See how different manufacturing options affect carbon impact for a part

This example shows how to see the differences in carbon impact by comparing four different scenarios (differently manufactured versions) for the same part.

In aP Pro, you can compare an unlimited number of scenarios. The scenarios in a comparison can be for any type of component. That is, a scenario comparison can include multiple scenarios for the same part or assembly, different parts and assemblies, and both parts and assemblies.

Consider a car side panel that you are asked to make from sheet metal. There are many different ways that you could use to make the panel. To make the panel from a single piece of sheet metal, you could use different processes or you could use the same processes but in a different order. For example, you could cut, shape, and then machine it; machine, cut and then shape it; or machine and then stretch form it. You could also make the panel as an assembly of smaller sheet metal panels that are welded together. For each of the smaller panels, you could choose the same or different processes and orders. For each process, you must also decide on the materials and supplies that are used and the tools that are used to perform the process.

You might also have the option to make a single-piece panel, or the parts of an assembled panel in different factories that are in the same or different regions of a single country, continent, or other geographical region. If you do, you may have different options for the shipping and storage of the panel, or the parts of the panel assembly.

There are many options that you must choose between when deciding how, from what, and where to make your sheet metal panel. If you have the option to make the panel out of either sheet metal or another type of material, such as plastic, the number of options increases dramatically. With each choice that you make, the cost, manufacturability, and sustainability of the panel can change.

In aP Pro, you can make a different scenario for each set of options that you want to consider for making a component, as either a single part or as a multiple part assembly. By comparing the scenarios, you can examine differences in the cost, sustainability, and manufacturability of each set of processes, process orders, materials, tools, and factories that are used to make that component.

For more information about scenarios and scenario comparisons, see:

-

Creating and editing comparison summary views

Requirements

To enter and analyze sustainability data, you must have an aPriori Sustainability License and aP Pro 2023 R1 or later.

Limitations

-

aP Pro does not yet support Sustainability analysis for all process groups. For a list of currently supported process groups, see Processes supported in Sustainability.

-

Carbon from product use, tooling, and end-of-life is not currently considered.

Prerequisites

This example requires at least two different scenarios for the same part. Each scenario must:

-

Use a process group that is supported for Sustainability.

-

Be costed in a version of aP Pro that includes a Sustainability License.

