Machining Enhancements

aPriori 2024 R1 SP2 provides the following enhancements to the Machining process group:

- More Accurate Estimates of Part Setup Time and Cost for Machined Parts

- Improved Milling Tool Access and Setup Pairing

- Adjustable Default Pressure Angle

See also Stock Machining Enhancements and 2-Model Machining Enhancements.

More Accurate Estimates of Part Setup Time and Cost for Machined Parts

aPriori 2024 R1 SP2 provides more accurate and credible estimates of the part setup time required to machine a part, by considering both the size and weight of the part and more completely accounting for the various setup activities performed when machining a part.

Previously, machining part setup time accounted only for the time taken to load the part into position in the machine, using either a weightBased calculation based on the unmachined mass of the part (default), or a machineBased calculation, using a fixed machine variable.

In 2024 R1 SP2, aPriori now provides an updated default calculation method, weightAndSizeBased, which considers both the weight and the size of the part when determining the times required to perform various setup activities. It also now accounts for some part setup activities that previously were neglected. The Machining process model now includes a new lookup table componentLoadTime which is a copy of the same-named table in the Assembly process group.

This table contains times required to load, reorient, and unload parts of a certain size and weight, depending on the type of equipment being used. For simplicity, equipment is categorized into classes: No Equipment, Level 1 (representing unpowered lifting equipment like hoists), Level 2 (representing small, powered devices like hoists and winches), and Level 3 (representing large, powered devices such as gantries and cranes). Another column accounts for the number of operators required for components of a given size and weight range; larger and heavier components require multiple operators. Previously, part setup activities were assumed to be carried out by one operator (using a forklift over 20Kg) up to 500kg. Parts exceeding 500kg were assumed to require two operators using a crane. This lookup table can be configured easily by Digital Factory administrators if desired.

The part setup time calculation now includes times for the following activities. Activities with an asterisk (*) previously were not included in the setup time calculation :

-

Part loading time

-

Part unloading time*

-

Part reorientation time*

-

Door open time*

-

Door close time*

-

Clamping time*

-

Unclamping time*

-

Blow down time*

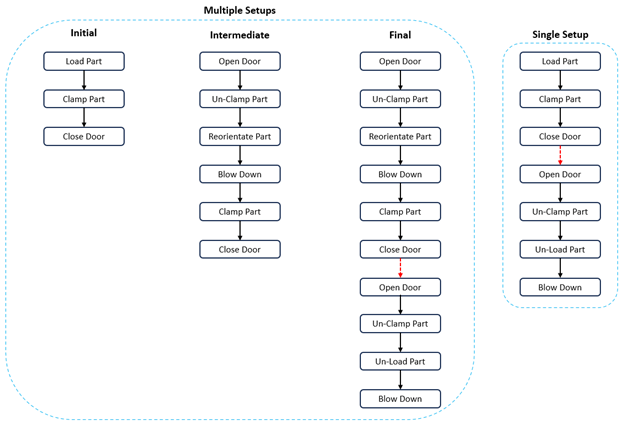

A setup time is calculated for each setup axis required to machine the part features. Each setup calculation mechanistically accounts for the position within the part's manufacturing processing. This is summarized by the workflow below:

Improvements in machining part setup time apply to both parts that are Stock Machined and parts that require secondary machining.

Note that the default setup time values provided in the componentLoadTime table assume the use of fixtures that quickly locate the part (such as “dovetails”), and do not reflect a slower, more labor-intensive approach of manually locating and measuring the part after each setup/reorientation.

Due to this enhancement, estimates of part setup time change, compared to the previous release of the machining manufacturing process model. On average, part setup time increases because aPriori accounts for more setup activities. However, part setup time decreases for some parts, as the size and weight of the part and the equipment used now are considered.

The table below shows how total cycle time estimates change for a set of machined test parts (analyzed in Stock Machining, 2-Model Machining, and process groups with secondary machining). The impact of these enhancements to part setup time is greatest for small parts with low overall cycle times, as part setup time represents a large fraction of total machining time. For larger or more complex parts with longer machining cycle times, the additional part setup time represents a diminishing fraction of the total cycle time and cost.

Each row of the table represents a set of parts for which the total cycle times (as estimated in the previous release) fell within a specified range, and it displays how much cycle times change in seconds and as a percentage of the original cycle time estimate.

|

Previous Total Cycle Time Range per Part (s) |

Average Difference (s) |

Average Difference (%) |

|---|---|---|

| 0-100 | 54 | 128% |

| 101-500 | 58 | 26% |

| 501 - 1000 | 93 | 13% |

| 1001 - 5000 | 68 | 3% |

| 5001 - 20000 | -13 | -0.1% |

| >20001 | -1084 | -2% |

Improved Milling Tool Access and Setup Pairing

In 2024 R1 SP2, improvements were made in machining setups and tool approaches for milling processes.

In 2024 R1 SP2, aPriori has improved its evaluation of available setup axis for Rough Milling operations on for the StockTrim GCD and for Countering operations on various GCDs. As a result, aPriori will more often select better tool approaches for these operations. Additionally, aPriori also may select more appropriate setups for finish milling operations.

Adjustable Default Pressure Angle

aPriori 2024 R1 SP2 provides the ability for a Digital Factory Administrator to set a default value for gear pressure angle via a new site variable.

For gear (AxiGroove) GCDs, aPriori by default assumes a gear pressure angle of 14.5 degrees, a standard value. However, in practice many gears use a pressure angle of 20 degrees, another standard value. Customers have requested the ability to modify the default value used for all AxiGroove GCDs.

In aPriori 2024 R1 SP2, Digital Factory administrators can now modify the default gear pressure angle for the aPriori deployment. This reduces the number of occasions on which a user must override the default gear pressure angle when the default is not suitable.

A new site variable, axigrooveGearPressureAngle, was created to allow Digital Factory administrators to set the deployment default for pressure angle. This site variable was added to each primary process group that extracts the AxiGroove GCD:

-

2 Model Machining

-

Additive Machining

-

Casting Die

-

Casting Investment

-

Casting Sand

-

Forging

-

Multi-Spindle Machining

-

Stock Machining

The pressure angle can still be updated on a per simulation basis by modifying the AxiGroove properties using the Gear Definition dialog—see Overriding AxiGroove Properties. in the Cost Model Guide.

Note that modifying the pressure angle has a very small impact on manufacturing estimates (for example, very slightly affecting hobbing tool travel distance and cycle time). Customers however wish to see a pressure angle that matches their actual gear specifications.

.