aPriori now provides design guidance for two more commodity types and improves the usability of the feedback as described below:

- New Design Guidance for Bar & Tube Fabrication

- Increased availability, usefulness, and configurability of Validation tab

-

Improved Naming and Organization of Design for Manufacturability and Cost Issues

New Design Guidance for Bar & Tube Fabrication

aPriori 2022 R1 provides Design For Manufacture and Design To Cost feedback for parts made from standard bar and tube stock forms in the Bar & Tube Fabrication process group.

aPriori now detects and alerts the user to various manufacturability and cost-driving design issues for parts fabricated from standard commodity stock forms (e.g. round bars and tubes, square bars and tubes, hex bars, etc.) Specifically, feedback is provided for parts that include bending processes and expansion forming. A summary of this new DFM and DTC feedback can be seen below. Items marked with an asterisk also are used as operation feasibility rules.

- Limit Number of Unique Bend Radii - the number of unique bend radii should be kept to a minimum, to reduce the number of separate die stacks required and therefore tooling cost.

- Minimum Distance between Bends - the minimum distance between bends should be at least 2x the width of the stock, to minimize distortion and the need for specialized tooling.

- Minimum Centerline Radius - the minimum centerline radius should be at least 5x the width of the stock (for Profile 3 Roll Bending and Rotary Draw Bending), and 4x the stock width (for Compression Bending), to avoid wrinkling and distortion.

- Tube Bending Difficulty Factor (Compression Bending) - assesses the complexity of tooling required to complete the bend, and advises how it can be reduced by adjusting the values of centerline radius, outer diameter/dimension, and wall thickness.

- Max Allowable Bend Elongation* - the elongation on the outside of the bend should not exceed the max allowable elongation for the chosen material, to avoid thinning or tearing of the material.

- Max Allowable Form Elongation* - the elongation on expanded section of the tube should not exceed the max allowable elongation for the chosen material, to avoid thinning or tearing of the material.

Note: These metrics are available by default for the latest version of the Bar & Tube Fabrication cost model that is co-released with aPriori 2022 R1. Older cost model versions also may be configured to provide this design guidance if desired. Contact your aPriori account representative for more information.

Design Guidance for Compression Molding

aPriori 2022 R1 provides a new manufacturing process cost model for Compression Molding, which includes Design For Manufacture and Design To Cost feedback in addition to manufacturing process and cost estimation.

The following design guidance for parts made by compression molding:

- High Thickness Variation - the max thickness should not be greater than 3 times the thickness of the majority of the part

- High Required Press Force - the max thickness of the part should not be greater than 1 inch or 25.4mm

- Die Lock Condition - there should not be an undercut feature that creates a die lock condition

- No Cost Undercut - undercut features that require the part to flex to be removed from the tool should be removed or kept to a minimum

- Inaccessible Void - internal undercut features are inaccessible and cannot be molded

- Feature Requires Machining - through features that are not in the draw direction require machining

- Simple Hole is Machined - Simple Holes that are aligned with the draw direction are machined but may be molded to save cost

- Mold Plating - the least expensive mold plating that gives the fewest number of tools over the lifetime of the part should be selected

- Capped Internal Cutouts - internal Cutouts should not be capped if the area of the cutout is large enough that it has a significant negative impact on the utilization

- Cavity Texture - adding cavity texture adds cost and should be kept simple or removed where it is not strictly necessary

- Cavity Finish - adding cavity finish adds cost and should be kept simple or removed where it is not strictly necessary

- Mold Closure Type - using a Positive Mold Closure Type is costly and should only be used where strictly necessary

- Manually Inserted Components - adding manually inserted components adds to cost and cycle time and should be kept to a minimum where possible

In addition, the following feedback already was provided for previously-available processes in the Plastic Molding Process Group and now also are provided for Compression Molding parts.

