Design to Cost

A frequent cause of Engineering changes are manufacturability issues – components that cannot be manufactured with sufficient quality for a reasonable cost, or manufactured at all. These changes can disrupt the design cycles, costing you time and resources.

This tutorial shows a suggested workflow to identify and resolve potential manufacturability issues, while identifying features driving highest costs on a component, before a product is released.

Identify Components with Manufacturability Issues

-

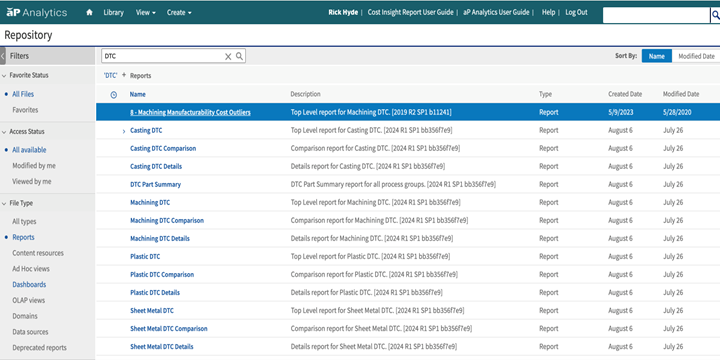

In aP Analytics, navigate to Reports and select the appropriate commodity based DTC report.

See the aP Analytics User Guide for more details of available reports.

-

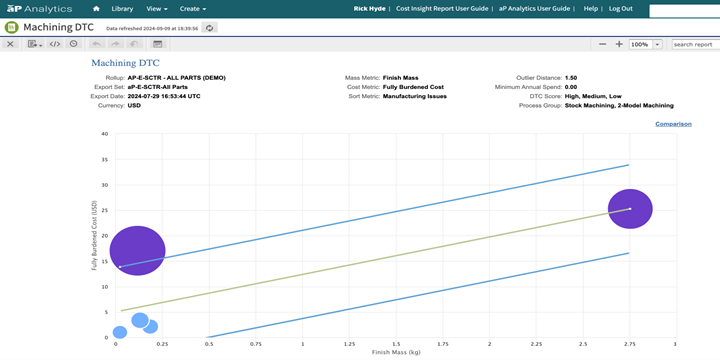

This report shows all of the components in the selected dataset, plotted on a cost/mass graph with high/low guard bands. The size of the bubble shows the annual spend, and the color represents DFM issues.

We suggest you target large, purple bubble outside the guard bands, as these represent high spend parts with significant manufacturing issues that have a cost/mass far outside the other parts in the cohort.

View aP Design DFM Guidance

-

Open the desired component in aPriori Design - see Open a Scenario.

