Casting - Investment Enhancements

Cycle Time Refinements and Improved Configurability

aPriori 2024 R1 SP2 updates how cycle time is calculated for many processes in the Investment Casting routing, making it more sensitive to part size and significantly lowering estimates of cycle time and Fully Burdened Cost, especially for small parts.

In 2024 R1 SP2, the Investment Casting process group was enhanced to produce more accurate cycle time and cost estimates across a range of part sizes. In previous releases, customers reported aPriori estimates were inflated, particularly for small parts. To achieve more mechanistic and accurate estimates, the manufacturing process model now includes three new lookup tables that give more granularity to cycle time drivers based on part weight, number of dip cycles, and core weight. The Ceramic Core Firing process logic also was updated to better estimate the number of cores that will fit in the Firing Oven.

The cycle time calculation for the Fluorescent Penetrant Testing process, which automatically is included in the Investment Casting routing, also was updated, leading to general reductions in cycle time for this process. See Fluorescent Penetrant Testing.

Additionally, a small issue in wax pattern molding was resolved, where previously the loading of soluble cores was not correctly accounted for by the logic.

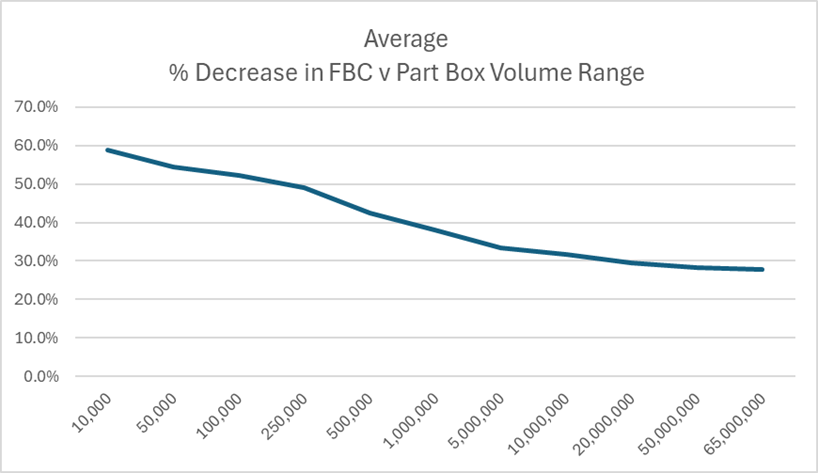

The result of the changes is a significant reduction in estimates of cycle time and therefore fully-burdened cost, with an average cost reduction of 27% across a large set of test parts of varying sizes, and a maximum cost reduction of 72% for the smallest part in our test suite. The following graph shows how fully-burdened cost decreased on average with part bounding box volume (in millimeters):

Lastly, aPriori introduced the ability to enable or disable the cost of Drying and Cooling in the Investment Casting model, as some customers and suppliers do not account for this process due to the fact the parts are not being handled and are sitting on the factory floor. By default, the processes are enabled. They can be disabled by changing the cost model variable includeDryingAndCooling or by changing the process option Include Drying and Cooling Processes to control the behavior on a scenario by scenario basis. Disabling these costs results in an average decrease in fully burdened cost of 41%.

Below are the details of the process updates.

The newly added lookup tables, containing size-based standard times per operation, are shown below:

-

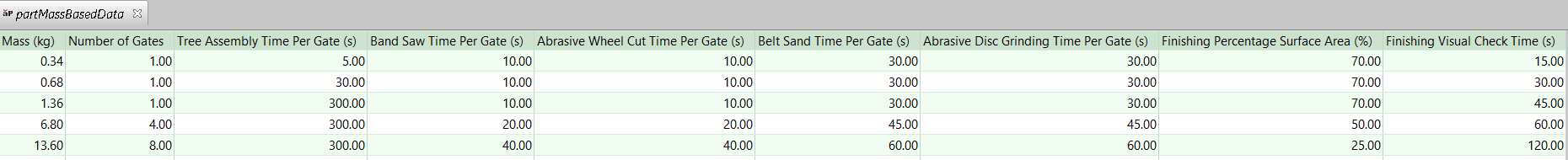

partMassBasedData:

Cycle time calculations for Bench Operations and the calculation of the number of gates per part now consider the cast mass of the part for greater cycle time accuracy, and standard times per operation are generally reduced across the range of part sizes. Previously:

-

Tree assembly time per gate was 300 seconds for all parts.