Procedure

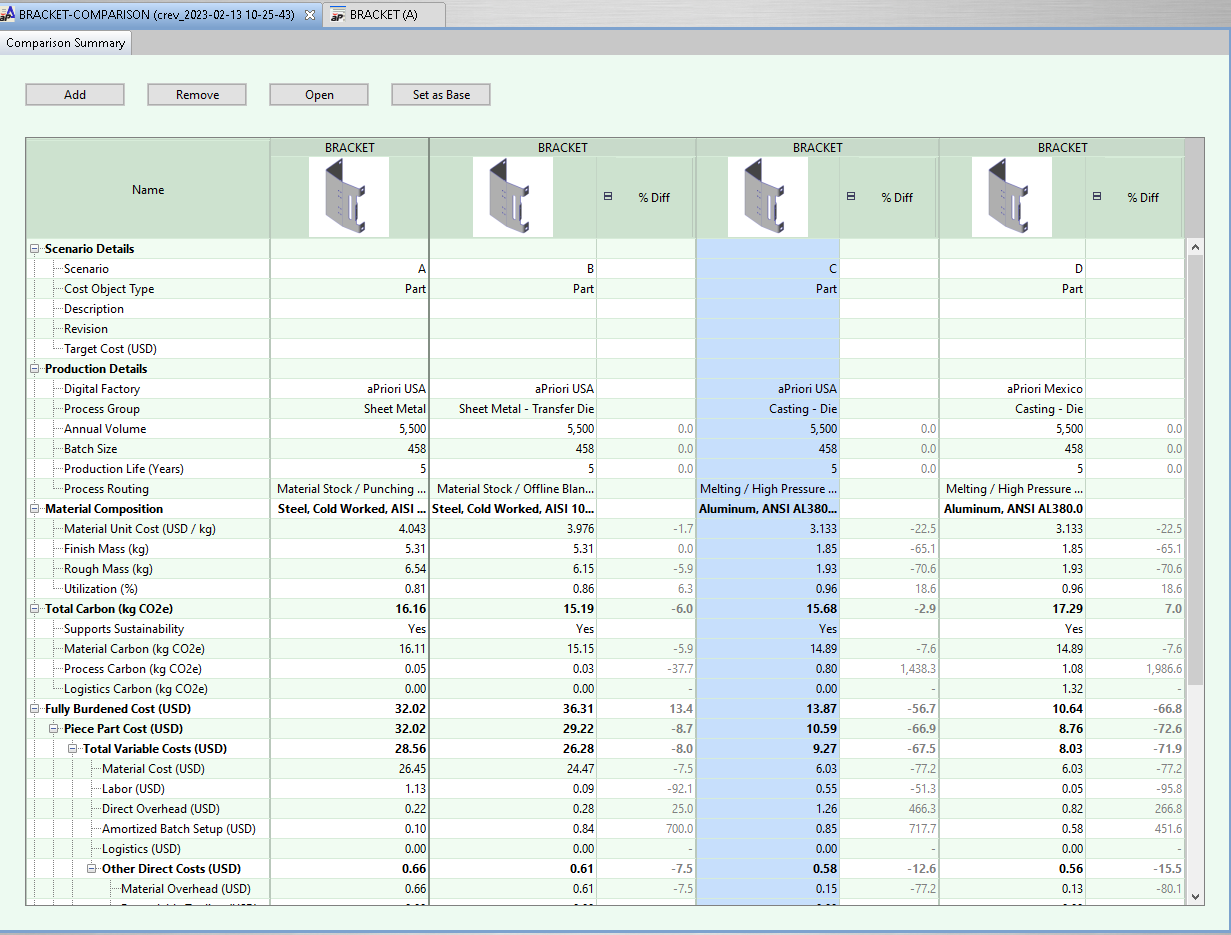

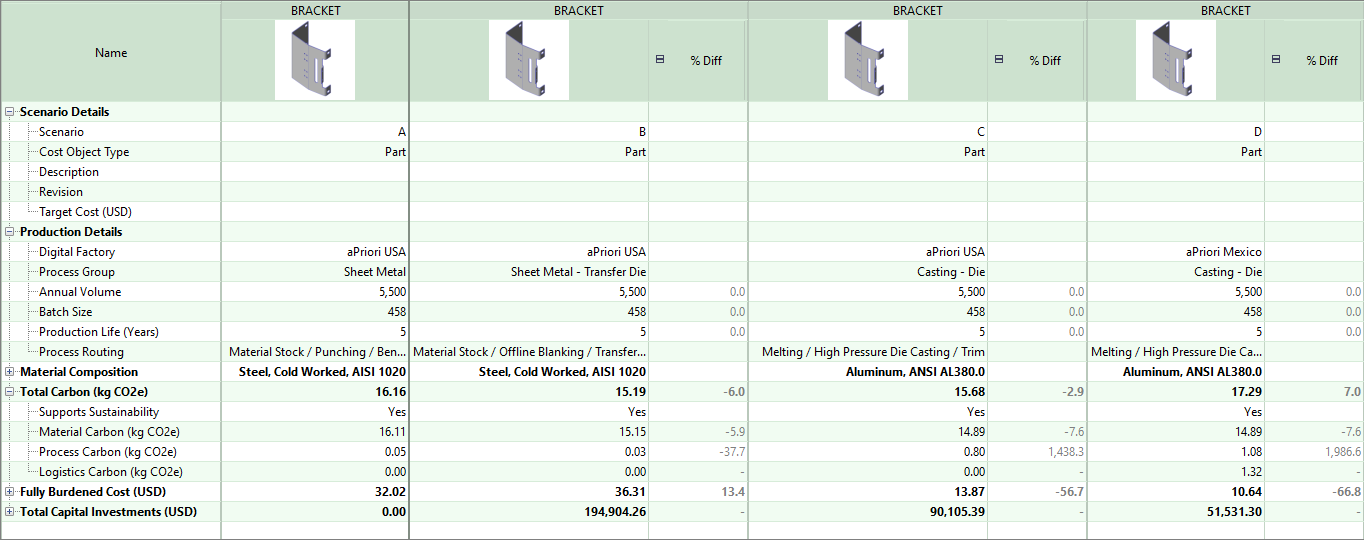

This example uses four scenarios for a simple bracket part. This table describes the major differences between the four scenarios.