-

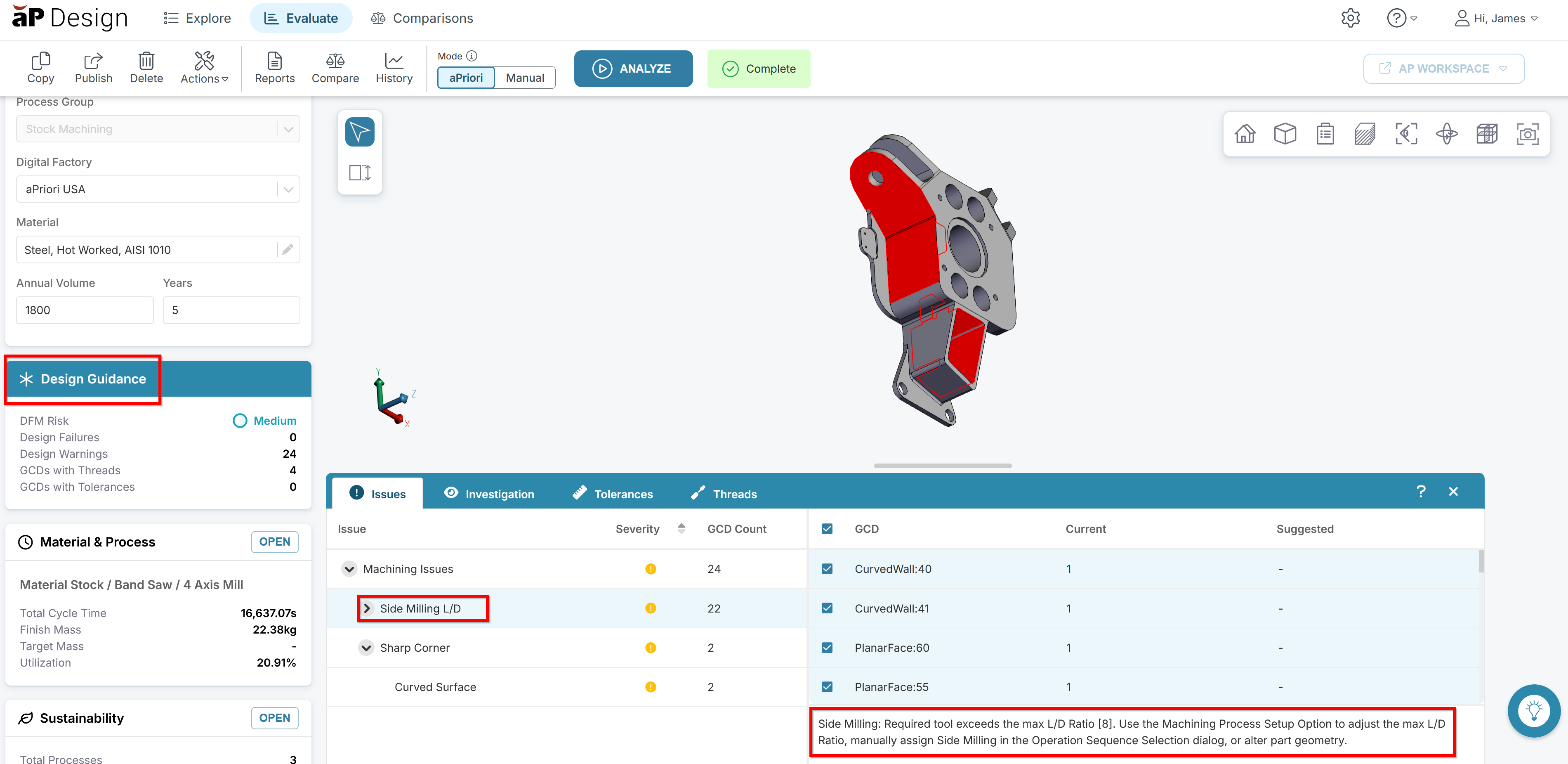

Navigate to the Design Guidance card and expand by clicking OPEN.

-

The Design Guidance highlights potential manufacturing issues on the component, describing the issue and techniques to mitigate.

-

We recommend going through each of the lines of guidance individually and evaluate whether the design recommendation can be reasonably implemented based on functional requirements.

See Review Design Guidance for more details.

Tip: Click on an issue to see a summary of the manufacturability issue.