-

The gate cut times were set as 120, 300, and 600 seconds based on small, medium, and large parts.

-

The grind times were set as 300, 900, and 1800 seconds based on small, medium, and large parts.

-

Percentage of surface area a finishing operation was applied to was 100%.

-

The visual inspection time was 30 seconds for all part sizes.

-

-

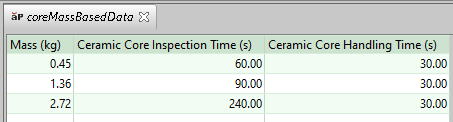

coreMassBasedData

-

The dimensional inspection time for ceramic cores now considers the mass of the core. Previously it was specified by a cost model variable with a default of 300 seconds for all parts.

-

The labor time for handling ceramic cores in the firing process has been increased from 1 second to 30 seconds.

-

-

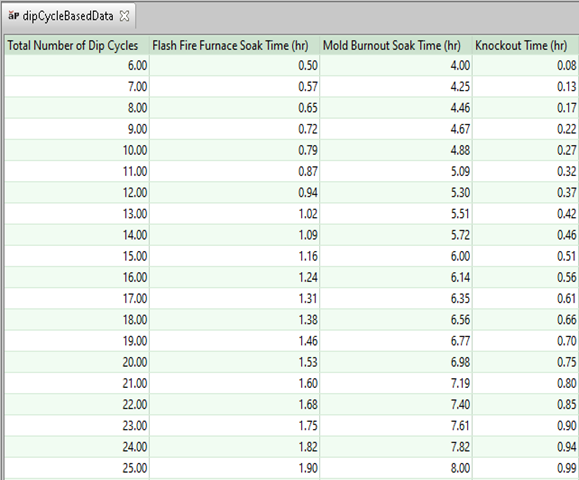

dipCycleBasedData

The cycle time calculation for Knockout now considers the number of dip cycles, and the soak times for Flash Fire Furnace and Mold Burnout were reviewed and reduced. Previously:

-

Knockout time was specified by a cost model variable as 0.33hours.

-

Flash Fire Furnace soak times ranged between 3 and 7.1 hours.

-

Mold Burnout Soak Times ranged between 5 and 9.1 hours.

-

The update to Ceramic Core Firing is as follows :

-

Previously aPriori assumed a single layer of cores in the oven and assumed the number of cores was related to the core area compared to the oven floor area.

-

Previously aPriori had a hard coded lower limit that assumed a core would utilize at least 1% of the oven floor space. This assumption was very conservative for small parts with small cores.

