Sustainability Insights Enhancements

- Sustainability Insights for Assembly Processes

- Carbon Estimates for Machining Auxiliary Energy

- Updates to Machine Rated and Spindle Powers

- Energy Consumption available in the Geometry Analysis Tool

Sustainability Insights for Assembly Processes

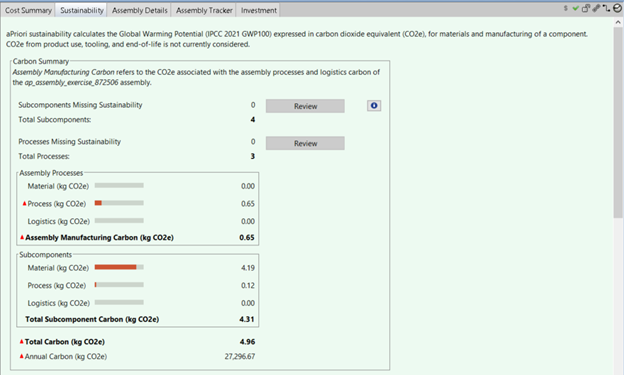

aPriori 2024 R1 SP1 now provides carbon emissions estimates for all processes in the Assembly process group. The Assembly process group now provides a Sustainability tab, which displays the carbon estimates for both assembly processes and subcomponents included in the assembly.

aPriori 2024 R1 SP1 introduces carbon estimates for all processes in the Assembly process group. The following processes are included:

| Adhesive Bonding | Mechanical Assembly |

| Cap Sealing | Pick and Place |

| Electron Beam Welding | Rivet |

| Fay Sealing | Robotic MIG Welding |

| Fillet Sealing | Robotic Spot Welding |

| Laser Welding | Robotic TIG Welding |

| Lock Bolt | Threaded Insert |

| Manual MIG Welding | Ultrasonic Welding |

| Manual Spot Welding | Weld Clean Up |

| Manual TIG Welding | Weld Prep |

aPriori 2024 R1 SP1 introduces a new Sustainability tab for the Assembly process group. This tab provides an overview of the sustainability coverage of assembly, alongside a breakdown of carbon by assembly components and Assembly processes applied to the assembly.

The Carbon Summary section shows the subcomponent and Assembly process coverage and a breakdown of the assembly's total carbon footprint. When the assembly contains subcomponents or processes that are missing sustainability results, users can get additional information by clicking the Review button.

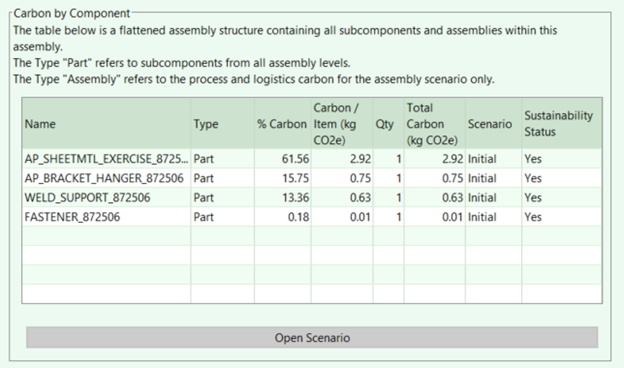

The Carbon by Component section allows users to explore a detailed breakdown of subcomponent carbon footprints within the assembly. This flattened view displays all nested subcomponents and assemblies, with default sorting by "% Carbon" to pinpoint the biggest contributors. Users can then select a component and click Open Scenario for further details.

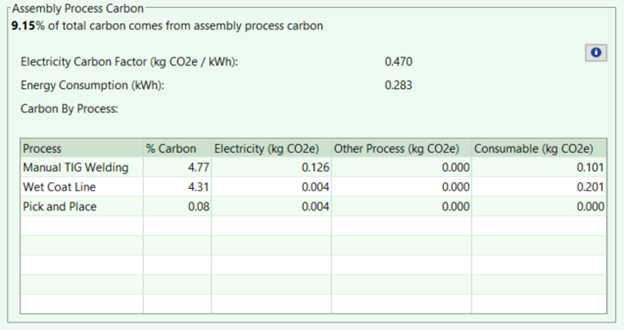

The Assembly Process Carbon section breaks down the carbon footprint contributions of each process applied to the current assembly. Together with the Carbon by Component section, this provides a comprehensive view of the embodied carbon footprint for the entire assembly, including all subcomponents.

Additionally, carbon data can be examined for the assembly processes and subcomponents in the updated Assembly Summary spreadsheet report. This includes:

-

The total carbon associated with each assembly process or subcomponent

-

The contribution percentage of each assembly process or subcomponent to the overall assembly’s embodied carbon footprint

-

The Sustainability status for each entry, indicating the sustainability coverage of the assembly and subcomponents.

For more information, see Assembly Summary Report in the aP Pro User Guide. This report also is available from aP Design.

Carbon Estimates for Machining Auxiliary Energy

aPriori 2024 R1 SP1 expands energy consumption calculations to incorporate auxiliary power requirements for the machines.

In aPriori 2024 R1 SP1, machining process carbon estimates now include auxiliary energy consumption. This is energy consumed to support the machine's non-cutting components (for example, coolant pumps, chip conveyors, and so forth). Previously, aPriori provided estimates only for carbon emissions due to the energy required for the machine’s spindle to remove material from the workpiece.

To account for auxiliary energy, an additional machine property called Auxiliary Power has been introduced. This considers the power requirements of the auxiliary components, providing a more comprehensive understanding of the process's carbon footprint. Auxiliary Power is applied across the entire machining cycle, including previously unaccounted times like part setup time. This allows for a more accurate estimation of the total energy consumption.