- Maximum Wall Thickness

- Minimum Wall Thickness

- Hole Proximity

- Hole Depth to Hole Diameter Ratio

- Blind Hole

- Draft Angle

- Minimum Edge Radius on Parting Line

- Minimum External Edge Radius

- Minimum Internal Edge Radius

Increased availability, usefulness, and configurability of Validation tab

aPriori now displays a Validation tab for all process groups. The purpose of this tab is to display key assumptions of the aPriori analysis. Users should confirm these assumptions are correct, and modify them if needed, before reviewing the manufacturing and cost estimates in detail.

The following process groups previously did not display a Validation tab but now will in aPriori 2022 R1:

- Additive Manufacturing

- Bar & Tube Fabrication

- Powder Metal

- Roto & Blow Molding

- Sheet Metal - Hydroforming

- Sheet Metal - Roll Forming

- Sheet Metal - Stretch Forming

- Sheet Metal - Transfer Die

- Sheet Plastic

Information displayed in the Validation tab varies somewhat by process group but generally includes the following panels:

- Uncosted GCDs - to alert the user that the cost estimate is not complete

- Tolerances - so user can ensure key tolerances were entered and/or read from the CAD model

- Routing - so user can ensure the selected manufacturing routing matches the one that is intended

- Draw Direction or Ram Direction (for Plastic Molding, Castings, or Stampings) - so user can verify the tool open/close direction, since this can significantly affect tool design and cost estimates

- Stock Form - for Bar & Tube Fabrication, Forgings, and Machined parts - since assumed stock affects both material cost and the need for material removal operations

- Blank Size - for Sheet Metal parts, so users can verify the dimensions shape of the flat-pattern calculated by aPriori, since this significantly impacts estimated material cost

- Machining - to alert the user if machining operations are considered necessary to make features on the part

The specific panels of information displayed in the Validation tab now can be configured by Digital Factory Administrators. A new lookup table validationDisplayControls is used to control which panels and metrics are displayed, as shown below. The value in the display column controls whether the panel is visible in the Validation tab.

| panelName | Display |

|---|---|

|

Blank Size |

yes or no |

|

Build Direction |

yes or no |

|

Draw Direction |

yes or no |

|

Machining |

yes or no |

|

Main Surface |

yes or no |

|

No Cost Feature |

yes or no |

|

Ram Direction |

yes or no |

|

Routing |

yes or no |

|

Stock Form |

yes or no |

|

Tolerances |

yes or no |

|

Uncosted GCDs |

yes or no |

Note: Validation tab configuration options are available for all process groups except for 2-Model Machining, Composites, and Multi-Spindle Machining process groups.

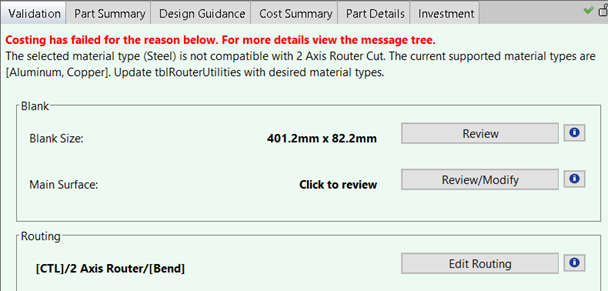

The Validation tab now provides more specific information when a part fails to cost in aPriori, enabling the user to understand the reasons for failure without having to look elsewhere in the application. An example of this more specific messaging is shown below.

Figure: Validation tab

The Validation tabs are displayed automatically for customers who are using or upgrade to the most recent cost model versions. Older cost models also can be configured to display the Validation tabs, without otherwise upgrading to the latest cost model version.

To display the Validation tab for each process group of interest:

- Add the cost model variable genericValidation = true

- Add the lookup table validationDisplayControls

For more assistance, please consult your aPriori account representative.

Improved Naming and Organization of Design for Manufacturability and Cost Issues

aPriori has improved how it categorizes and describes design feedback to better help engineers identify and understand both manufacturability issues and cost-driving issues.