Example

-

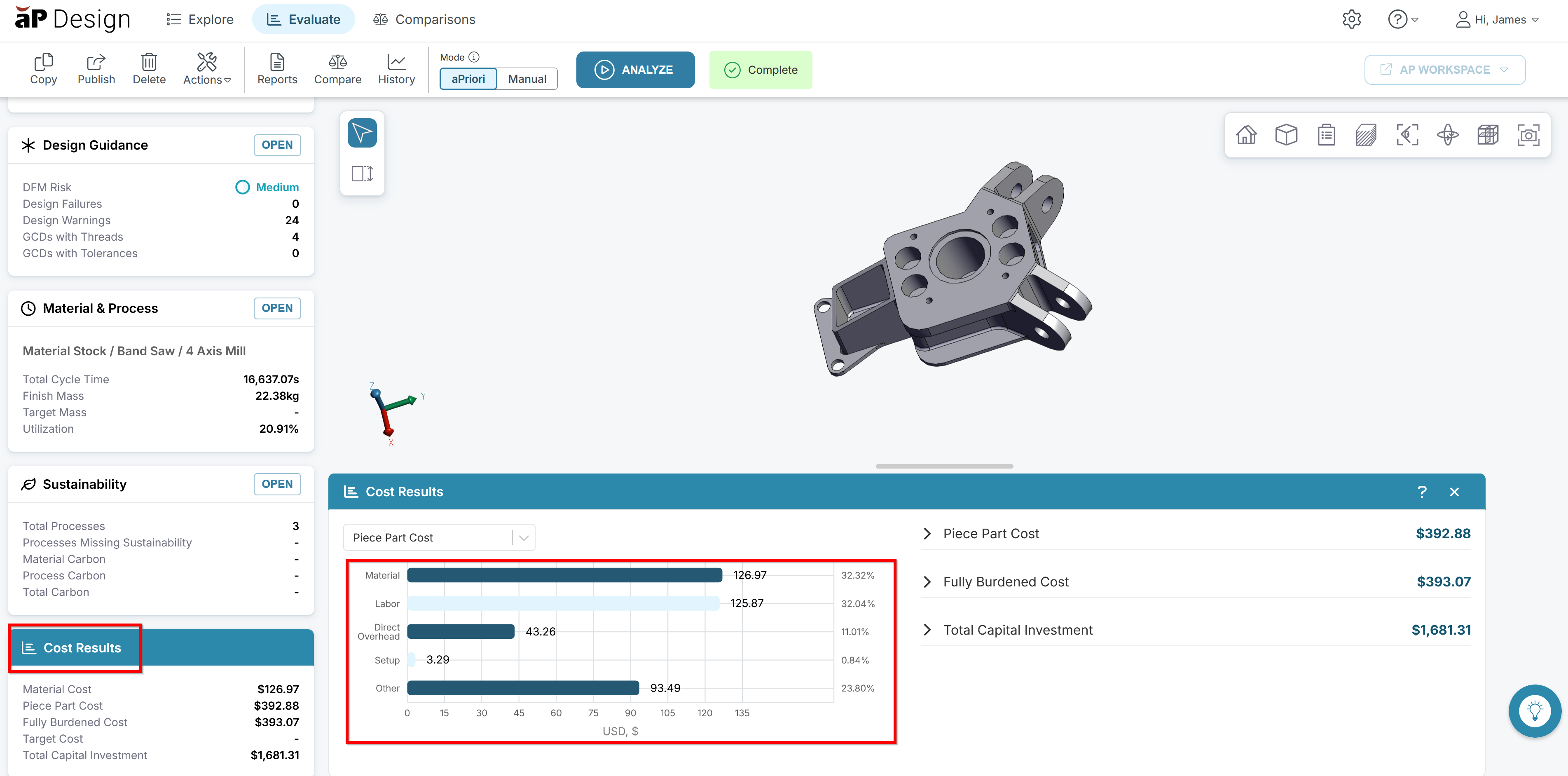

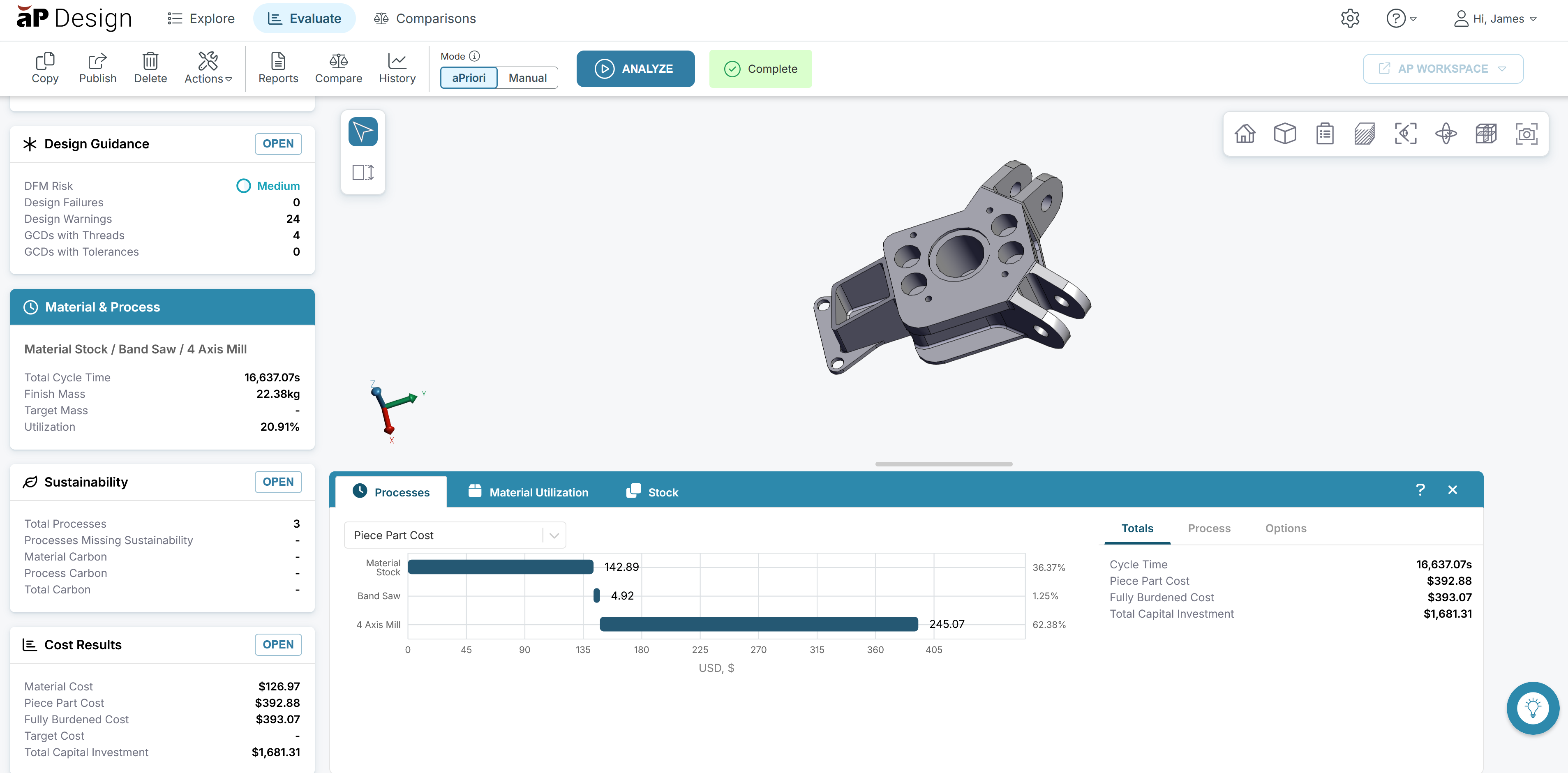

We start by analyzing a stock machined component. Click the OPEN icon to open the Cost Results card. You can use the information here to review which category most of the cost can be attributed to.

-

Looking at the Material & Processes card, we can see the breakdown of cost between the processes associated with the scenario. In this scenario 4-axis mill makes up most of the manufacturing, we’ll start our investigation there.