|

Name/Part# |

Scenario | Process Group | Digital Factory | Custom Sustainability Settings |

|---|---|---|---|---|

|

BRACKET

|

A |

Sheet Metal |

aPriori USA |

– |

|

B |

Sheet Metal - Transfer Die |

aPriori USA |

– |

|

|

C |

Casting - Die |

aPriori USA |

– |

|

|

D |

Casting - Die |

aPriori Mexico |

Includes Logistics Carbon. For more information, see Edit the Logistics Carbon for a part. |

-

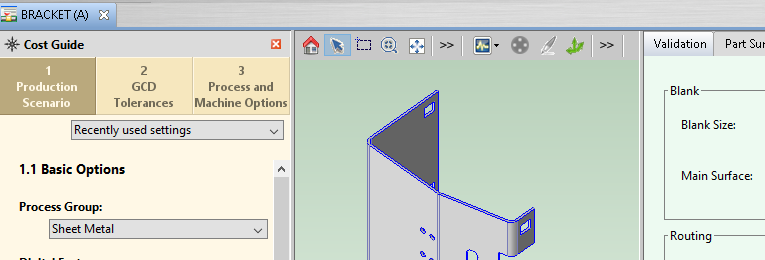

Open any one of the scenarios that you want to compare. For this example, the BRACKET (A) scenario is open.

-

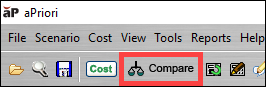

In the aP Pro menu bar, click Compare.

The Create Comparison dialog opens.

-

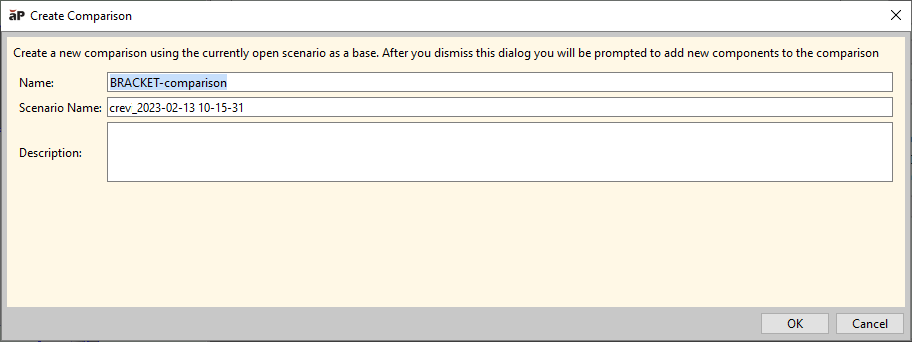

Optionally, in the Create Comparison dialog you can edit or include a:

-

Name – By default, this field contains the name of the component, followed by "-comparison".

-

Scenario Name – By default, this field contains your user name and the date and local time that you created the comparison.

-

Description – It is typically useful to enter a short description for the comparison.

-

-

To continue, click OK.