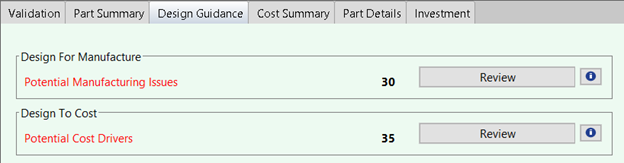

In aPriori 2022 R1, the Design to Cost tab is renamed to Design Guidance to better convey that it provides feedback about both manufacturability issues and cost-driving issues.

The Design Guidance tab now provides two separate panels Design For Manufacture and Design To Cost to help users more easily identify features that cannot be manufactured reliably versus those that just may incur extra cost.

Figure: Design guidance

In previous releases all design issues were summarized via a single panel which had a name specific to the process group (e.g. Plastic Issues, Casting Issues, or Machining Issues). All issues that previously were identified by aPriori continue to be displayed in aPriori 2022 R1, but some now will be displayed via the Design For Manufacture panel and some via the Design To Cost panel:

- The Design For Manufacture panel identifies part geometry that either cannot be manufactured with the primary process or violate “best practice” manufacturing recommendations.

- The Design To Cost panel provides feedback on geometry that may be increasing the cost of the scenario by requiring extra manufacturing steps or processing that is slower or more complex.

Note: For customers who have upgraded to aPriori 2022 R1 but not upgraded to the latest cost model version, all issues will be displayed in the Design For Manufacture panel. You can configure the relevant issues to appear in the Design To Cost panel by adding the attribute custom.panelOutput with the value costDrivingIssue to the dtcMessage( ) for each issue of interest.

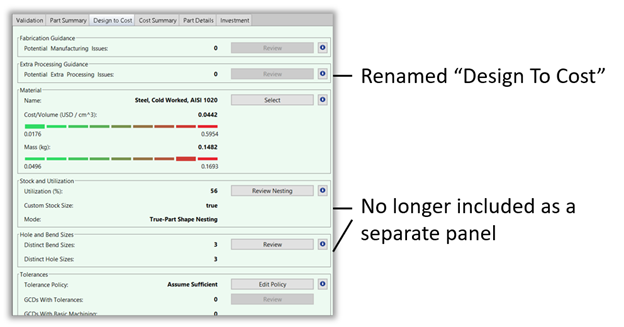

Note: In previous releases, the Design to Cost tab in the Sheet Metal process group included a panel named Extra Processing Guidance. This panel is not included in the Design Guidance tab in aPriori 2022 R1. All issue types previously reported in the Extra Processing Guidance panel are included in the Design To Cost pane in aPriori 2022 R1.

Improved Usability of Design Guidance Issues Dialogs

aPriori 2022 R1 improves the clarify and usefulness of the Issues dialogs which are invoked from the Design Guidance tab.

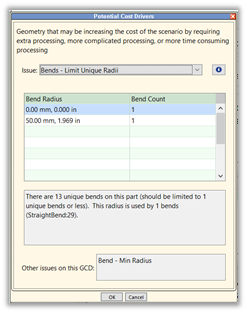

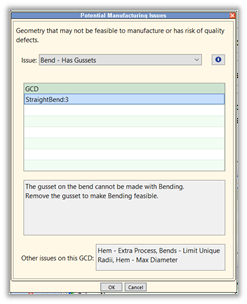

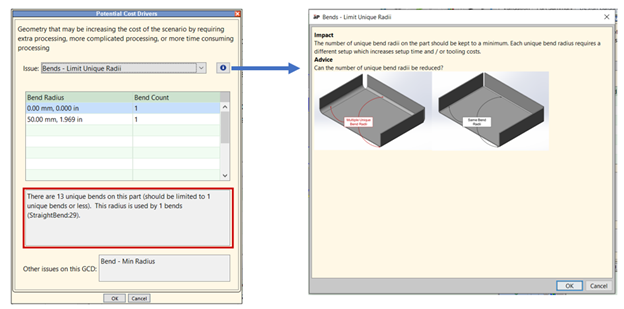

Clicking the Review button in the Design for Manufacture or Design To Cost panel invokes a dialog called Potential Manufacturing Issues or Potential Cost Drivers, respectively. These dialogs display the various types of issues found on the part and specific issues of each type. Several updates were made to these Issues dialogs to make it easier for the user to understand and respond to the feedback provided.