-

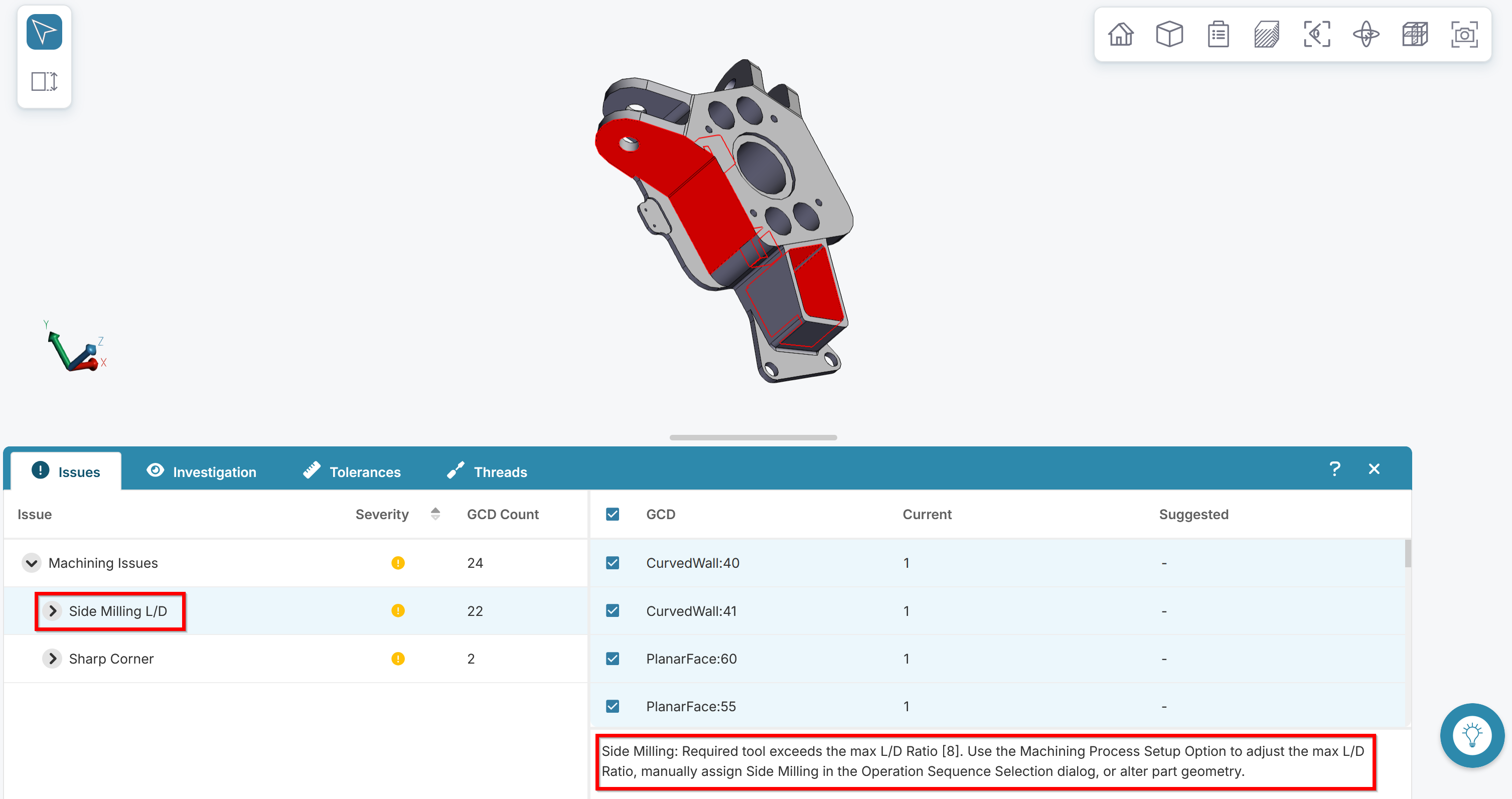

Next, we’ll investigate the aPriori’s Design guidance. The Design Guidance card will allow you to take a deeper dive into the cost driving features of the part; in this example we have many milling L/D ratios that exceed the recommended limits.