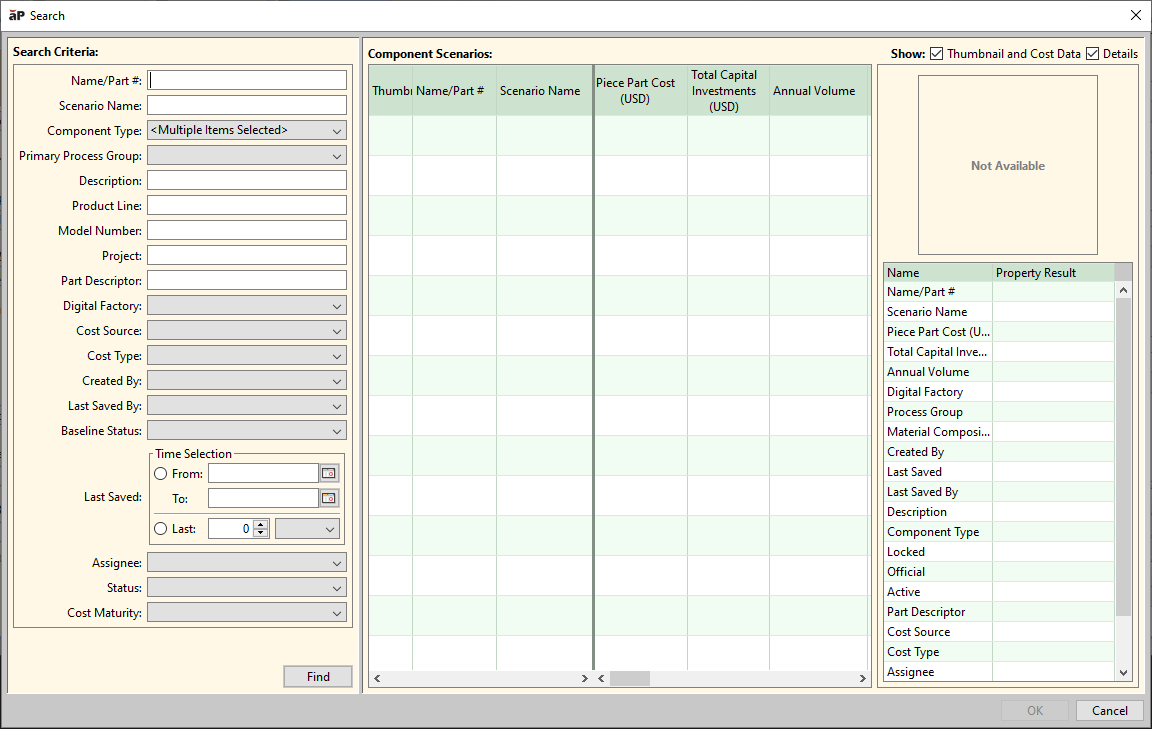

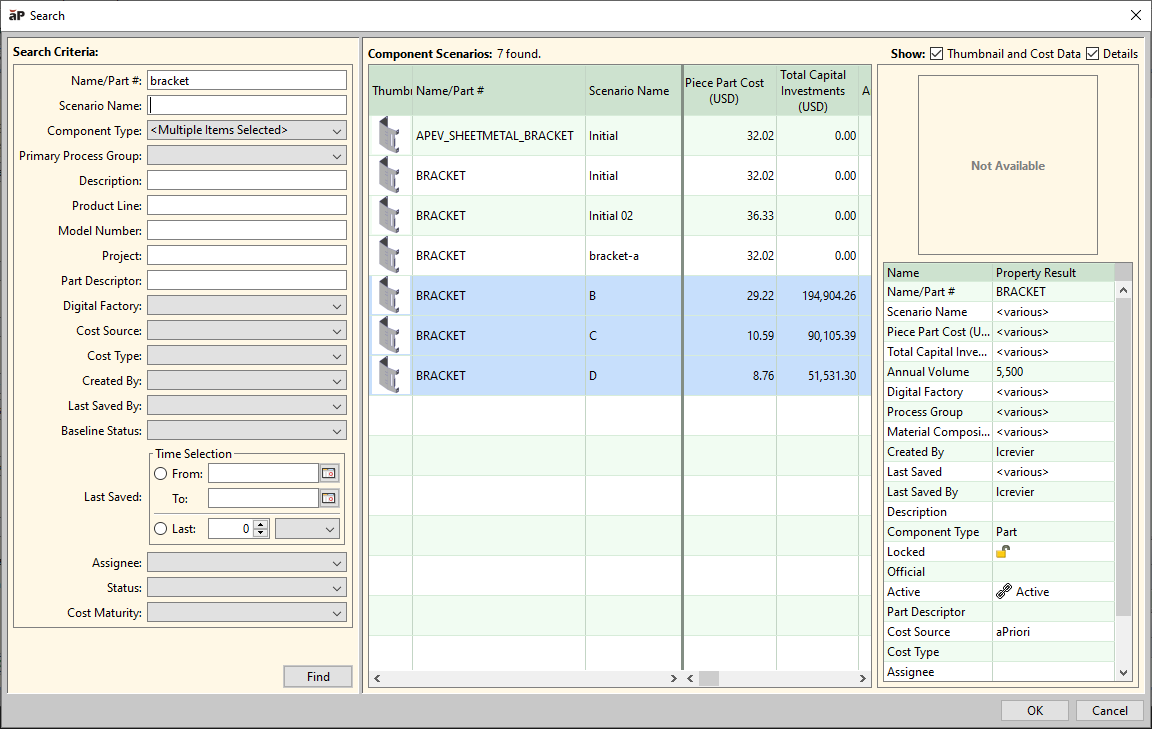

The Search dialog opens.

-

In the Search dialog, in the Search Criteria pane, enter any filter criteria that would yield one or more of the scenarios that you want to compare the open scenario to and then click Find.

For this example, because the Name for the component is the same in all of the scenarios of interest, BRACKET is entered in the Name/Part# field.

-

In the Component Scenario pane, select one or more scenarios that you want to add to the comparison and then click OK.

Tip: To select more than one scenario, use Ctrl+Click.

The Comparison Summary opens.

The scenario in the second column on the left is the base (or reference) scenario column. The data for all other scenarios is compared to the data for the base scenario column and the difference in values is displayed as a percentage in the % Diff column for each non-base scenario. To change the base scenario, drag and drop the column for that scenario to the base scenario column.

Tip: To add additional scenarios to the comparison, click the Add button.

Note: The unit that is displayed in the sustainability fields depend on the selected unit for Mass in your Unit System Settings.

-

To focus on a particular set of data, in the first column of the Comparison Summary, close the nodes for other types of output. For this example, to focus on the sustainability data, which is in the Total Carbon (kg CO2e) node, the nodes for Material Consumption, Fully Burdened Cost, and Total Capital Investment are closed.

The sustainability data is included in the Total Carbon (kg CO2e) node.

Total Carbon (kg CO2e) is the total carbon emission for a single part, which is the mathematical sum of material, process, and logistics carbons for the part.