-

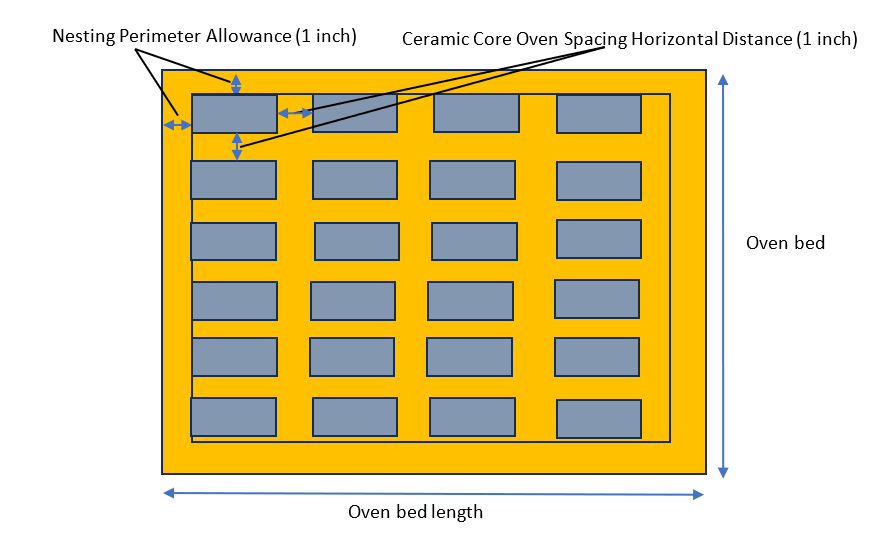

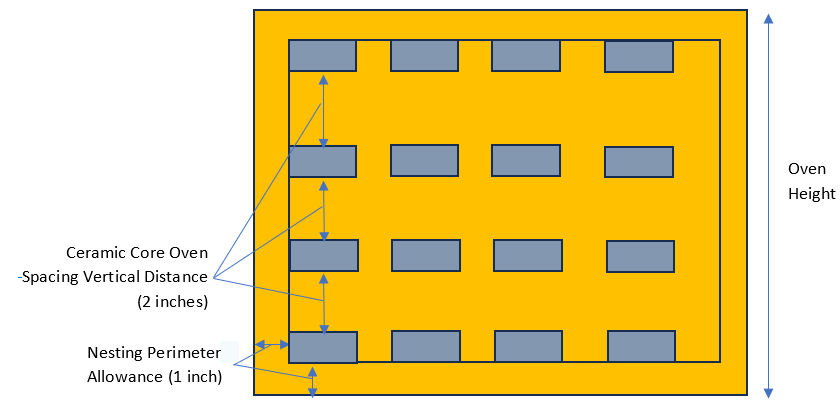

Now aPriori calculates the number of cores that will fit in the oven with a basic 3-dimensional nesting algorithm:

-

The cost model variable nestingAllowance_perimeter_ceramicCoreFireOven (25.4mm by default) controls how close a core can be placed to the edge of the oven.

-

The cost model variables ceramicCoreOvenHorizontalSpacing (25.4mm by default) and ceramicCoreOvenVerticalSpacing (50.8mm by default) control the spacing of the cores in the horizontal and vertical directions.

-

The spacing plus the core dimensions are used to calculate how many cores can fit in the oven.

-

Example of the new logic is as follows:

-

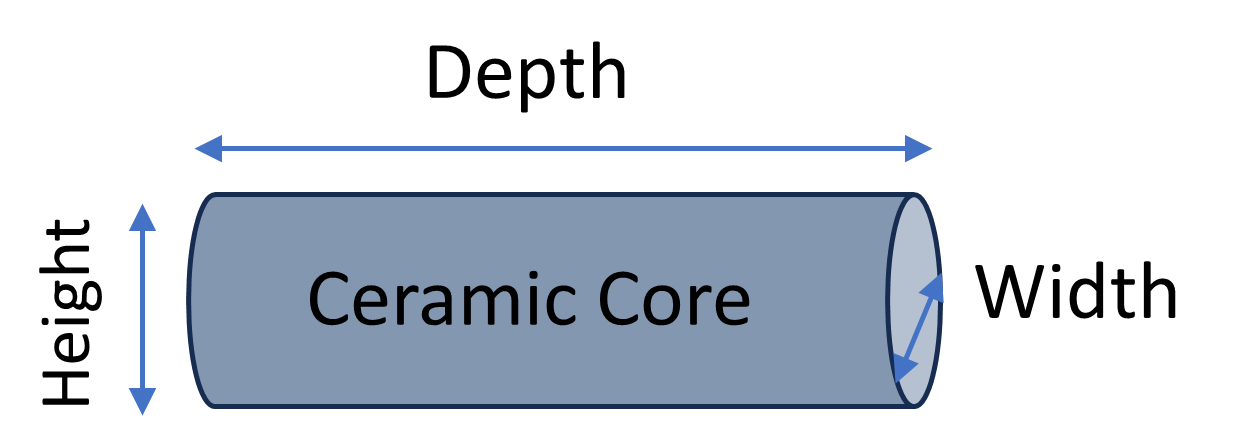

Core Dimensions are understood by the cost model.

-

aPriori calculates the number of cores that will fit in a single layer. Looking Top down on the oven in this case we can see 24 cores fit in a layer.

-

aPriori then calculates the number of layers that will fit vertically in the oven. Looking side on we can see that the oven fits 4 layers vertically, resulting in 96 cores fitting in the oven in total.