-

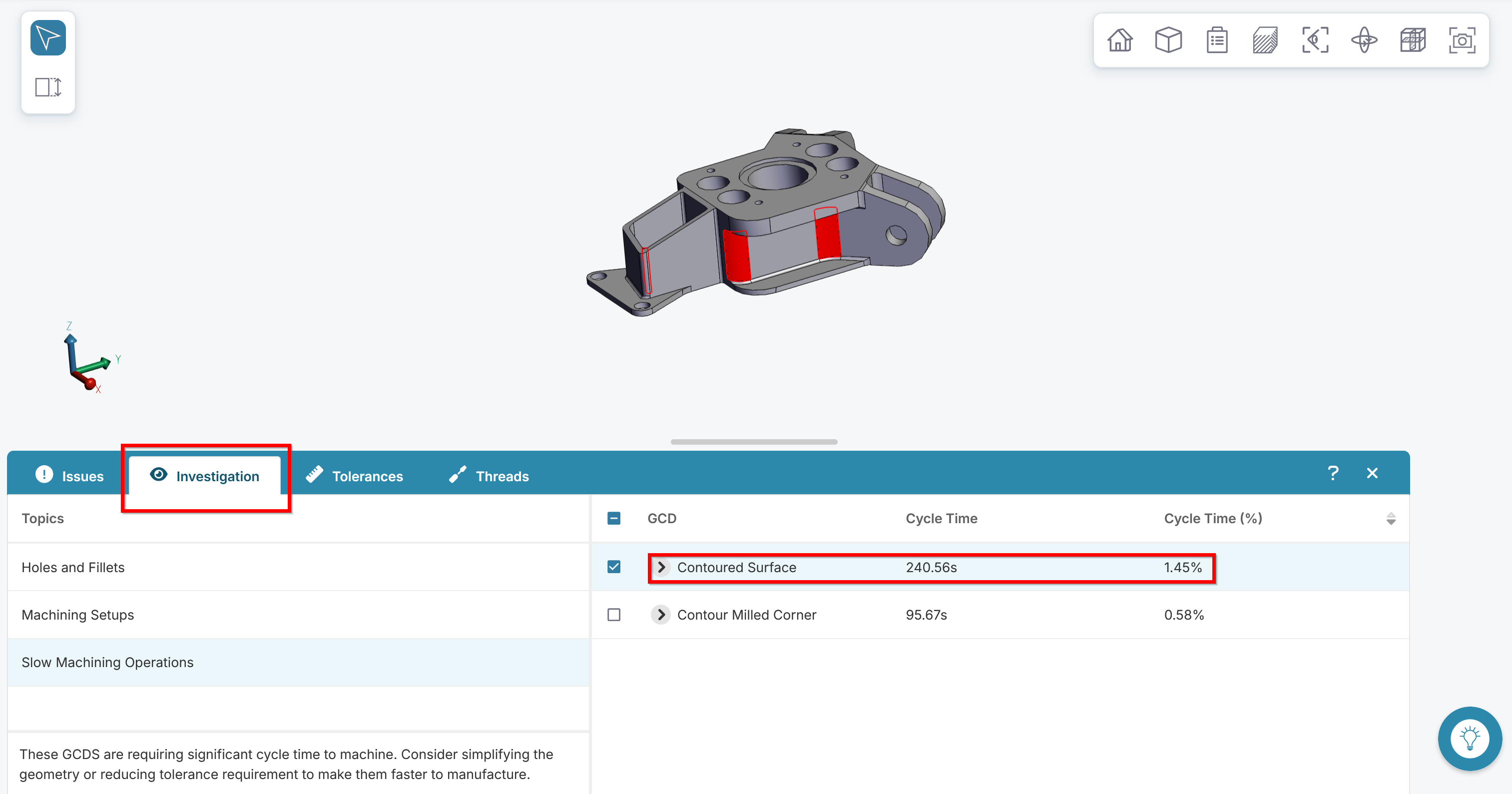

From the Investigation tab, we can see a breakdown of the features with the longest cycle time as well as the percentage of the total cycle time. This example shows two curved features that are slow to machine.