Supports Sustainability indicates whether the process group that is selected for the scenario is supported for sustainability. The possible values are:

-

Yes: aPriori Sustainability has carbon data for the materials and processes used.

-

Partial: aPriori Sustainability has carbon data for some of the materials and processes used. This means that the routing includes a mix of supported and unsupported processes.

-

No: aPriori Sustainability has no carbon data for the materials and processes used.

Material Carbon (kg CO2e) is the mass of the CO2 equivalent that is attributed to the raw materials of the part, that is, the carbon associated with the primary material rough mass and secondary materials (for example, paint) consumed during the manufacturing of the part.

Process Carbon (kg CO2e) is the mass of the CO2 equivalent that is attributed to the processes used to manufacture a part. Process Carbon includes the electricity and other energy sources used to turn the rough mass into the finished component.

Logistics Carbon (kg CO2e) is the mass of the CO2 equivalent that is attributed to the processes used to transport the part, including any processes that are used during transportation-related storage.

Tip: Although aP Pro does not calculate Logistics Carbon, you can manually enter a value for it. For more information, see Edit the Logistics Carbon for a part.

Note: In this example, the percentage difference is not displayed for the Logistics Carbon. If the baseline scenario had a value greater than 0 (zero), the percentage difference would be shown.

-

For this example, all process groups are supported for Sustainability. Although scenario E has the lowest Fully Burdened Cost (USD), it has the highest Total Carbon (kg CO2e). Other scenarios have higher costs, but are more sustainable in terms of kg CO2e.