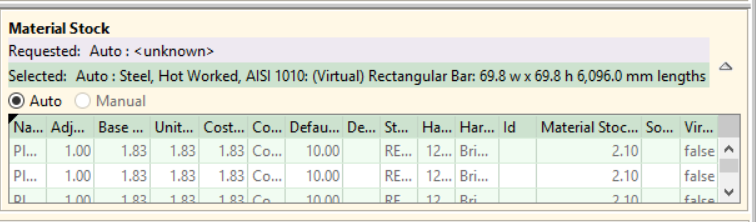

In the Material Selection window that appears, navigate to the Material Stock section:

-

This panel shows the following information:

-

Requested: The requested stock source: Auto, Manual, or Custom Cut.

-

Selected: The presently selected stock.

-

-

Click the button on the right side of the Material Stock panel to expand this panel.

- Select a material stock mode.

- Auto: (default) aP Pro selects the material stock, using a stock algorithm which depends on geometry constraints, material utilization, machine selection, and routing selection. If no valid stock is available, aP Pro computes the cost with virtual stock. The stock selection rules are defined in the Digital Factory selected - for example, selecting the smallest stock that is possible for this part.

Manual: Select a different material stock from the list of material stock available for the selected material composition. For example, changing the stock size.

Note: You can only select Manual for any stocks that are within the "snap" window for the Digital Factory. Consult your Digital Factory manager for details of changing this window.

Custom Cut: Available for Bar & Tube Fabrication parts only, you specify a custom stock length, either by specifying the total length or indicating size-to-fit with a specified trim allowance.

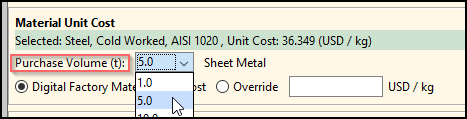

Change Material Purchase Volume

Purchase volume affects material cost - see Working with Material Factors. After you run an initial costing analysis, you can then set material purchase volume for a part (the initial costing assumes the default purchase volume for the current material and process group).

To change the purchase volume, in the Purchase Volume dropdown list, select a value from a list of all available purchase volumes (in metric or imperial tons) for the current material and process group.

Note: Specifying or changing material, stock form, or stock can change the default purchase volume as well as the available purchase volumes.

Change Material Unit Cost

The Material Unit Cost panel shows the unit cost (cost per mass) of the selected material composition / stock. By default, aP Pro uses the unit cost value defined in the Digital Factory for the current material values. You can can override the unit cost value; for example, if current material prices have changed significantly

- To override material unit costs for the current part, select the Override radio button and enter the new material unit cost (take care to note the units).

-

To revert to using the value specified in the Digital Factory, click the Digital Factory Material Unit Cost radio button.

Change Material Utilization

The Material Utilization panel shows the selected utilization mode.

- Select the material utilization mode:

- Computed: aPriori computes utilization with a defined algorithm. The algorithm used varies by process group; more in the aPriori Cost Model Guide.

Machine Default: aP Pro uses the selected machine’s default utilization value.

Override: Specify the material utilization value in the % field. If you selected Override, enter the value in the % field.