As part of this implementation, the rated and spindle (cutting) machine property fields were reviewed for every machine in the Machining process group, see Updates to Machine Rated and Spindle Powers for more information.

An impact analysis was conducted on 156 parts across a range of primary process groups. This analysis showed a direct relationship between machining cycle time and energy consumption. The greater the machining cycle time, the greater the increase in energy consumption. This is expected behavior as auxiliary power is required throughout the machining cycle. Parts with large cycle times for secondary machining also saw significant increases in overall energy consumption.

Due to this enhancement, energy consumption estimates will increase significantly compared to the previous release of the Machining process model. An impact analysis was conducted on 156 parts across a range of primary process groups. This analysis showed a direct relationship between machining cycle time and energy consumption. Given this relationship and the variance in auxiliary power across machine types and sizes a large range of energy consumption increases were observed. The average increase in energy consumption was 39 kWh. The largest increase in energy consumption being seen on a part with 94,605 seconds (26.2 hours) of machining cycle time, this increase was nearly 890 kWh.

Note: A check was introduced into the Machining process group to ensure the sum of the main cutting tool power and the auxiliary power does not exceed the total rated power of the machine. This check will apply to all customers (including those without a sustainability license) once the manufacturing process model is upgraded to this latest version (CMV 310). As a result, an Auxiliary Power value will need to be populated for all custom machines in the Machining process group. If this is not known, the value from a similar baseline machine type and size could be leveraged. This value can be set to zero if the auxiliary power requirements for a given machine are negligible, such as for older machines with little-to-no auxiliary equipment.

Updates to Machine Rated and Spindle Powers

aPriori 2024 R1 SP1 has reviewed and updated all machine rated and spindle (or cutting) powers in the Digital Factory.

In aPriori 2024 R1 SP1, significant updates were made to machine power values, as part of the implementation of Carbon Estimates for Machining Auxiliary Energy. Following a review of all machining processes, many updates were made to the values of machine spindle (or cutting power) and/or machine rated power to ensure agreement with published machine specifications and to provide consistency across machines in a given process.

When machine power rates were updated, machine direct overhead rates were directly affected as annual energy usage is an input to the Direct Overhead calculation. Additionally, in some cases, customers also may see some minor changes in machine selection and cycle time calculations. By default, aPriori selects a feasible machine with the lowest total overhead rate; relative changes in powers between two feasible machines may change this selection. aPriori calculates machining cycle time based on available spindle power to determine feed and speed rates. Modifications to the machine's spindle power or cutting power may affect these calculations, potentially altering cycle times. This may affect other cost calculations such as indirect overhead costs.

An impact analysis on 104 parts using aPriori baseline machines revealed an average increase of 13.6% in direct overhead costs and a minimal change (0.2%) in indirect overhead costs for parts analyzed in the Stock Machining or 2-Model Machining process groups. In a separate analysis, 113 parts cost against various process groups showed an average increase of 11.7% in direct overhead costs and a minor increase (0.4%) in indirect overhead costs, when secondary machining was involved.

Note: These updates to machine power values and therefore overhead values are available only to customers using the 2024-06 RDLs in conjunction with aPriori 2024 R1 SP1. For customers using the aPriori 2023 R1 releases, the previous machine power values are still in effect and overhead rates are not affected by the power updates describe above.

Note: Customers who have previously created custom machines utilizing a baseline machine's power values may want to review and update the custom machine values similarly. This could be performed while also adding the Auxiliary Power values described in Carbon Estimates for Machining Auxiliary Energy.

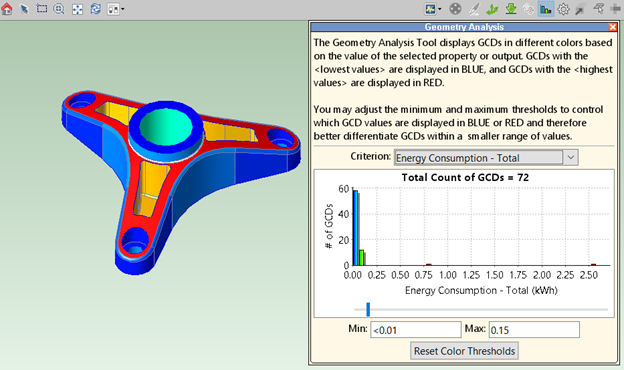

Energy Consumption available in the Geometry Analysis Tool

aPriori 2024 R1 SP1 introduces three energy consumption variables into the Geometry Analysis tool (also known as the Heat Map).

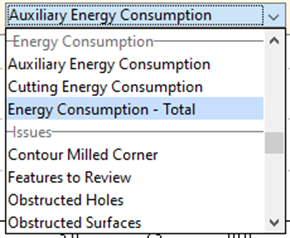

In aPriori 2024 R1 SP1, machining energy consumption has been added to the Geometry Analysis tool. After costing a part with the machining as a primary or secondary process, you can now visualize the energy consumed during the machining of each GCD. Three views are available:

-

Auxiliary Energy Consumption– This is energy consumed to support the machine's non-cutting components (for example, coolant pumps, chip conveyors, and so forth).

-

Cutting Energy Consumption – This is the energy consumed for the spindle to remove material.

-

Energy Consumption – Total – This is the total energy required to manufacture the part. This is the sum of Auxiliary Energy Consumption and Cutting Energy Consumption.

You can select a view by clicking a menu item in the new Energy Consumption section of the Criterion menu.