-

Different tabular displays now are used for different types of issues, to best convey the most relevant data fields to understand the issue. An example is shown below:

Figure: 2-column display for Unique Bend Radii issue

Figure: 1-column display for Bends with Gussets issue

- As pictured above, If a GCD has more than one issue, users can inspect the details each individual issue but also see a list of the other issues at the bottom of the Issues dialog. This enables users to more quickly and comprehensively understand how the GCD should be re-designed.

- When an issue involving or affecting multiple GCDs is selected, now all of the affected GCDs are highlighted in the Viewer, to help the user understand the scope of the issue.

Note: These updates to the Issues dialogs will be visible only if you have upgraded to the latest cost model version and cost the part in that version. Otherwise, the dialogs will appear as they did in previous releases.

Improved Explanations of Design Issues

The explanatory information provided for design issues now follows a consistent format, enabling users to more easily understand the specific problem, the impact of the problem, and the potential approaches they can take to resolve the problem.

As in previous releases, aPriori 2022 R1 displays explanations of each issue found on the part. There is a text explanation displayed in the Issues dialog itself, and a secondary Help dialog that includes a visual illustration of the issue.

Figure: Secondary message

The secondary Help dialog now provides two standard pieces of information in a consistent format:

- Impact - a brief description of the impact this problem may cause, for example, scrapped parts, a slower process, or additional tooling and expense.

- Advice – a prompt for the user to think about how the problem can be solved, typically in the form of a question.

Customers who upgrade to aPriori 2022 R1 will see these updated Help dialogs even if they do not upgrade their cost models to the latest versions.

Updates to Sheet Metal Design Guidance

In aPriori 2022 R1, the Design Guidance tab for the Sheet Metal process group was updated to make it more consistent with these tabs in other process groups and to make the design feedback more actionable. Some new types of Design To Cost feedback also now are provided.

In previous releases, the Sheet Metal Design to Cost tab included specialized panels Extra Processing Guidance, Stock and Utilization and Hole and Bend Sizes, as shown below. The Extra Processing Guidance panel now is renamed the Design To Cost panel. The Stock and Utilization and Hole and Bend Sizes panels no longer are included in the updated Design Guidance tab. See Sheet Metal Enhancements

Figure: Design to Cost tab

However, issues related to material utilization, stock sizes, hole sizes and bend sizes now will be presented in the Design To Cost panel. Specific guidance is provided for each type of issue, including:

- Low Material Utilization estimated material utilization is less than 75% (or configured threshold) - the user is alerted if the estimated material utilization is less than the value specified by the metric minUtilization in the lookup table tblDTCBlankGuidance; this is set to 75% in the baseline cost models.

- Custom Stock Thickness - the user is alerted if the part thickness does not match an available standard stock thickness, as defined in the Digital Factory, but is otherwise small enough on a standard sheet size.

- Limit Unique Bend Radii - the user is alerted if the part contains multiple bends of varying radii, rather than a single consistent bend radius value. The number of distinct bend radius values that is acceptable can be configured via the metric uniqueBendRadiiMax in the lookup table tblDTCBendGuidance; it is set to 1 in the baseline cost models.

- Limit Unique Hole Sizes - the user is alerted if the part contains multiple holes of varying diameter, rather than a single consistent diameter value. The number of distinct diameter values that is acceptable can be configured via the metric uniqueHoleSizesMax in the lookup table tblDTCHoleGuidance; it is set to 1 in the baseline cost models. This limit can be made routing-specific if desired, by adding a row per process in the lookup table, with the process name specified in the and updating the value in the Operation column to the respective process name.