-

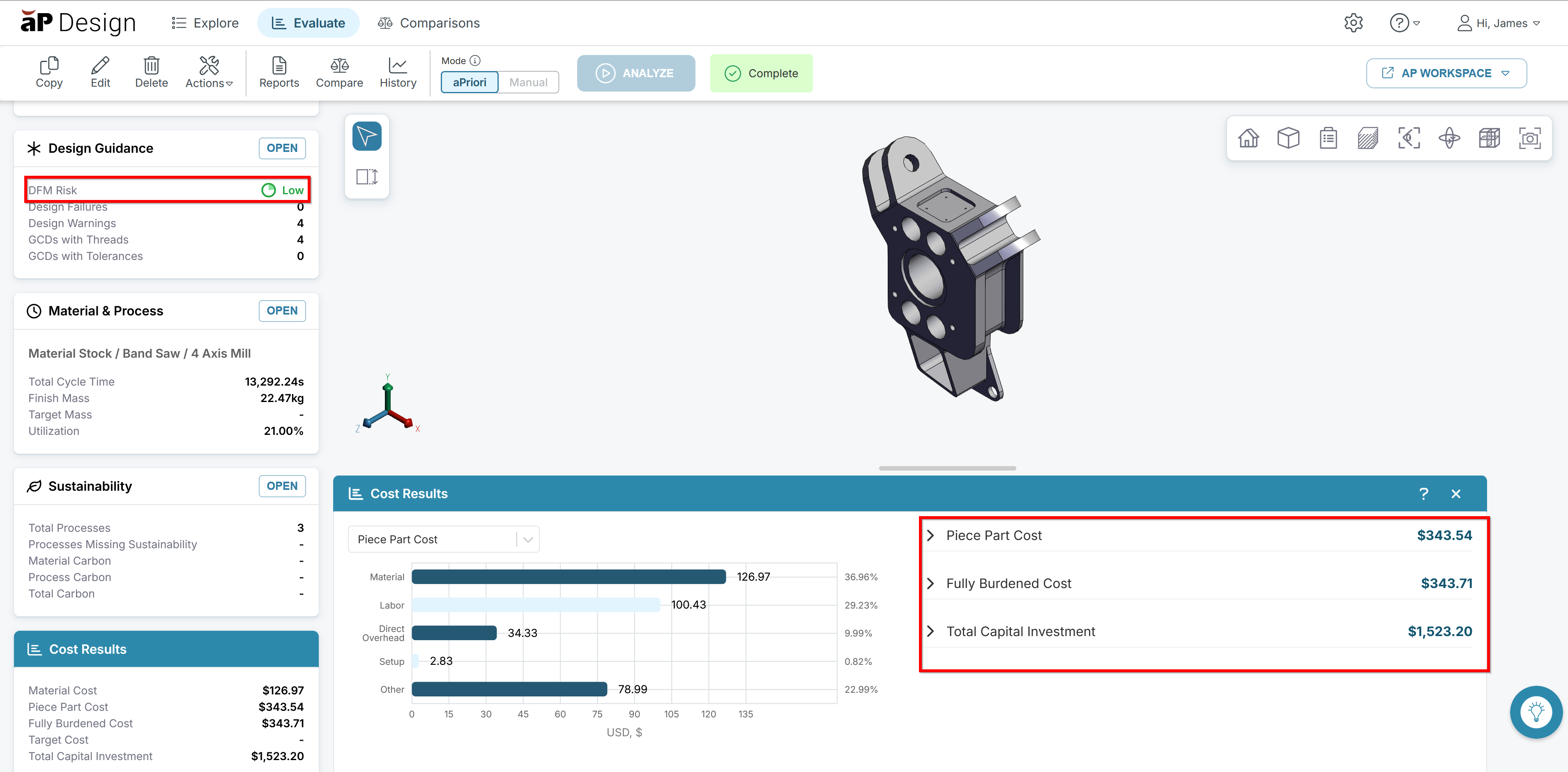

After adjustments are made to the CAD file, the updated file shows alleviation of manufacturing issues and adjustment of cost results.

Alternative Approach: aP Pro

We can realize similar results using the aP Pro tool: see the Design to Cost and DFM Guidance tutorial for more details.